9 Best Practices for Maintenance of Large Scale Industrial Machines

If there is one universal truth in the world of heavy industry, construction, and manufacturing, it is this: Iron doesn’t forgive neglect.

Whether you are managing a fleet of excavators tearing up earth for a new skyscraper or overseeing a line of industrial loaders in a high-intensity quarry, your machinery is the absolute lifeblood of your operation. When the engine hums, revenue flows. When a breakdown occurs on the job site, the cash flow ceases, yet the overhead expenses such as wages, insurance, and meeting deadlines continue.

Maintaining large-scale industrial machines is no longer just about fixing what breaks. That is a strategy for the past. Today, successful fleet management is about asset health management. It’s about a proactive, almost clinical approach to ensuring that every piston, pin, and hydraulic hose is operating at peak efficiency.

This guide goes beyond the basic “change your oil” advice. We are going deep into the best practices for industrial machine maintenance, covering the strategies, the specific checkpoints, and the human elements that define the difference between a profitable project and a money pit.

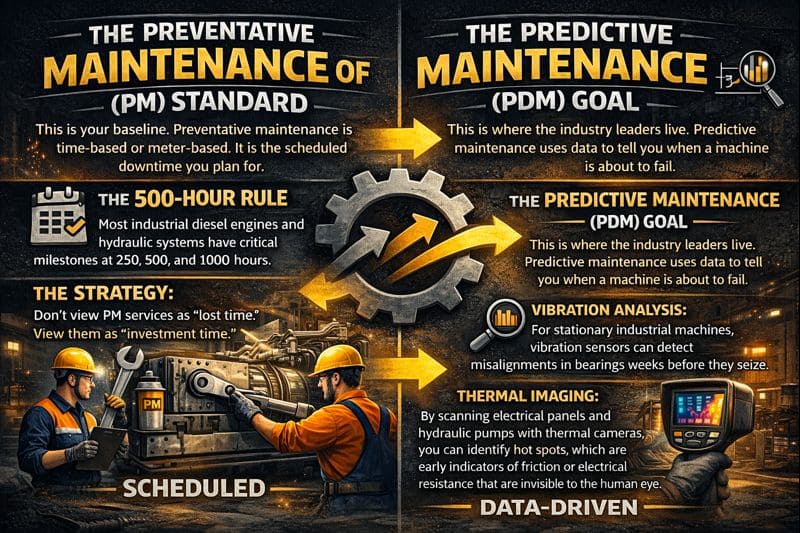

1. The Strategic Shift: From Reactive to Predictive Maintenance

The biggest mistake fleet managers make is relying on reactive maintenance (also known as run-to-failure). This is the practice of running a machine until a component fails and then scrambling to fix it. While this procedure maximizes the lifespan of the part, it wreaks havoc on your schedule.

To truly optimize your operation, you must move up the ladder of maintenance maturity:

The Preventative Maintenance (PM) Standard

This is your baseline. Preventative maintenance is time-based or meter-based. It is the scheduled downtime you plan for.

-

The 500-Hour Rule: Most industrial diesel engines and hydraulic systems have critical milestones at 250, 500, and 1000 hours.

-

The Strategy: Don’t view PM services as “lost time.” View them as “investment time.” A planned 4-hour shut down for a full service on a Tuesday afternoon is infinitely cheaper than an unplanned 4-day shutdown in the middle of a Friday rush because a neglected filter collapsed.

The Predictive Maintenance (PdM) Goal

This is where the industry leaders live. Predictive maintenance uses data to tell you when a machine is about to fail.

-

Vibration Analysis: For stationary industrial machines, vibration sensors can detect misalignments in bearings weeks before they seize.

-

Thermal Imaging: By scanning electrical panels and hydraulic pumps with thermal cameras, you can identify hot spots, which are early indicators of friction or electrical resistance that are invisible to the human eye.

