In the building and farming sectors, Kubota diesel engines are a brand linked with dependability and robustness. For people who depend mostly on agricultural equipment, knowing the lifetime of a Kubota diesel engine is vital. This handbook seeks to give diesel engine users, heavy equipment aficionados, and agricultural experts an understanding of the performance and lifetime of these strong engines. To help you optimize the potential of your engine, we will look at technical specifics, maintenance advice, and actual performance reviews.

How Long Will a Kubota Diesel Engine Last?

Offering a guarantee of two years or 2000 hours for normal usage and extending to three years or 3000 hours for key engine components, Kubota fully backs its industrial engines. Many users, however, find that these engines may exceed expectations and run up to 10,000 hours of operation with careful maintenance and care. This lifespan is evidence of the painstaking engineering that goes into every Kubota engine, not simply a boast.

Users must first understand what adds to their longer lifetime. Key is regular maintenance, including frequent fuel filter replacements and oil changes. Furthermore, greatly affecting the lifetime of the engine is the working environment and load type. Usually, as they cause less stress and component wear, light to moderate workloads help to extend engine life.

There is some magic in the design of these engines. Although Kubota engines are engineered to resist demanding circumstances, they flourish with regular, normal use. By avoiding too much strain and using the engine within its advised capacity, one may guarantee that the engine runs as best it can all during its lifetime.

Is the performance of Kubota diesel engines reliable?

Kubota diesel engines are well known for their dependability in performance. Well kept engines show remarkable durability in a variety of uses. Following consistent maintenance plans is the secret to keeping this dependability, as it helps avoid frequent problems that over time can compromise diesel engines.

For diesel engines, for example, usual issues are soot deposition and vibrations. Following advised oil change intervals and regular air filter cleaning help to minimise them. These methods ensure flawless functioning, therefore extending the life of the engine and improving performance.

Another very important component is stress management. Heavy chores or extended high-intensity effort over burdles your engine and accelerates wear and tear. Users can reduce the effect of stress on the engine’s components by controlling the workload and giving enough rest intervals, therefore increasing its operating life.

Addressing Common Diesel Engine Concerns

Not perfect are diesel engines, including Kubota’s; they have natural flaws. Common problems requiring consistent maintenance include soot deposition and engine vibrations. Preventing soot accumulation depends on a well-maintained air filter system, which also helps to lower engine efficiency and raise emissions otherwise.

Following a rigorous oil change calendar is just as crucial. Fresh oil guarantees enough lubrication of engine parts, therefore lowering friction and wear on them. Frequent oil changes also help eliminate toxins that over time can cause damage.

Apart from these procedures, employing premium gasoline and additives helps improve engine performance and lifetime even more. Clean gasoline helps to ensure that injectors and other fuel system problems are less likely, therefore improving engine performance. Using these techniques will help to greatly lower the likelihood of running across typical diesel engine issues.

Priming Tactics for Kubota Diesel Engines

Modern diesel engines from Kubota are user-friendly for operators as they have streamlined the priming procedure. Kubota engines can frequently restart easily after running out of gasoline, unlike previous versions, which needed manual priming. Usually all it takes to release any air and enable a seamless restart is just filling the tank and turning on the ignition.

Technological development has made Kubota engines simpler to maintain and more efficient. Complicated priming processes no longer cause operators to stress; this lowers downtime and increases general output. Priming is completely avoided if you make sure your fuel tank is constantly watched over and replaced before it gets critically low.

When hand priming is still required, Kubota offers precise directions and instruments to speed through the procedure. This guarantees that even older models may be restarted with little effort, therefore preserving their dependability and simplicity of use.

Kubota D722-E3B Engine Specs and Performance

Consider the Kubota D722-E3B model, which highlights the engineering brilliance of the firm. Using E-TVCS combustion technology—known for its complete burning and great cold start capability—this engine’s three-cylinder architecture guarantees flawless performance, and the great power output guarantees amazing longevity.

Though its intended use is light machinery, the Kubota D722-E3B engine has an outstanding lifetime. This engine can run for more than 5000 hours without overhauling with correct care. Many consumers have found that Kubota’s tiny diesel engines, with their dependability over long runs, routinely outlive rival goods.

The sophisticated engineering underlying the D722-E3B model emphasizes Kubota’s dedication to excellence and creativity. Those looking for dependable performance in small machines choose these engines as they are engineered to run consistently with efficiency.

