The integrity and competitiveness in the hectic building sector calls for willingness to welcome new technologies. Hydraulic quick hits are a big improvement for tiny excavators. These innovative designs greatly increase the capacity and adaptability of small-scale excavation tools.

Gone are the days when changing out buckets and tools needed time-consuming manual effort with heavy hand quick hitches. Using hydraulic Quick Hitches for your mini excavators allows you to change attachments in a few seconds, therefore increasing output on any kind of work site.

For builders and contractors trying to simplify their processes, knowledge of this technology is very vital. Maintaining competitiveness in the sector depends on keeping up with technical developments, not only of which is beneficial as the sector changes.

Using hydraulic Quick Hitches can help you go in the correct path, whether your goals are higher safety or more efficiency. Explore this page to learn how these cutting-edge tools could transform your approach to excavation projects and provide unheard-of advantages for your regular job.

What are Hydraulic Quick Hitches?

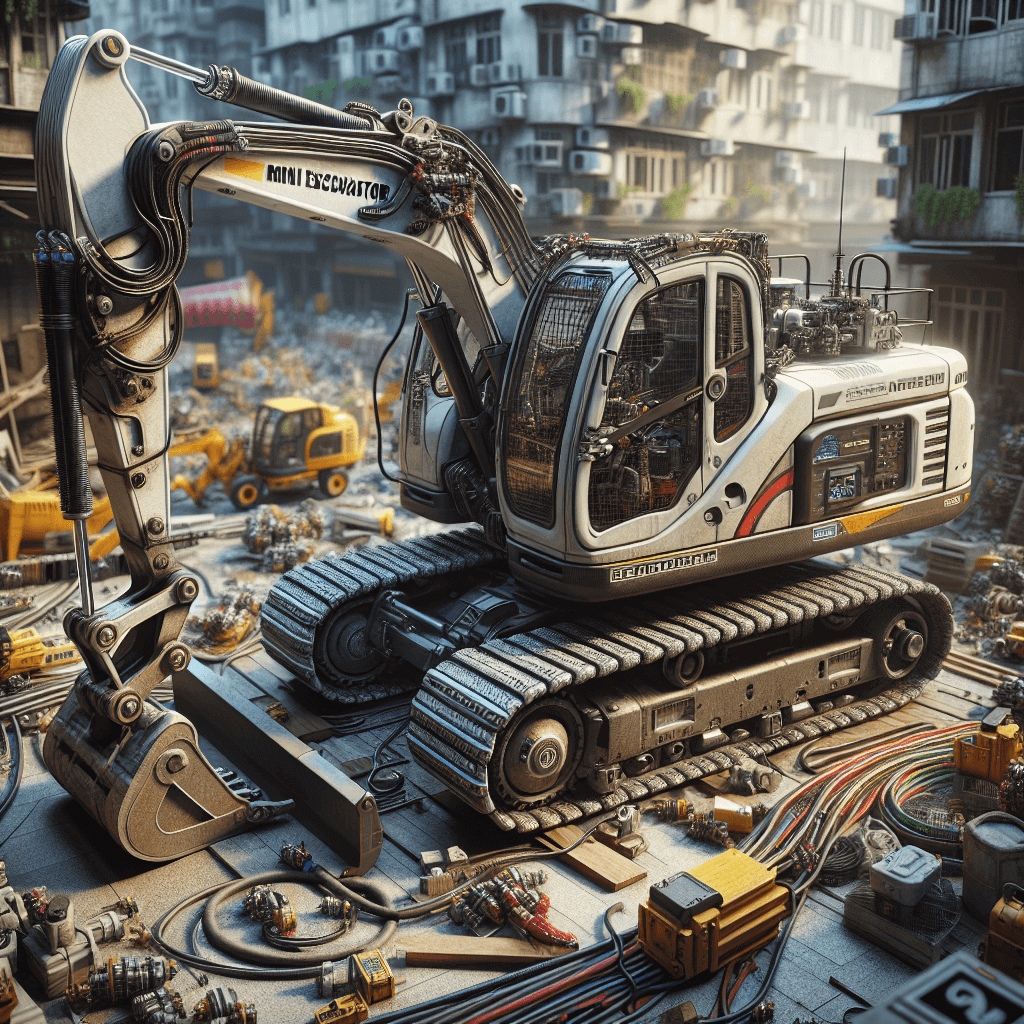

Modern gadgets called hydraulic quick hitches greatly improve the operation of mini excavators by allowing operators to rapidly and effectively swap attachments. These hydraulic systems basically let the excavator and other attachments—such as buckets, grapples, or augers—have a smooth connection without human intervention.

Using conventional mechanical systems, contractors may therefore go from one job to another in a fraction of the time it would take. Using hydraulic fast hitches for your mini excavators helps you invest in simplified operations and less downtime rather than just in an attachment.

The simplicity of usage hydraulic quick hitches provide is among its most obvious differences from their hand equivalents. Manual hitches may require operators to exit the cab many times to secure or release attachments, leading in lost productivity and increased safety concerns on job sites.

Hydraulic hitches let operators to make these modifications without leaving their seats, saving both time and energy. Equipment efficiency becomes critical when projects stretch limits with tighter deadlines and greater expectations; hydraulic fast hitches do just that by lowering labor effort while maintaining excellent performance levels.

Regarding applications in mini-excavation, hydraulic quick hitches find use in anything from utility work to building and gardening. Having a hydraulic fast hitch, for instance, lets a contractor easily go from excavating a trench to laying a bigger bucket attachment for backfilling without upsetting flow.

This adaptability allows operators to confidently handle various jobs instead of spending valuable time fumbling with hand alternatives. Moreover, as contractor tastes move toward technologies that increase on-site efficiency, more experts understand how important hydraulic systems are to contemporary excavation techniques.

