Today we’re going to look at the small excavator and talk about all the crucial things you need to know. This article will describe the many sizes of mini excavators, what kinds of work they are good for, how they are different from regular excavators, how to pick the correct mini excavator for a project, and more. This page is for you if you want to know anything about small excavators.

The micro excavator can do most of what an excavator can, but it can also work in tight spaces.

You may call the mini excavator a lot of different things, such the mini ex, little excavator, mini digger, mini hoe, and compact excavator. This little compact excavator can execute any kind of accurate digging, no matter what you name it.

Mini Excavator: The Basics

What Constitutes a Mini Excavator?

A boom, dipper (or stick), and bucket are all connected to a cab that sits atop a house that turns. Most houses can turn all the way around. You can choose to put either tracks or wheels on small excavators.

The Size Category of a Mini Excavator

Mini excavators are those that weigh less than 4,535 kg (9,999 lbs) when they are working. The tiniest little excavator can squeeze through a door. The buckets on these machines may be anywhere from 12 to 24 inches wide, and you can always swap them out for a different attachment to do any job. But many businesses call their little excavators “compact excavators.” Usually, compact excavators can only lift 18,000 pounds. But most businesses include both micro and compact excavators in the same group.

Common Jobs for Mini Excavators:

People mostly use small excavators for mild demolition, moving materials, removing stumps, building things, or landscaping.

Mini excavators are commonly utilized for modest construction and landscaping jobs since they can do these things. These are:

- Putting in pools and hot tubs

- Demoing tiny structures

- Fixing broken sewage lines

- Cutting down trees

- Digging graves

- Renovations at home

- Projects for landscaping

- Uses on the side of the road

- Digging projects in general

How to Choose The Right Mini Excavator For Your Project

Planning ahead is the greatest method to choose the proper excavator for a job. Knowing what the excavator will do on site will help you choose the right one. So, your task can really get done faster. Instead than attempting to make one piece of equipment fit for several operations, it can be better for a job to hire the correct size equipment for what it needs.

The Mini Excavator VS Standard Excavators

Both the tiny excavator and the standard excavator have their respective roles and applications. This implies that a tiny excavator could be better for some projects than a regular excavator. You should always pick the sort of equipment you need based on the needs of the project, not on your tastes. This helps to ensure that all tasks are focused on getting things done quickly and efficiently.

A Heavy Machine That Is Smaller and Lighter

Mini excavators are smaller and lighter, which means they leave less scars on the ground and do less damage to the top. Mini excavators, like regular excavators, can have tracks or wheels, depending on the job and the type of ground they will be working on.

Good for busy or small project sites

Mini excavators are more suitable for busy job sites or when you need to operate around other types of equipment since they are compact. They are not only simpler to drive over parking lots, but they are also easier to move from one project to the next. Even if they are lighter, you should still confirm that a trailer can hold the weight of a piece of equipment before putting it on.

A Heavy Machine with Many Parts

Mini excavators are used for less severe jobs than regular excavators, which means they last longer. You can add all kinds of attachments to them, just as you do with regular excavators, to make them more useful.

Mini excavators may make projects go more smoothly.

It can be far more effective to rent a tiny excavator for each work than to try to use the same one for all of them. You may find a wide range of mini excavators and accessories near you by searching for them on Typhon Machinery.

Attachments for a Mini Excavator

A dozer blade, hammer, auger, grapple, or breaker are just a few of the attachments that may be used with small excavators. You may hire all of these accessories and more. Here is a more full list of mini ex attachments:

- Buckets and couplers, such as…

- 4-in-1 bucket ditching bucket

- Bucket with a V shape Bucket with a trapezoid shape

- Grab the power tilt pin

- Power wedge and other things

- Thumbs

- Rippers

- Rakes

- Hammer

- Augers

- Chuck the blades

- Grapples, such the rotating log grapple, the rotating utility grapple, the wood processing grapple, the demolition grapple, etc.

You may even add dozer blades to mini excavators to assist them move things around on the job site. Also, a dozer blade attachment can make the machine more stable, especially if it is a wheeled mini excavator. Mini ex attachments take the place of the bucket at the end of the boom, which makes the equipment more useful.