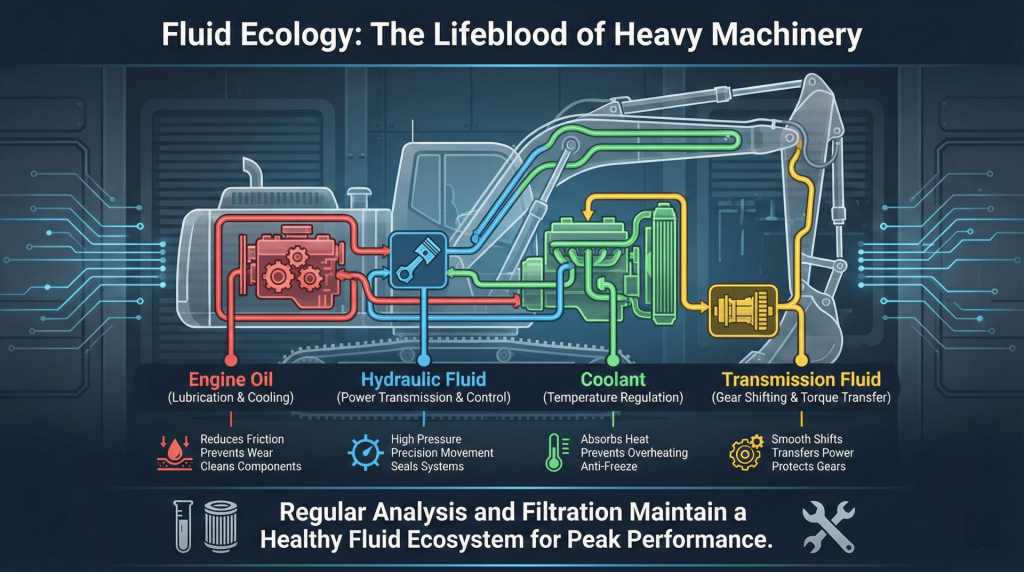

2. Fluid Ecology: The Lifeblood of Heavy Machinery

If the steel frame is the skeleton of your machine, the fluids are its blood. Contaminated fluid is responsible for a staggering percentage of hydraulic and engine failures.

The Art of Oil Analysis

Changing oil is good; analyzing it is better. Regularly sending oil samples to a lab is like getting blood work done at the doctor. It tells you exactly what is happening inside the engine without taking it apart.

-

High Silicon levels? You have a dirt ingress issue (likely a bad air filter).

-

High Copper or Lead? Your bearings are wearing out.

-

Fuel Dilution? You might have a leaking injector or piston ring issues.

Hydraulic Hygiene

Hydraulic systems in modern large-scale machines operate at incredibly high pressures (often exceeding 3,000 PSI). At these pressures, microscopic dust particles act like sandblasting grit, eating away at valves and pumps from the inside out.

-

The Rule of Thumb: Never leave a hydraulic system open to the air longer than necessary.

-

The Fill Procedure: Always filter new oil before putting it into the machine. Surprisingly, new oil from a drum is often not clean enough for high-precision modern hydraulic systems. Use a filter cart when topping up.

Coolant Conditioning

Neglected coolant causes cavitation—a phenomenon where tiny bubbles implode against cylinder liners, pitting the metal until it fails.

-

Check the pH: Coolant can become acidic over time, eating away at seals and gaskets. Use test strips weekly to monitor acidity and freezing points.

3. The Daily Walk-Around: Weaponizing the Operator’s Eye

You can employ the best mechanics in the world, but they aren’t in the cab for 10 hours a day. Your operators are your first line of defense. However, a generic check the machine instruction rarely works. You need a structured, militaristic routine.

The Pre-Start Circle

Before the key turns, the operator must walk the circle of safety.

-

Tires and Tracks: Look for deep cuts, embedded rocks, or uneven wear patterns. On tracked machines (like excavators or track loaders), check the tension. A loose track can de-track on a slope; a tight track wears out the undercarriage prematurely.

-

Hoses and Lines: Look for the weep. A hydraulic hose rarely bursts without warning. It usually starts with a weep—a damp spot on the rubber where fluid is sweating through. Catching a weep today saves 50 gallons of spilled oil tomorrow.

-

The Ground Test: Look under the machine. Puddles tells the truth. If there is fresh oil on the ground, the machine does not move until the source is found.

The Warm-Up Protocol

Industrial machines are massive thermal systems. They need to expand evenly.

-

Idle Time: Allow the engine to idle for 5 minutes. This gets oil pressure up and lubricates the turbochargers before they spin up to high RPMs.

-

Hydraulic Cycling: In cold weather, cycle the boom and bucket slowly without a load. This pushes warm fluid through the cylinders, preventing thermal shock to the seals.

