Excavators are a crucial part of the construction equipment and are utilized for an array of purposes such as building work consisting of roadside repairs, landscaping, and mining. They are available in all sizes, ranging from mini excavators with seven metric tons to large models with 45 metric tons.

Some of the excavators are equipped with tracks, while others are attached with loads on the back. Excavators are quite an expensive piece of equipment, so it’s mandatory to maintain them properly. Keeping the excavators in good condition may save you a considerable chunk of money in the long run. However, if you do not pay heed to its maintenance, it can take a toll on your pocket. Surely nobody wants that.

So you must know how to maintain the excavator efficiently for its longevity. This blog will delve into some ideas for the proficient maintenance of your excavator.

Have a consistent use of oil for your excavator

Oil is crucial for the proper functioning of the vehicle. After fuel, oil has a preeminent place in the functioning of the excavator that features hydraulic systems. You need to invest in oil that is superior in quality and avoid using degraded oils for your machinery. It is relatively easy to recognize the degraded oil as it changes colors and may become filled with particles. Hydraulic oil, however, remains clear even when the needed additives break down.

Heavily used systems like hydraulics have special requirements, and if you use low-quality oil, then its protective power may give rise to critical issues such as hydraulic failures. Moreover, hydraulic oil is essential for keeping the whole system devoid of water and protecting it from rust and degradation. Though it may seem costly to you to invest in good quality oil, but it is an investment worth having for the vehicle’s proper efficiency.

