When one considers the foundation of contemporary infrastructure, trenching is absolutely essential. Whether you work for a construction business, have experience building, or enjoy do-it-yourself projects and want to install some pipes in your garden, knowledge of trenching is vital.

What is trenching?

Trenching goes beyond just excavating a hole in the earth. It’s about designing a long, narrow excavation that is absolutely vital for building projects. A trench’s dimensions are what define it, unlike a typical excavation, which could vary greatly in form and scale. Usually, a trench is deeper than it is broad, and its breadth seldom ever reaches 15 feet.

Installers of underground utilities, wires, pipelines, and drainage systems depend on these trenches. In civil engineering, trenches underlie our contemporary cities’ unseen veins, delivering data, energy, and water underfoot.

In construction, trenching is the process of narrow excavation under the surface utilizing a trencher, an earthmoving machine. Unlike a ditch, trenches are deeper than they are wide; more narrow than their length; unlike a hole or pit.

What’s the Difference Between Trenching and Excavating?

Though most trenches are excavations, not all excavations are trenches. Whereas a trench is any excavation more narrow than its length, an excavation is any man-made trench, hollow, or depression created by soil removal below the surface of the ground.

Though an excavation can take any form or size, a trench usually has a depth greater than its breadth and a width not more than 15 feet.

What Are Trenches Used For?

Civil engineering and construction tasks ranging from pipe laying to electric cable installation from sewage lines to telephone wire employ trenching.

Trenching is most usually utilized at the household level for establishing plumbing connections, excavating irrigation, and running power cables and heating system pipes. Trenching is utilized at the municipal level to establish city-wide power lines as well as drainage and sewage systems.

Types of Trenches

Their form, which relates to the intended use of the trench, determines the several kinds of trenches. Many elements influence the kind of trench utilized in a specific project, including the kind of soil, the amount of pipe or other conduit to be laid in the trench, proximity to surrounding structures, and the precise position of the trench.

These components taken together define the particular trench form. Trenching isn’t a one-size-fits-all operation. The type of trench you need depends on various factors, including soil type, the purpose of the trench, and the surrounding environment. These are some of the most often occurring forms of trenches:

Straight Trenches

These are the most straightforward, with vertical sides at 90-degree angles to the base. They are ideal for projects where space constraints demand a narrow trench.

Sloped Trenches

To prevent cave-ins, sloped trenches have angled sides. This design is particularly useful for large pipes, where stability is crucial.

Benched Trenches

Imagine steps cut horizontally into the trench walls. This style not only prevents collapses but also provides additional stability.

Bell-Bottom Trenches

These bell-shaped ditches have a narrower top than their bottom. Frequently used for foundations, they offer a solid basis while causing least surface disturbance.

The success of the project depends on the appropriate trench type being chosen. As a result, the trench’s location, the surrounding buildings, and the characteristics of the soil all affect the best course of action.

Staying Safe While Trenching

Any construction project starts with safety; hence, trenching is not an exception. Trenching is a possibly dangerous job because of the large gear and related hazards. Among the risks involved with trenching are these:

Cave-ins

In trenching projects, these account for the most mortality. Unbelievably hefty, the weight of the earth may catch someone without notice.

Falling Debris and Equipment

Workers are particularly at great danger from materials, tools, and even machines falling into a trench.

Hazardous Fumes

Working underground can mean exposure to dangerous gases and fumes, especially if the trench is near utility lines or chemical storage.

Earthmoving Accidents

Operating equipment in tight spaces increases the chance of accidents involving earthmoving machinery.

Slip and Fall Accidents

Moisture, debris, and uneven surfaces increase the likelihood of slips and falls.

Electrocution

Striking underground electrical lines can lead to severe injuries or fatalities.

To mitigate these dangers, the Occupational Safety and Health Administration (OSHA) provides guidelines that every construction site should follow.

Use Protective Systems to Prevent Collapses

A robust protective system is essential for trenches deeper than five feet. The options include:

Sloped Walls

By angling the walls, you reduce the risk of collapse.

Benched Walls

Creating steps in the walls adds stability and prevents cave-ins.

Shoring Systems

Supports like timber, jacks, or steel props hold the trench walls in place.

Trench Shields

These boxes act as a barrier between workers and unstable earth.

The appropriate solution will rely on elements such as soil type, water level, trench depth, and proximity to adjacent buildings. A trench kept under protection guarantees a seamless operation and protects personnel.

Identify Underground Utilities First

It’s important to find all subterranean utilities before ground is broken. Major damage and life endangerment might result from striking a gas, water, or electrical line. Legal requirements demand that you designate these wires by contacting local utilities—just call 811. This stage not only helps to avoid mishaps but also lessens project disturbance.

Daily Hazard Inspections

Safety isn’t a one-time behavior. Every day, look for risks or instability in trenches. Remove workers until safeguards are rebuilt if situations get dangerous. Maintaining a safe workplace and avoiding mishaps depend mostly on regular inspections.

Allow Safe Access and Exit

For trenches deeper than four feet, provide safe access and exit points like ladders or ramps within 25 feet of workers. Easy access ensures that workers can quickly evacuate in case of emergencies, reducing the risk of injury.