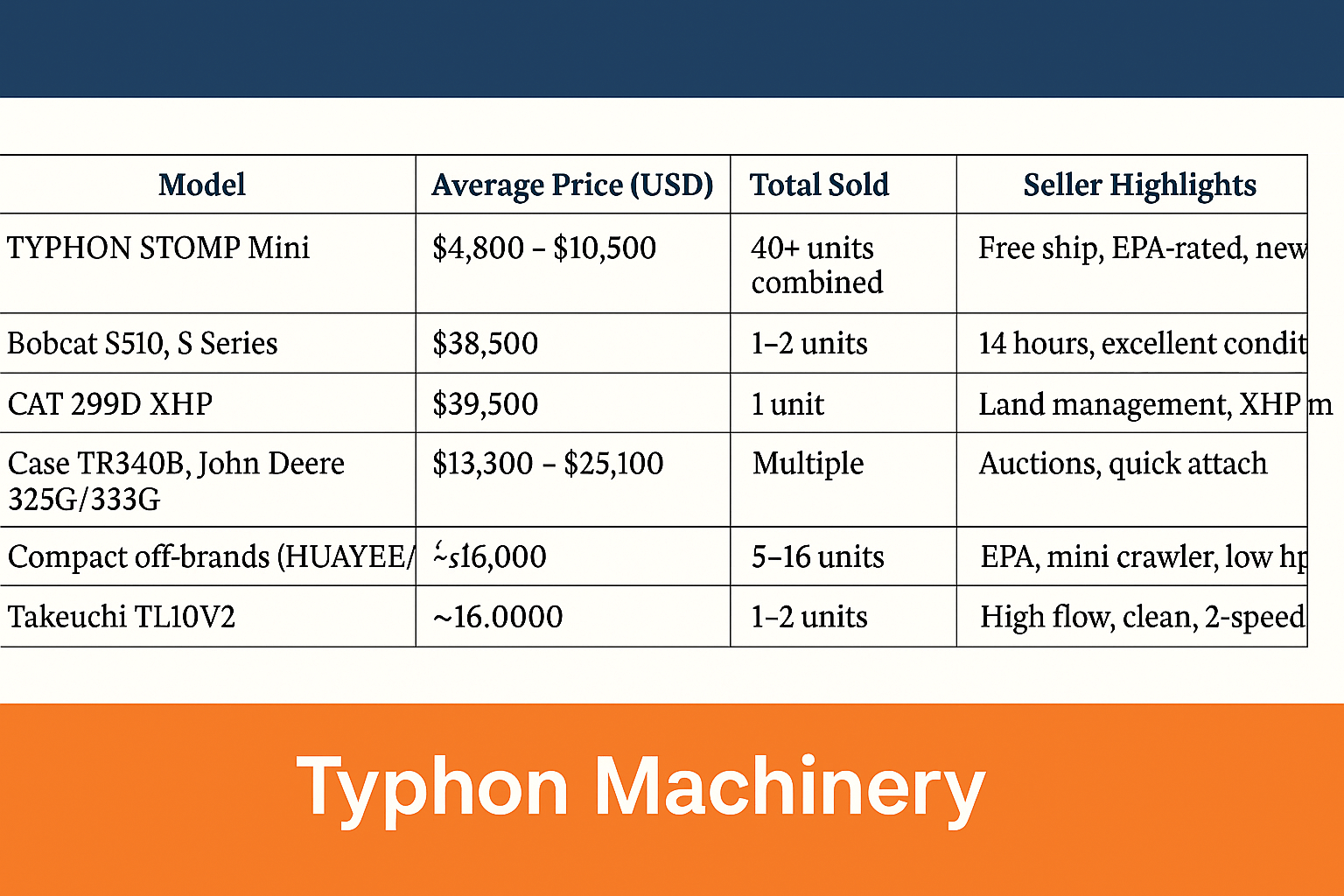

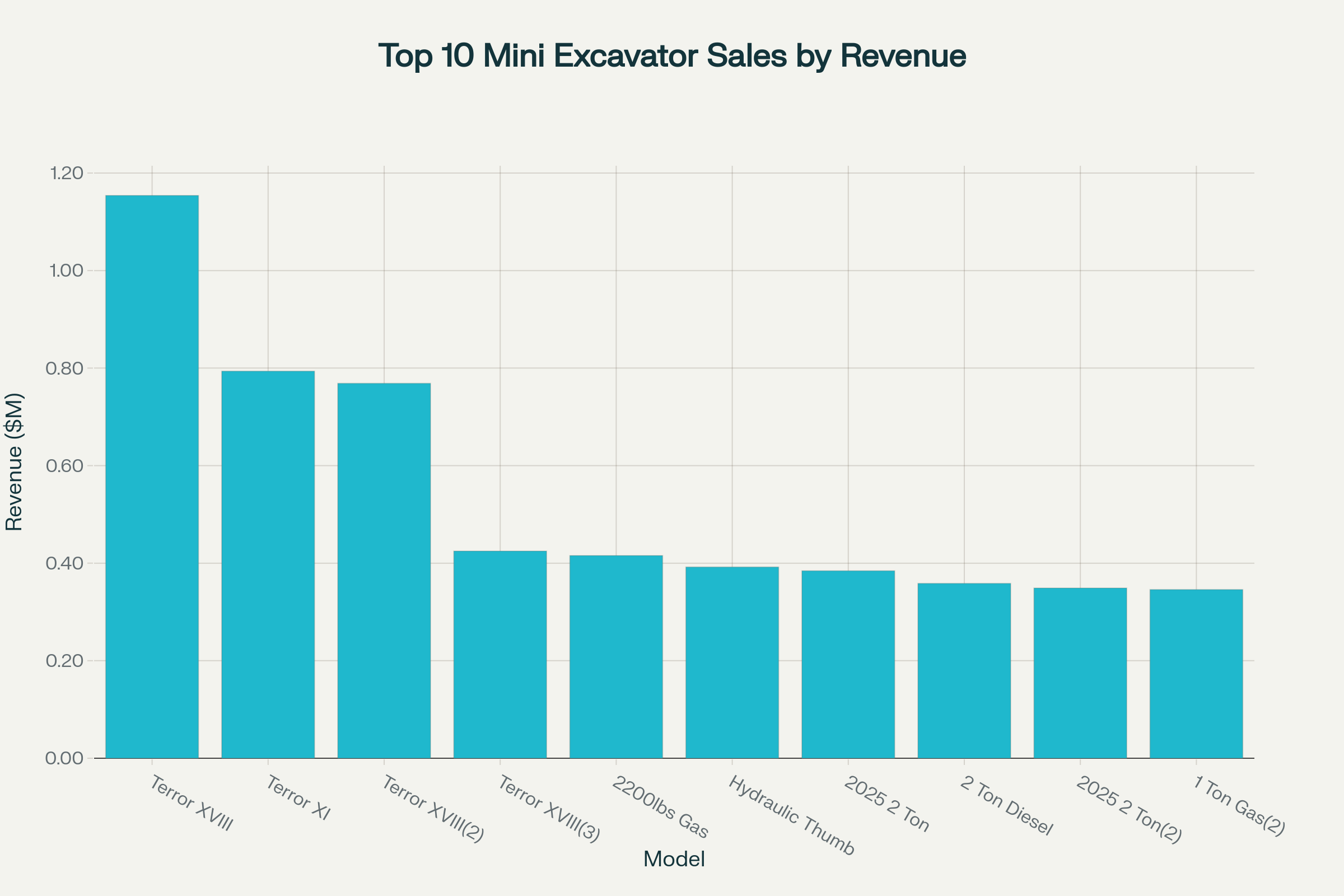

Manufacturers & Models of Mini Excavators

There are many different companies that make mini excavators, whether you want to buy one or rent one.

Caterpillar

Caterpillar, or CAT for short, was started in 1925 when the C. L. Best Tractor Company and the Holt Manufacturing Company joined forces. The Holt family is also responsible for the continuous-track system.

Caterpillar is one of the most well-known names in heavy machinery and equipment, and it is also one of the biggest corporations that makes heavy machinery in the world.

The CAT 305E2 CR is a small hydraulic excavator that weighs 11,443 pounds and has a swing boom that produces 40.2 horsepower. This is a mid-range compact excavator that may be used with a number of attachments to help with all parts of a job.

Yanmar

Yanmar is known as the home of the diesel micro excavator. The company makes eight distinct compact excavators, six of which have a genuine zero tail swing cab. Yanmar thinks of themselves as a pioneer in small equipment since their products are fuel-efficient and flexible.

The Vi050-6A is a small excavator that can swing and spin all the way around on its own track, making it possible to dig and trench in very small areas. This excavator has a digging depth of 12 feet 3 inches and an operational weight of 10,417 pounds. It features a Final Tier 4 Yanmar diesel engine with 39 horsepower.

Bobcat

Bobcat is a well-known maker of skid steers, which are machinesa that move things around. The Bobcat R-Series Excavators are designed to make digging easier than ever. They come in both compact and full-sized versions. There is a Bobcat excavator for any project since they come in different dig depths, arm configurations, and tail swing styles.

Bobcat makes tiny excavators that weigh from 2,593 to 18,977 pounds. The weight can go over the normal range for a “mini” excavator, much like with Hitachi’s small excavators. The Bobcat E10, E20, E26, E32, E35, and E42 all weigh less than 10,000 pounds, which is the limit for a mini.

The Bobcat E35 Compact Excavator has a two-speed travel feature, an innovative hydraulic system, and no tail-swing. This is a popular mid-range model that may be used for any job.