Professional Views on the Advantages

Industry analysts have now come to see hydraulic rapid hitches as a major development in excavation technology. Especially, these tools let operators to easily change attachments without leaving the cab, therefore increasing worksite efficiency. BuildTech Innovations’ construction technology expert Greg Monroe claims that builders who have switched to hydraulic quick hitches may finish jobs up to 30% quicker than using conventional manual techniques. ” Teams can greatly maximize their productivity by quickly adapting tools for many uses—from digging trenches to lifting heavy loads,” Monroe says.

This idea is further supported by a recent Contractor Daily analysis showing an average increase of 20% in total job production during a six-month period for organizations using hydraulic quick hitches. This increase in output may be mostly ascribed to lower downtime and less delay resulting from hand equipment changes. By means of these sophisticated linkages, contractors are also using data analytics obtained from equipment performance indicators. This guarantees that every unit of time and effort invested helps to ensure that improved project planning and resource allocation follow from this, therefore assuring that every moment counts toward completion times.

Beyond just increasing economy, hydraulic quick hitches also greatly increase safety. Experts such as Sara Jenkins, a safety compliance officer in heavy equipment operations, stress how lowering human interaction not only accelerates but also reduces risks related to manual handling mistakes or accidents during attachment changes. While reducing operator stress, hydraulic systems provide constant force delivered straight from the excavator. Jenkins said at a construction summit last year, “Our focus has always been on creating safer working environments; adopting hydraulic technology has proved beneficial in enhancing site safety measures.”

In the end, the rise of hydraulic quick hitches represents a fundamental change toward contemporary methods in the excavation industry. These developments clearly go beyond simple operation as experts balance user experiences against conventional equipment approaches by objective comparisons of productivity measures and safety records. They change how teams approach all aspects of digging and lifting operations. As experts include this innovative technology into their processes for both profitability and improved project results, the data keeps mounting in favor of upgrading fleets with it.

Technological Developments Driving Adoption

Thanks in great part to hydraulic system technical developments, the scene of micro excavation is fast changing. Modern hydraulic fast hitches are designed with state-of- the cutting-edge technologies improving their efficiency and performance. For example, two-way controls let drivers to tighten attachments without leaving the cab, therefore saving a lot of switching tool time. This is a necessary part in modern building techniques as it not only simplifies processes but also maximizes machine use on the work site.

Integration of hydraulic Quick hitches with other machines also offers another major advantage. Many manufacturers are also creating attachments meant for fit with more general equipment ranges so that operators may easily move between jobs. This flawless connection lets one approach different projects—from excavating trenches to carrying huge loads—more flexibly. Industry experts point out this benefit—that being able to effectively replace attachments may help to reduce downtime and increase general productivity, therefore reducing costs and enabling quicker project completion timeframes.

Emerging advancements are increasing the adaptability of hydraulic quick hitches even further. Some businesses, for instance, are looking at automated technologies that improve safety and accuracy throughout operation. These cutting-edge technology include sensors that provide real-time data on weight distribution and attachment state, therefore enabling operators to maintain ideal performance and reduce the hazards connected with inappropriate hitching techniques. Best practices in hitch selection will change with these characteristics as they become industry standard practice, motivating building experts to remain current with the most recent solutions.

Contractors that embrace these ideas into their daily operations get themselves ahead of the curve in a crowded industry. As developments continue to alter how building projects are carried out—making them safer, more efficient, and finally more profitable—mini excavators fitted with hydraulic fast hitches seem to have bright future.

Selecting Correct Hydraulic Quick Hitch

To guarantee best performance and safety, numerous important considerations should be given when choosing hydraulic quick hitches for your mini excavators. First and most importantly is weight; you will want a hitch that enhances the lifting capability of your machine without surpassing it. Although a high-duty hitch would look great, if it would be too heavy for your excavator it might cause stability problems or even damage during operation. Compatibility is another important factor; you should make sure the hitch matches both any attachments you intend to use and your specific model of mini excavator.

One cannot stress lift capabilities apart from compatibility and weight. Knowing the maximum lift capabilities of your equipment and the quick hitch can help you prevent mistakes on site. For example, companies like Tomcat and Steelwrist maximize efficiency by providing versions catered for various weight classes, therefore guaranteeing safety. Industry professionals say that choosing a recognized brand may greatly affect general user happiness; those who bought well-reviewed hydraulic quick hitches usually reported fewer downtime due to equipment faults and better transitions between different attachments.

Extended hydraulic quick hitches for your mini excavators depend much on maintenance as well. Typical checks should concentrate on hydraulic fluid levels, pivot point wear and tear, and any indications of leakage or corrosion. For instance, a basic weekly check of hose connections might help to avoid any operational problems during important project activity. In addition to improving operation, cleaning dirt and trash from the hitch after every usage lowers corrosion risks over time, hence extending lifetime.

Contractors may significantly increase operational efficiency by keeping these factors in mind when selecting hydraulic quick hitches for their mini excavators—weight, compatibility, lift capacity—and by adhering to regular maintenance procedures, therefore conserving their investment in gear.

In general, Riding the Future with Hydraulic Quick Hitches

For mini excavators, hydraulic quick hitches fundamentally alter things. They improve operating safety and efficiency as well as have major positive effects on the surroundings. These hitches assist to lessen the carbon impact of building operations by cutting fuel use and speeding project completion. This is vital as the sector aims to satisfy environmental targets in a fast changing scene.

Future developments in equipment will, according to experts, keep innovating how contractors carry out their work. Growing integration of smart technology and automation might change methods of mini-excavation.

Using hydraulic quick hitches for your mini excavators is about leading the charge toward a more responsible and efficient future in construction, not just about keeping up. Those trying to remain competitive while giving sustainability first priority must use this technology.