Buy or Rent Trenching Equipment?

Deciding whether to buy or rent trenching equipment depends on the frequency and scale of your projects.

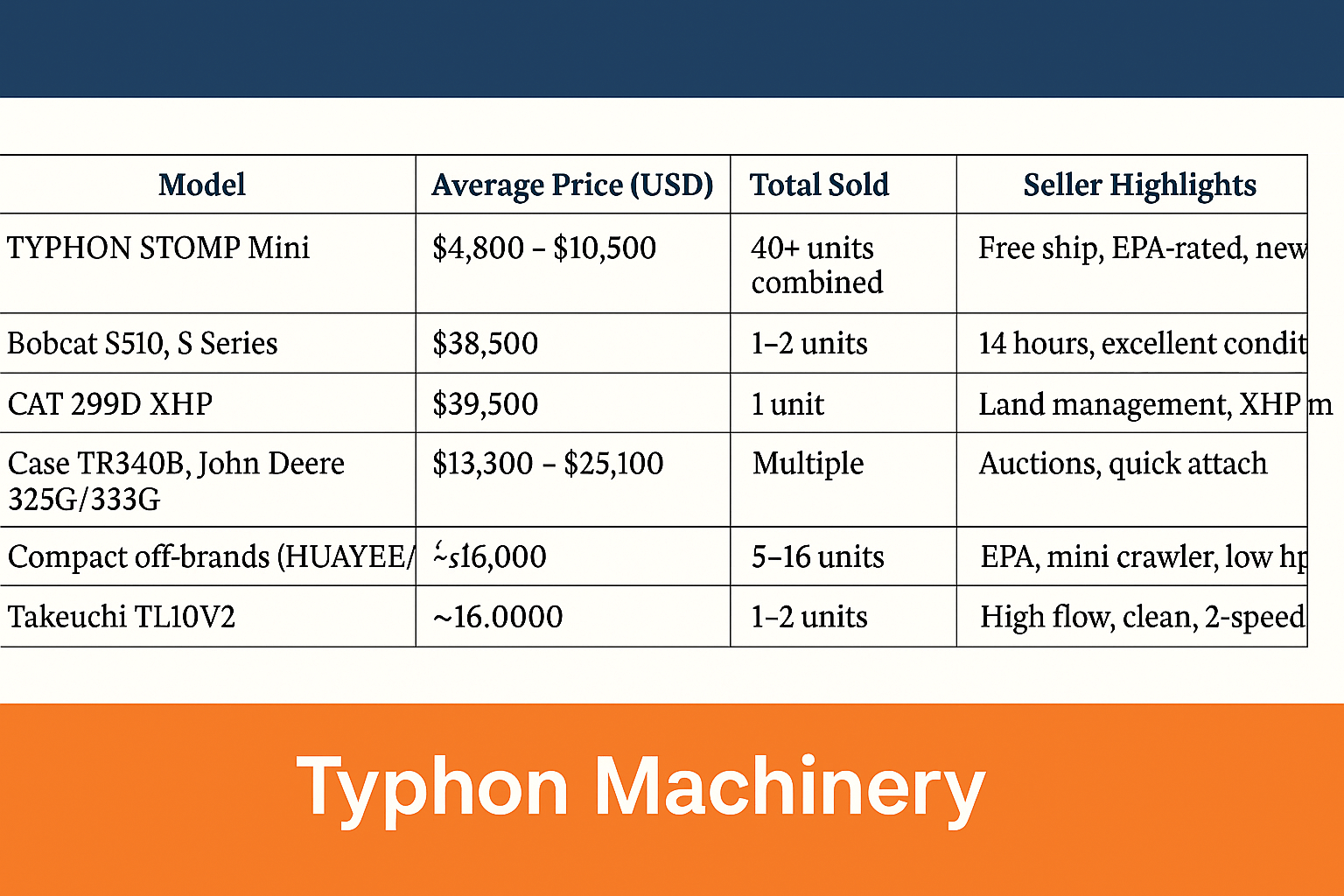

Advantages of Buying

Owning your tools might be quite affordable for contractors that trench often. It lets one customize and helps to minimize renting expenses. Still, running equipment also involves bearing repair and maintenance costs. Thankfully, businesses like TYPHON provide guarantees and lifelong support to help to allay these worries.

Advantages of Renting

Renting usually makes more sense for sporadic trenching requirements given budgets. You save the financial commitment of ownership by paying for what you use. Moreover, rental companies sometimes provide maintenance, thereby guaranteeing that the equipment is in perfect shape.

See experts who can evaluate your particular project requirements and advise the appropriate trencher to help you make the best option.

Conclusion

Whether you work for a construction business, are a contractor, or like do-it-yourself projects, trenching is a basic element of building. Effective projects depend on knowledge of the many kinds of trenches, safety procedures, and equipment choices. Following best standards and using appropriate instruments can help you carry out trenching activities effectively and securely.

For individuals who would want to learn more about trenching methods or equipment choices, think about consulting professionals in the field or going to seminars with practical instruction. Any trenching difficulty will be surmounted with the correct information and tools.