Excavator with Kubota Engine

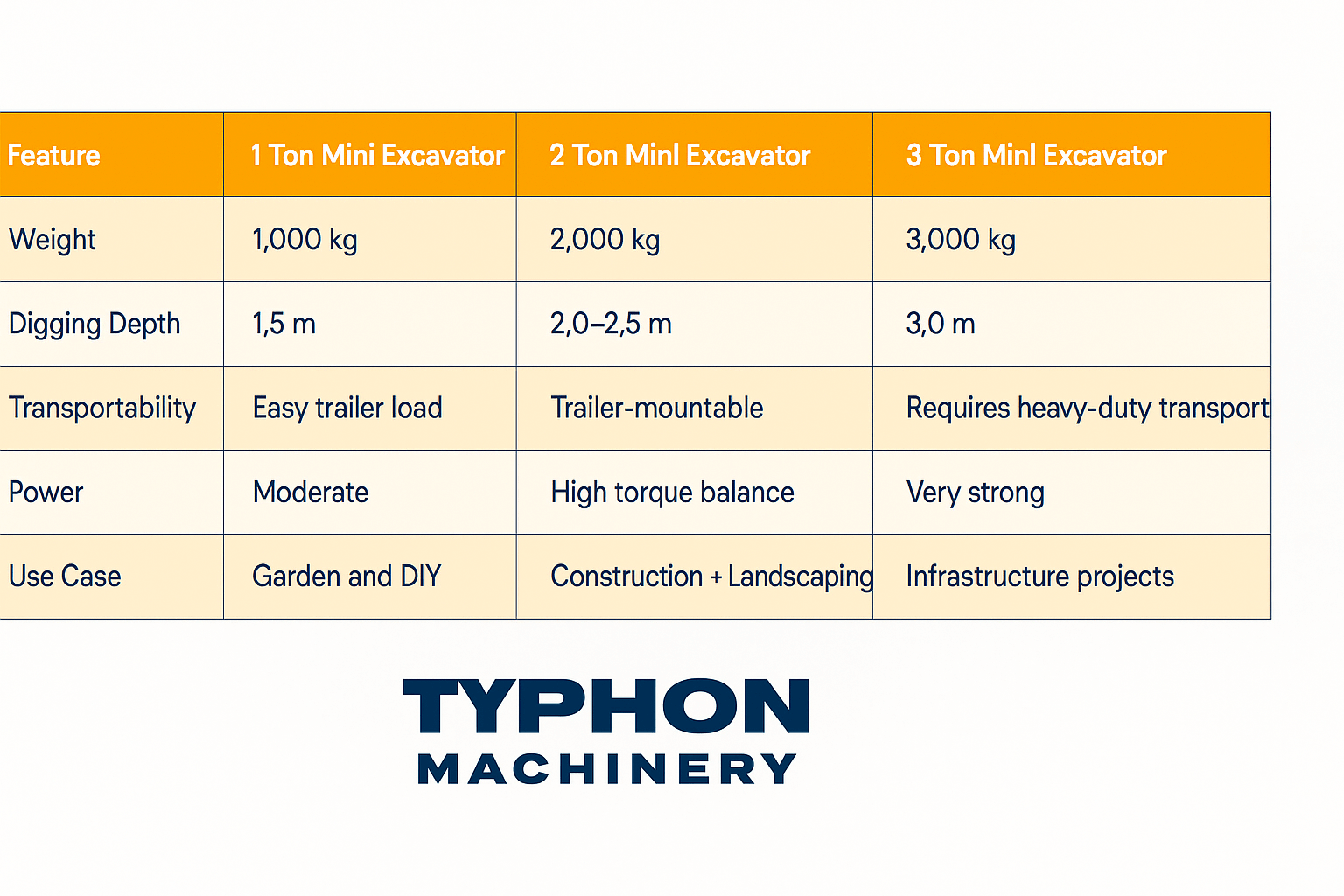

The 1-ton compact excavator Kubota generates running on the D722 engine finest illustrates his engineering ability. Small-scale building jobs and landscaping would benefit from this excavator’s all-terrain track design with strong dynamics.

With a maximum digging depth of 5.7 feet and a 2698 lbf digging force, this little excavator performs remarkably. The Kubota engine operates without overheating or damage, consistently even during extended running. Kubota’s dedication to providing premium, long-lasting engines is shown in its dependability.

