DIY Overhaul or Minor Repair on Your Mini Excavator

Starting with minor repairs, maintaining your mini excavator is essential to ensure it runs efficiently and lasts longer. Regular upkeep and small fixes can help you avoid expensive breakdowns and keep your machine performing at its best. Here’s a step-by-step guide to performing a quick DIY overhaul or minor repair on your mini excavator.

1. Greasing the Slewing Bearing

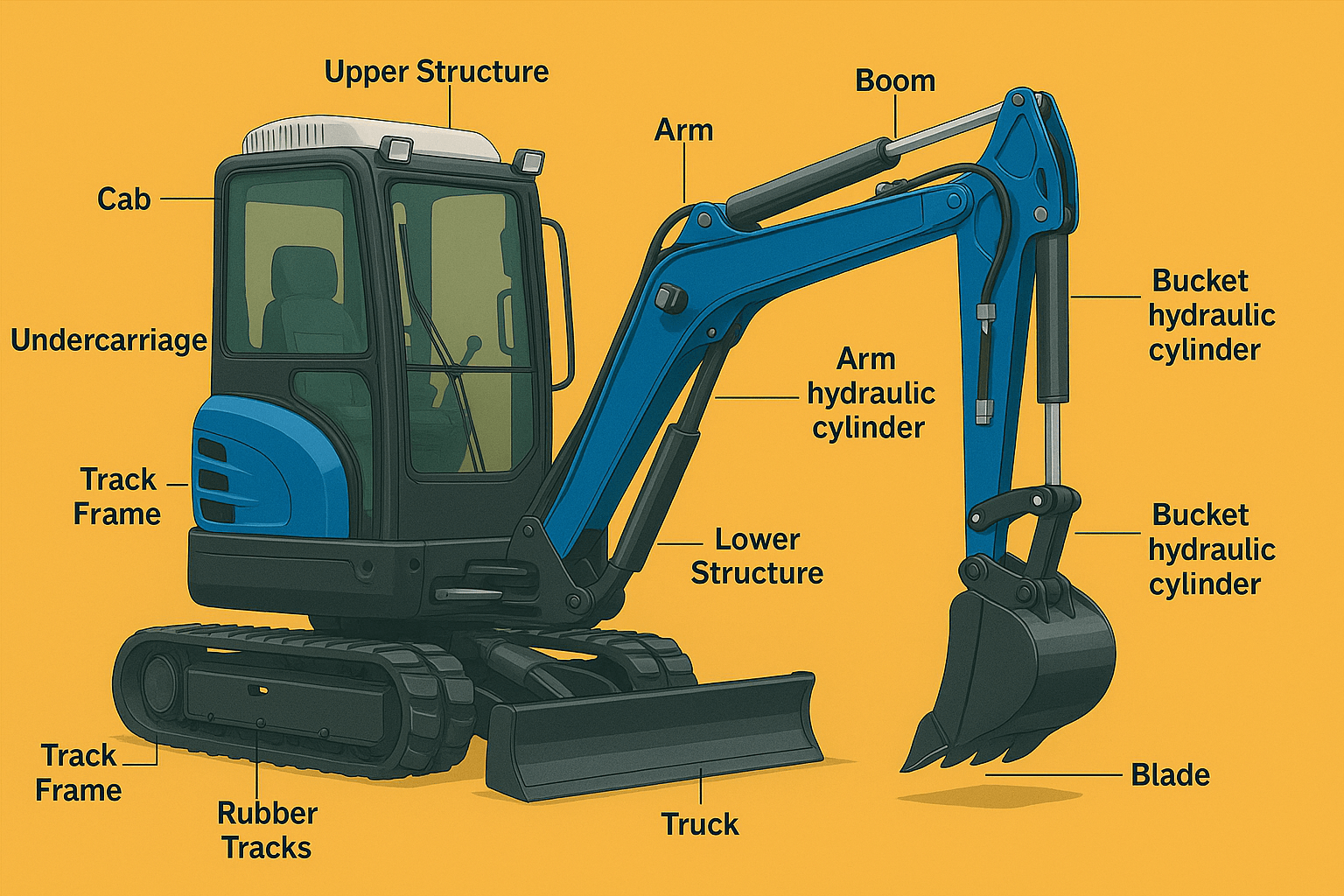

The slewing bearing is essential for the smooth rotation of your excavator. Regularly apply grease to the bearing to reduce friction and prevent wear and tear. This keeps the excavator’s upper structure rotating smoothly, increasing efficiency.