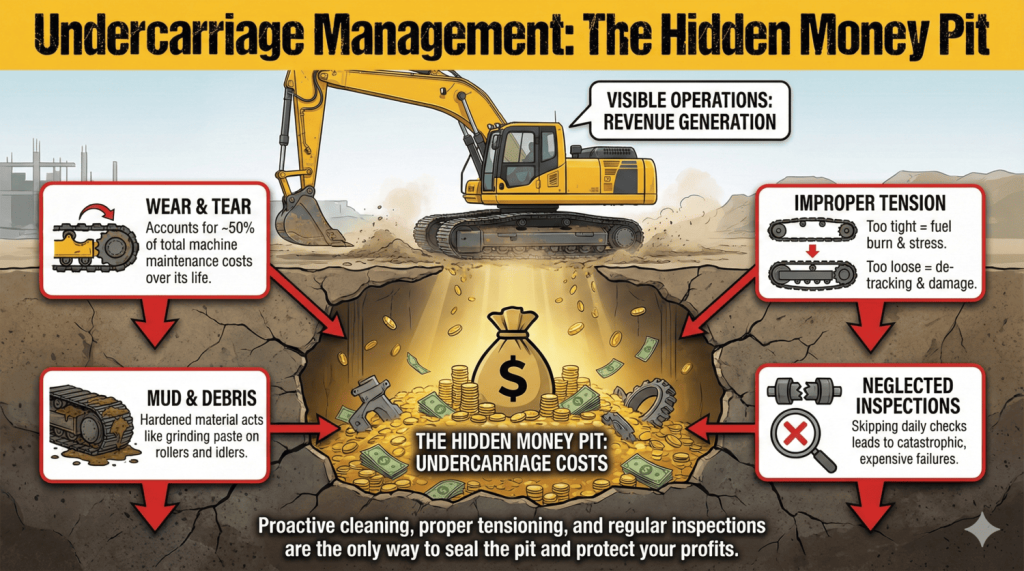

4. Undercarriage Management: The Hidden Money Pit

For tracked machinery like bulldozers and mini excavators, the undercarriage can represent 50% of your total maintenance costs over the life of the machine. It is the most expensive component to replace, yet it takes the most abuse.

Cleaning is Maintenance

Mud is the enemy. When mud dries on the tracks, it hardens like concrete. This packs into the sprockets and rollers, increasing tension and grinding away the metal.

-

The End-of-Day Rule: Shoveling out the tracks at the end of every shift is mandatory. It takes 10 minutes but saves thousands of dollars in roller wear.

Tension Matters

Track tension is not set it and forget it. It changes based on the terrain.

-

Mud/Sand: You generally want slightly looser tracks to allow material to escape.

-

Rock/Hard Ground: You want tighter tension to prevent the track from slipping off the rollers.

-

The Measurement: Teach your crew how to measure track sag properly. A track that is too tight increases load on the final drive motor, burning fuel and reducing power.

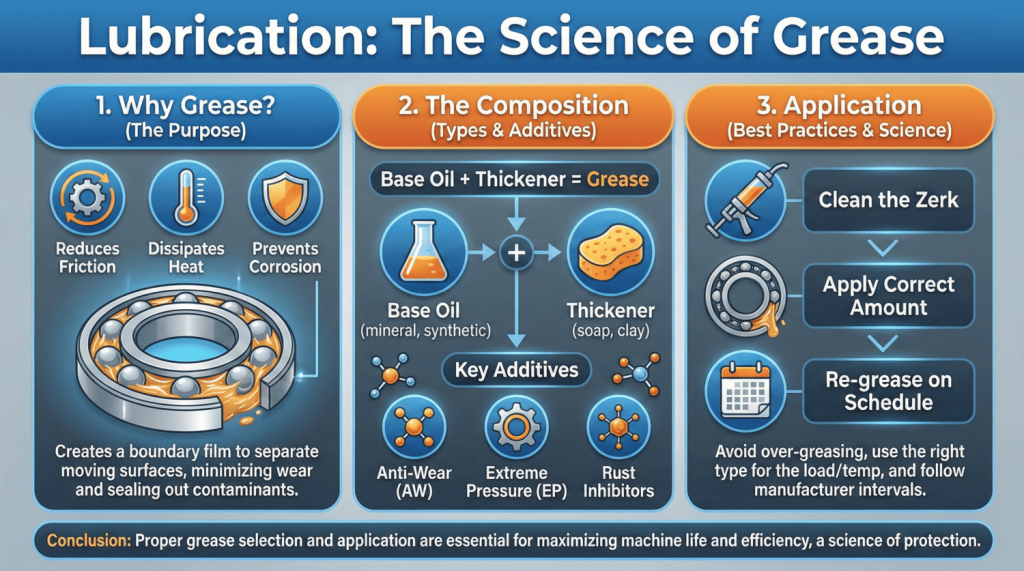

5. Lubrication: The Science of Grease

Greasing is often delegated to the lowest-paid person on the site, but it is a critical scientific process.