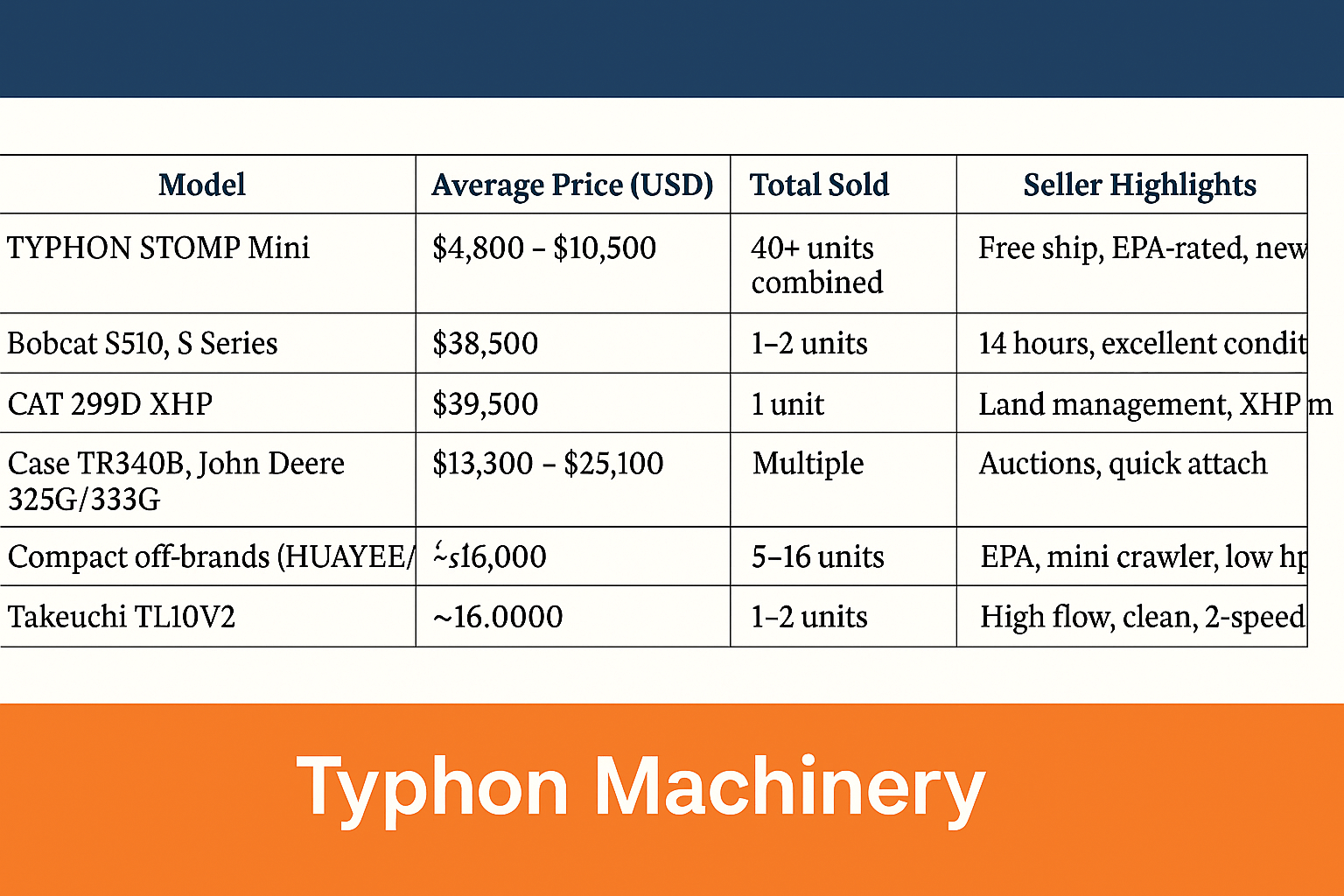

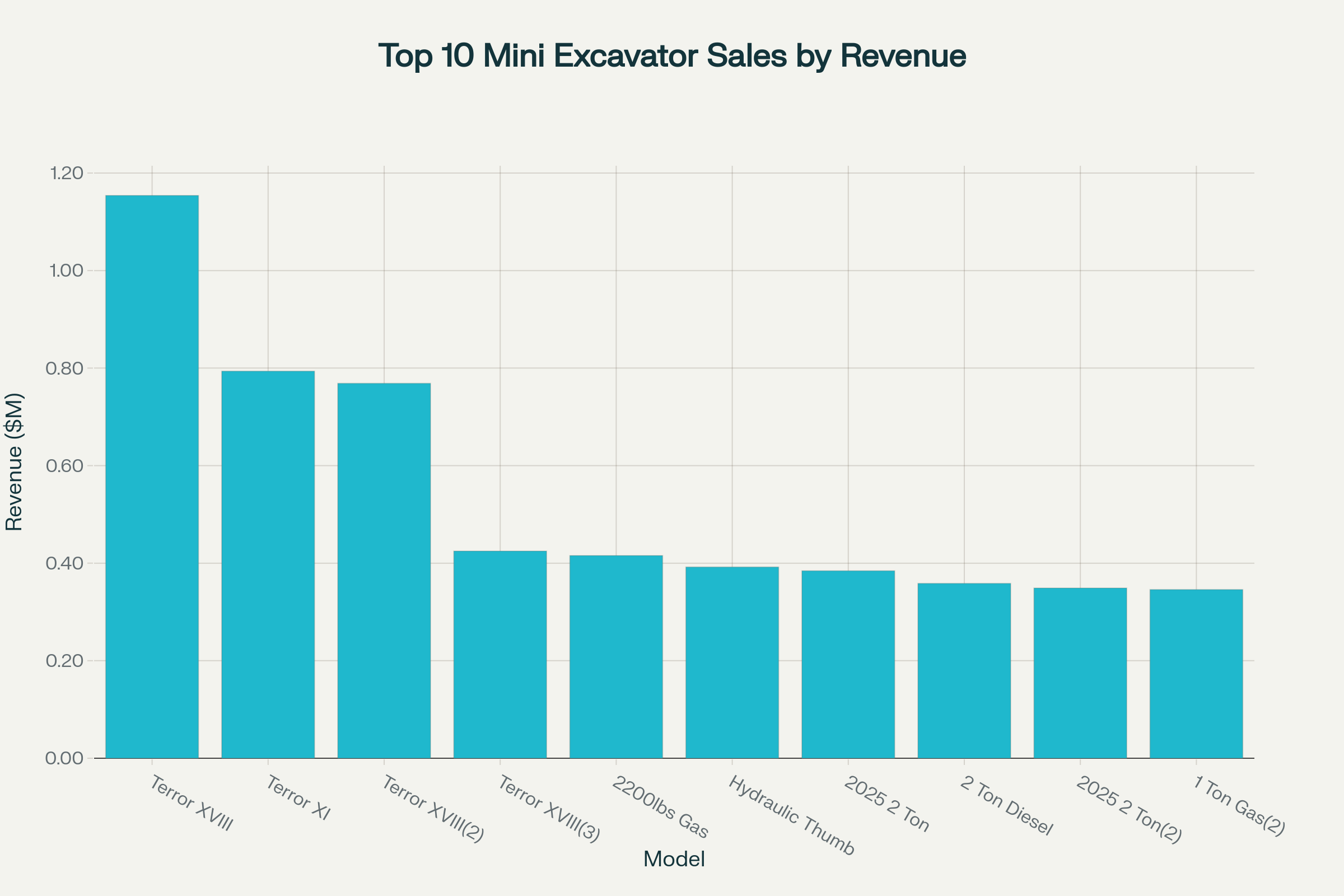

The D722 engine and the TYPHON excavator together highlight how brilliantly Kubota engines perform in practical uses. Professionals who respect dependability and efficiency choose them because of their capacity to function regularly under challenging situations.

Summary of Kubota Engine Advantages

All things considered, Kubota’s little diesel engines are known for dependability and longevity. For many different uses, including minor technical tools and building machines, they have evolved into a reliable choice. If you’re looking for a microexciter, the TYPHON track-mounted compact excavator running Kubota D722 has robust and long running power.

For those in agriculture, heavy equipment enthusiasts, and diesel engine users, Kubota engines’ proven lifespan and performance make them an outstanding investment. Understanding the maintenance needs and using best practices helps users to improve the lifetime and performance of their Kubota engines.

Their standing as top diesel engine producer is still derived from Kubota’s dedication to excellence and innovation. Kubota engines provide a consistent, time-tested answer for consumers looking for dependable, long-lasting performance.

Conclusion

A Kubota diesel engine’s lifetime is evidence of its remarkable dependability and engineering. Knowing how to optimize the engine’s capabilities is crucial for both heavy equipment aficionados and those working in agriculture. Users may increase the lifetime and performance of their Kubota engines by using best practices and following maintenance recommendations. See industry professionals or Kubota’s support network to learn more about improving the performance of your Kubota engine or investigate other resources.