2. Greasing the Slewing Bearing Gears

In addition to the bearing itself, the gears that enable rotation need greasing. Proper lubrication of the slewing gears ensures longevity and prevents unnecessary friction that can lead to component damage.

3. Change the Engine Oil

Engine oil lubricates the internal components, reduces friction, and ensures optimal engine performance. Changing the engine oil at regular intervals keeps the engine running smoothly and prevents potential engine failures.

4. Change the Hydraulic Oil

Hydraulic systems are critical to the functionality of an excavator. Changing the hydraulic oil at recommended intervals ensures smooth operation of the boom, bucket, and other hydraulic components, while also preventing overheating and reducing wear.

5. Change the Hydraulic Oil Suction Filter Elements

The hydraulic oil suction filter helps prevent contaminants from entering the hydraulic system. Replacing the filter elements regularly keeps the hydraulic system clean, extending the life of the hydraulic components.

6. Inspect Fuel Pipes for Cracks or Bends

Fuel pipes are susceptible to wear and damage over time. Inspect the fuel pipes for any cracks or bends that may lead to fuel leaks, which can be dangerous and cause inefficiencies in fuel usage.

7. Change the Oil-Water Separator

The oil-water separator plays an essential role in maintaining the quality of the fuel. Regularly changing this component helps keep the fuel system free of moisture and contaminants that could damage the engine.

8. Check the Fuel Hose for Leaks or Cracks

A damaged or leaking fuel hose can affect the fuel system and engine performance. Check all fuel hoses for any signs of leaks or cracks and replace them immediately to avoid fuel wastage and potential hazards.

9. Replace the Bucket

Over time, the excavator’s bucket can wear out or get damaged. Replacing the bucket when needed helps maintain digging efficiency and ensures your excavator can handle tough jobs without difficulty.

10. Inspect the Bucket Connection

The connection between the excavator and the bucket is crucial for safe and efficient operation. Ensure that the connection is secure and free from any defects or signs of wear to avoid bucket detachment during use.

11. Remove the Traveling Handle

The traveling handle, used to move the excavator, may require removal for maintenance purposes. Follow the manufacturer’s instructions carefully when removing this component to avoid damaging the machine.

12. Replace the Seat Belt

For operator safety, inspect the seat belt regularly and replace it if it shows any signs of wear or damage. A functional seat belt is crucial for safe operation, especially when working on uneven or challenging terrain.

13. Inspect the Track Deflection

The track of your mini excavator plays a vital role in movement and stability. Inspect the deflection of the track regularly and make adjustments or replacements as necessary to maintain proper alignment and avoid uneven wear.

14. Maintain the Tensioner

The tensioner keeps the excavator’s tracks at the right tension, preventing them from becoming too loose or too tight. Regular maintenance of the tensioner ensures the machine’s tracks remain in good condition and perform optimally.

Keep Your Mini Excavator in Top Shape!

Maintaining your mini excavator through routine checks and minor repairs can save you time and money in the long run. Whether it’s greasing key components or replacing worn parts, a little effort goes a long way in ensuring your machine operates efficiently.

If you’re in the market for a high-performance mini excavator that’s built for durability and ease of maintenance, consider the TYPHON TERROR X Mini Excavator 2,500lb Trench Digger w/ Cabin. This powerful machine is equipped with a comfortable cabin, making it perfect for tough jobs. Click the link to explore its features and make your next project a breeze!