Go for some grease

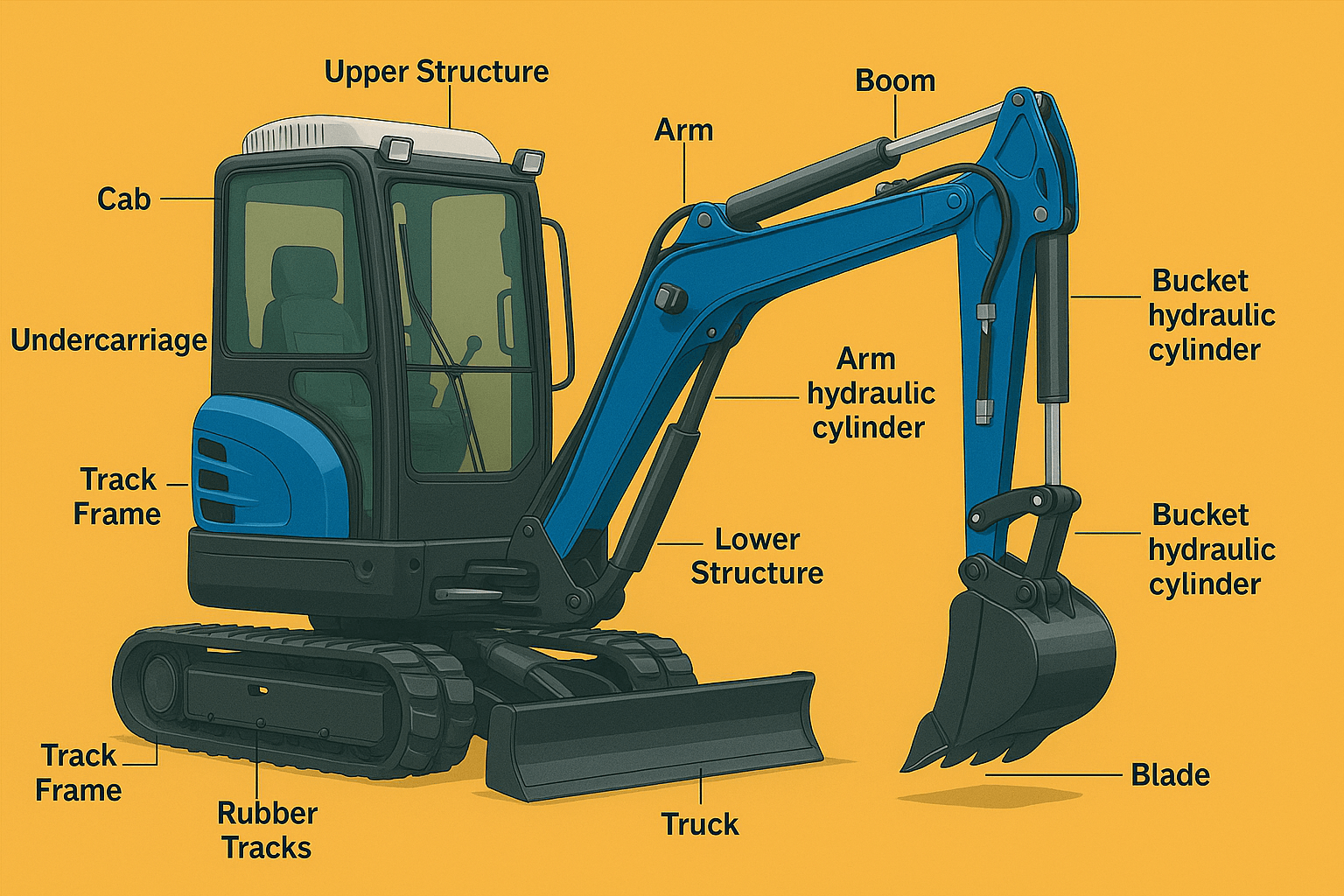

The grease is never nasty for the excavator. Lubricating the pivot points such as bushings, pins, buckets, dippers, and boom leads to a smooth operating excavator. The excavator might be difficult to repair but luckily easy to maintain. However, take care of some precautions as you should not use lubricants too much as they get messy and take a long time to clean.

Invest in the best buckets

Another factor for the longevity of the excavator is using an appropriate bucket. You need to make sure that you choose the one that can handle even the densest soil you excavate when working on the projects.

The depth of the soil you excavate also impacts the type of bucket you need. It may be a regular, ditch, or trench bucket. In the end, ensure that the bucket attachments are built well. The plates such as the cutter, sidebar, and bottom wear are specifically designed to absorb wear and tear that will prevent you from replacing your bucket very soon.

Do not avoid track tension

Excavators which do not run on the packed soil, asphalt, or concrete tracks must be appropriately aligned and kept at the correct tension. In case the tension is too tight, the wear and fuel consumption may enhance exponentially. On the opposite side, if there is not sufficient tension, the tracks can come off while turning or maneuvering.

Modern mini excavators usually consist of rubber tracks that react differently to rough terrain and higher speeds. That is why most of the wear happens during the sprockets. Although the rubber tracks can stretch, this can be easily fixed using track adjusters to move the idlers and maintain the proper tension level.

Changing Air and Fuel Filters

The efficient maintenance of the air, fuel, and hydraulic filters is essential in the maintenance requirement, especially for the equipment operating in dirty or wet conditions. You must refer to the operator manuals and read and follow the instructions carefully while changing air or fuel filters.

General preventive maintenance

The excavators need to be maintained regularly. Even when there is no work to be done with the excavators, you still need to use them. Even if you are using it for some random purpose, that does not matter. But the oils need to keep flowing and all the moving parts are lubricated.

The task of making preventive maintenance for your earth-moving equipment should be a regular part of your daily routine; it can surely be beneficial in many ways. You do not need to pay attention only to the bigger parts; the smaller parts are as crucial as the bigger ones. Keep the air filters, lights, gearbox, and fuel filters in good shape so that they run for a longer time without many complications to confront.

Maintaining your excavator efficiently is the key to maximizing its performance, reducing repair costs, and ensuring its longevity. By following a consistent maintenance schedule, using high-quality parts, and addressing issues proactively, you can keep your machine in peak condition for years. Whether you’re a contractor, operator, or equipment owner, investing time in proper excavator care will pay off in reliability and productivity. Start implementing these maintenance practices today and get the most out of your excavator!