JCB

JCB makes a lot of various types of excavators, including full-size and small ones. Mini and compact excavators are made to be very comfortable, easy to control, reliable, easy to maintain, and perform well. These are the five things that JBC makes sure are in all of their tools.

The JCB 18Z-1, 19C-1, and 8029 compact excavators are easy to move and perfect for little jobs. They give the operator precise control and a great workspace. Their most popular little excavator is the 18Z-1. The 18Z-1 was made to make more money and cut down on downtime. It weighs 1,749 kg (3,856 lbs) and can dig down to 9 ft 4 in.

Hitachi

Hitachi is recognized for and focuses on excavators and excavators only. They have sold more than 2.5 million excavators throughout the world. They now produce more than 30 kinds of excavators. Some examples are foresters, wheeled excavators, mining excavators and shovels, construction/production excavators, and reduced-tail-swing excavators.

The ZAXIS Dash-5 models are “compact excavators” that come in a range of operational weights, from 1,720 kg (3,790 lbs) to 6,145 kg (13,547 lbs). The ZX60USB-5 is the largest compact excavator. It weighs just over 4,535 kg (9,999 lbs), which is the weight limit for a “mini” excavator. Hitachi’s tiny yet powerful compact excavators may be useful on any project site.

Potential Hazards & Safety Protocols for Mini Excavators

Using any form of big machinery might be dangerous. Always be careful and only use heavy machinery after getting the right training.

The US Occupational Safety and Health Administration (OSHA) says that workers who are responsible for operating heavy machinery, such as mini excavators, must be well-trained to make sure they do it safely. Never use a piece of heavy equipment that you haven’t been taught on. Always ask for instruction first.

Many of the safety rules for small excavators are the same as those for regular excavators. Some of them are:

- Putting on a seatbelt

- Before utilizing the equipment, make sure the mirrors are clean and adjusted. Never carry riders in a bucket.

- Before you start digging, look over the blueprints for the project site and the state of the work area.

- Not making abrupt moves

- Do not ever dig under a tiny excavator.

- Wearing clothes that are easy to see, hard helmets, ear protection, and face masks as needed

- Driving on a road that is as flat as it can be

- Staying away from rocky and uneven ground

Before trying to raise something with a small excavator, make sure you know how much weight it can handle and how high it can lift things. Stop and talk to a supervisor if you ever feel unsafe using a mini ex or any other type of equipment.

The History of the Mini Excavator

The first steam shovel was used to make the excavator, which is where the tiny excavator got its start.

William Otis came up with the idea for the steam shovel. The machinery would ride on train lines and could carry up to 300 cubic yards of stuff per day. People utilized this equipment to build the Panama Canal and excavate the bases of early buildings. In 1931, the final steam shovel was sold, and hydraulic shovels took its place.

In 1882, Sir W.G. Armstrong & Co. built the first hydraulic system. Kilgore Machine Co. then used this technology to make the first hydraulic excavator 15 years later.

There are two different stories about how the small excavator came to be. There is the “first” tiny excavator, called the “smalley,” and the first self-propelled mini excavator, called the YNB300.

The Smalley Mini Excavator

Richard Smalley came up with this tool, which is known for being the first small excavator. The Smalley excavator doesn’t have a real engine and just has two wheels on one axis. The operator uses the digging arm to drag the machine forward on the two wheels.

These little tools were perfect for minor work and confined areas. They were particularly cost-effective since they could walk on their own or be pulled behind another piece of equipment for longer trips. Richard Smalley made this tool in 1959.

The YANMAR YNB300 Mini Excavator

In 1968, Yanmar made the first compact excavator that could move itself using diesel power. The firm started in Osaka, Japan, in 1912 and specializes in diesel engines. It also develops heavy machinery and fishing gear. Yanmar focused on making the world’s smallest diesel engine in 1933. This development most likely resulted in the creation of a smaller, more compact version of the excavator.

The Mini Excavator: FAQ

Can a mini excavator clear tree stumps?

You may use a tiny excavator to get rid of tree stumps. A small excavator may be a fantastic tool for many projects if you use the proper size and accessories.

What is the difference between a mini excavator and a backhoe?

A backhoe has a digger on the back and loaders or other equipment on the front. A micro excavator is a miniature excavator that only has one digging arm on the front.

The operator seat in a backhoe cab can turn 180 degrees, so the operator may use the machine from either the front or the back of the tractor. A backhoe can do a lot of things, such dig, lift, move, grade, and more.

A tiny excavator has one arm and a bucket or other attachment on the end. The whole cab turns, and it’s usually utilized for digging.