Not All Grease is Created Equal

Using a generic red grease for everything is a recipe for failure.

-

High Temp vs. High Load: Pins on a bucket hinge experience extreme pressure (shock loading), requiring a grease with molybdenum disulfide (moly grease) that stays in place under crushing weight. High-speed bearings (like on a conveyor) need a lithium complex grease that creates a low-friction film.

The Clean Zerk Philosophy

The grease nipple (zerk) is the gateway to the bearing. If the zerk is covered in old dirt and you attach the grease gun, you are hydraulically injecting sand directly into the joint.

-

Best Practice: Wipe every zerk with a rag before attaching the gun. If a zerk is blocked, replace it immediately—do not skip it. A skipped grease point is a future seized pin.

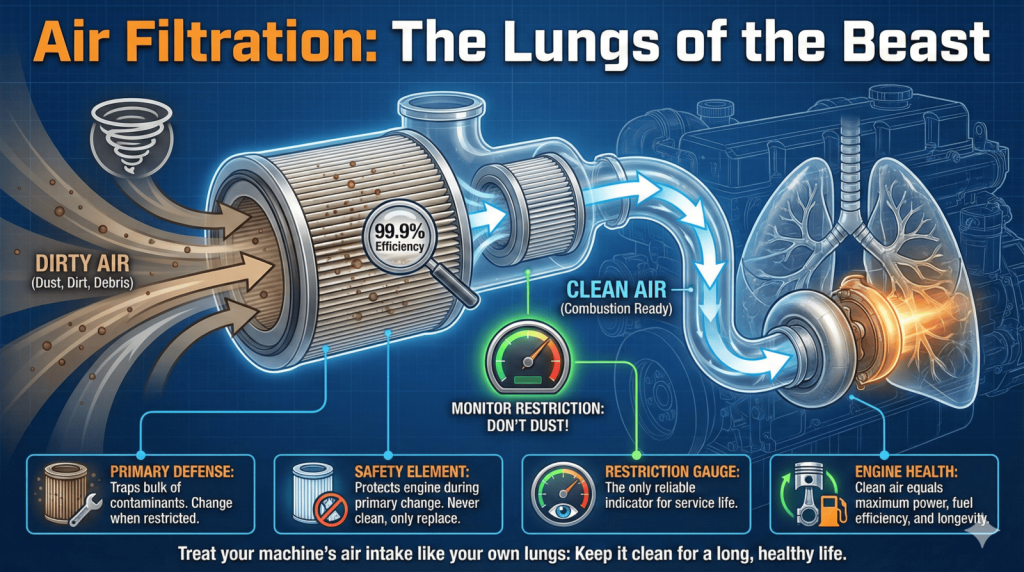

6. Air Filtration: The Lungs of the Beast

Industrial sites are dusty. Whether it’s silica dust, sawdust, or general construction debris, the air is hostile.

The Dusting Myth

A common harmful habit among old-school operators is pulling out the air filter and banging it against a tire to clean it.

-

Stop Doing This: Banging a filter damages the paper media, creating microscopic tears that let dust bypass the filter and enter the engine. Once dust enters the combustion chamber, it acts like sandpaper on the cylinder walls.

-

The Solution: Use a filter restriction indicator (the little gauge on the air cleaner housing). Only change the filter when the gauge says so. Over-servicing air filters actually increases the risk of dusting the engine because every time you break the seal, you risk letting dirt in.

7. Documentation and Digital Twins

In the modern era, if it isn’t written down, it didn’t happen. Keeping a service log is vital for three reasons:

-

Warranty Compliance: Manufacturers will deny warranty claims if you cannot prove maintenance was done.

-

Resale Value: A machine with a documented birth-to-present service history sells for significantly more at auction than a machine with zero paperwork.

-

Pattern Recognition: Logs help you spot lemons. If Machine A blows a hydraulic hose every 3 months and Machine B never does, you have a systemic issue with Machine A (or the operator driving it).

Telematics Integration: Most modern large-scale machines come with telematics (GPS and onboard diagnostics). Use this data. Set up alerts for High Water Temperature or Low Oil Pressure. This allows you to call the operator and shut them down before the engine blows.

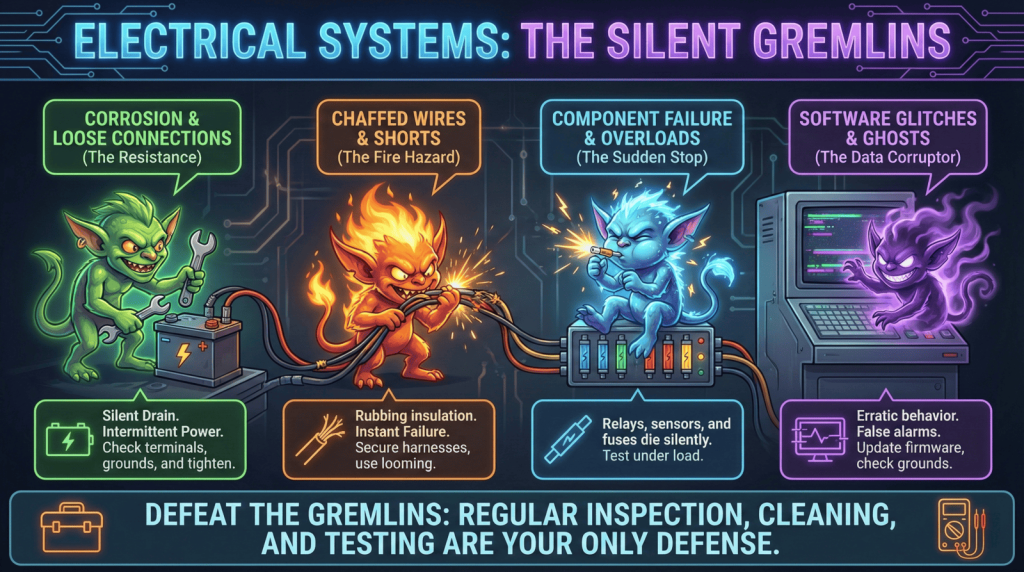

8. Electrical Systems: The Silent Gremlins

As machines become more computerized, electrical maintenance becomes just as important as mechanical maintenance.

Battery Hygiene

Vibration kills batteries. Ensure battery hold-downs are tight. A bouncing battery causes internal plate damage.

-

Corrosion Check: Green/white corrosion on terminals creates resistance, forcing the alternator to work harder. Clean terminals with hot water and baking soda, and seal them with a dielectric spray.

Wiring Harnesses

Inspect wiring harnesses for rubbing. A wire rubbing against a hydraulic line is a fire hazard. Use zip ties and protective looming to secure loose wires.

9. Training the Human Element

Ultimately, maintenance is a human behavior issue. You must build a culture where taking care of the gear is respected.

-

Incentivize Care: Consider implementing a Cleanest Cab bonus or a Best Inspection Report award.

-

Listen to Operators: When an operator says, It feels a bit sluggish today,” listen to them. They know the machine’s personality better than anyone.

Conclusion: Reliability is a Choice

Maintaining large-scale industrial machines is a relentless pursuit of excellence. It requires a blend of disciplined scheduling, scientific fluid analysis, and a culture of ownership among your crew. By shifting from reactive repairs to proactive asset health management, you ensure that your projects stay on track, your profit margins stay healthy, and your machines stay in the dirt where they belong.

When you invest in maintenance, you aren’t just buying oil and filters; you are buying uptime. You are buying the confidence to bid on bigger jobs, knowing your fleet can handle the pressure.

The Right Partner for the Job: Typhon Machinery

Of course, the most effective maintenance program starts with choosing the right equipment. You want machines that are engineered for accessibility, durability, and ease of service. You need equipment that respects the mechanic as much as the operator.

This is where Typhon Machinery excels.

In an industry often crowded with over-complicated designs, Typhon Machinery has carved out a reputation for building Mechanic-Friendly heavy equipment. From their rugged mini excavators to their versatile skid steer loaders, every Typhon machine is designed with maintenance in mind.

-

Easy Access Points: Engine compartments that open wide, placing filters and dipsticks within easy reach.

-

Simplified Hydraulics: Robust hose routing that minimizes rubbing and allows for quick field replacements.

-

Heavy-Duty Undercarriages: Built with high-tensile steel to withstand the harshest environments with longer wear cycles.

When you choose Typhon Machinery, you aren’t just buying a machine; you are buying a partner in productivity. Their equipment is built to run longer, work harder, and require less downtime, ensuring that your maintenance team spends less time fixing and your operators spend more time earning.

Don’t let downtime define your business. Equip your fleet with the reliability of Typhon Machinery.