Introduction to Kubota Engines for Mini Excavators

Why Kubota Dominates the Compact Equipment Market

For a long time, people have trusted Kubota when it comes to small construction tools. Kubota makes the diesel engines that many micro excavators across the world utilize. These engines are known for being very efficient, dependable, and strong. Their engines power some of the toughest machinery that do work every day in construction, landscaping, farming, and maintaining infrastructure. But what makes Kubota different from the others?

First of all, they are committed to compact power. Kubota is different from other companies because they design their engines from the ground up to be used in small machines, rather than starting with larger engine blocks and working their way down. This focus ensures that even the smallest models boast high torque, minimal fuel consumption, and exceptional dependability.

Original equipment manufacturers (OEMs) commonly use Kubota engines because they are easy to integrate, last a long time, and don’t need much maintenance. Kubota is the leader in the micro excavator market because its machines are both powerful and useful. This is especially true on job sites where space, mobility, and weight are important.

Importance of Engine Choice in Mini Excavators

It’s not only about getting the biggest or most powerful engine for a compact excavator. It’s important to match the engine to the job. The engine is essential whether you are trenching, grading, or lifting. It powers everything, from the blade to the hydraulic system to the travel motors.

When an engine doesn’t have enough power, it will have trouble with heavy loads, which can cause wasteful cycles, overheating, and premature wear. But an overly powerful engine may waste gas, raise ownership costs, and run poorly if not properly matched with the rest of the system.

This is where comparing the D902, D722, and Z482 becomes quite helpful. Knowing the distinctions between engines helps contractors, fleet managers, and even people who want to fix up their homes make wise, cost-effective choices. Whether you’re replacing an old engine or looking for a new one, it’s the most important part of your investment. And it better be the correct one.

Overview of Kubota Engine Models

General Specs and Use-Cases of D902

The Kubota D902 engine is a three-cylinder, liquid-cooled diesel engine known for its powerful performance and compact size. It has a peak power of approximately 24.8 HP at 3600 RPM with a displacement of 0.898 liters (898 cc). It belongs to the Super Mini Series of Kubota and, as such, can be found in various mini excavators, utility vehicles, and other compact industrial equipment.

The D902 engine excels in more demanding hydraulic applications. Through its torque curve and quick response time, it can easily handle increased grunt for excavating, leveling, and running hydraulic attachments. In addition to those amazing features, the D902, with zero compliance to EPA Tier 4 and EU Stage V norms, doesn’t cost the environment at all.

The D902 primarily caters to medium-sized mini excavators under fuel-saving restrictions without compromising performance. The engine is not only of low weight, but also it is very smooth, and it is the reason many machine builders prefer it for the best power-to-weight ratio. Most rental services keep picking the D902 for the major reasons of less frequent breakdowns, thus less maintenance and lower costs.

The D722 engine is Explained and Defined as “Small but Terrible” by Kubota

Basically, the Kubota D722, another of the manufacturer’s products, is a three-cylinder, liquid-cooled diesel engine but of smaller dimensions compared to the D902, with a displacement of 0.719 liters (719 cc). Measuring 18 HP at 3600 RPM, this compact machine doesn’t fool around. This engine is notably silent and fuel-efficient, making it suitable for urban or indoor use because of its low noise and emissions.

The D722 is the engine of choice in ultra-compact mini excavators and micro diggers. They are the most appropriate machines for trenching, foundation prep, and other precision applications in confined areas. The compact model and the lower power output of the machine help reduce the overall machine weight, which is crucial for transportation and mobility.

The engine excels in light-duty digging, precision work, and cost-effectiveness. This engine is also a popular replacement choice for many users because it can fit into older models and has readily available spare parts.

Z482: Small Yet Mighty for Tight Applications

If you could say that a certain engine is “small yet mighty,” its name would be the Kubota Z482 engine. It has been equipped with a two-cylinder, liquid-cooled diesel motor and can produce 13 HP at 3600 RPM from 0.479 liters (479cc). Such an engine is not as such designed for micro-excavation machinery and equipment, but it is just that this has the advantage of being able to reach the most restricted places (even those of residential gardens, basements, or narrow alleys).

The peculiar feature of Z482’s compact size makes it very sought-after by those OEMs who want to have greater design flexibility. This engine is very economical in fuel and silently consumes, even when operating at full capacity, and is therefore appropriate for situations where inappropriate noise should be avoided, such as hospitals or schools.

Although it may be the case that the engine has no application in heavy-duty excavation, it certainly can be found in light-duty excavation and utility tasks. The engine typically finds its use in trenchers on wheels, compact power units, and other similar machines. It is a user-engine because of the minimum level of vibration.

In-Depth Comparison of Engine Specifications

Horsepower and Torque Analysis

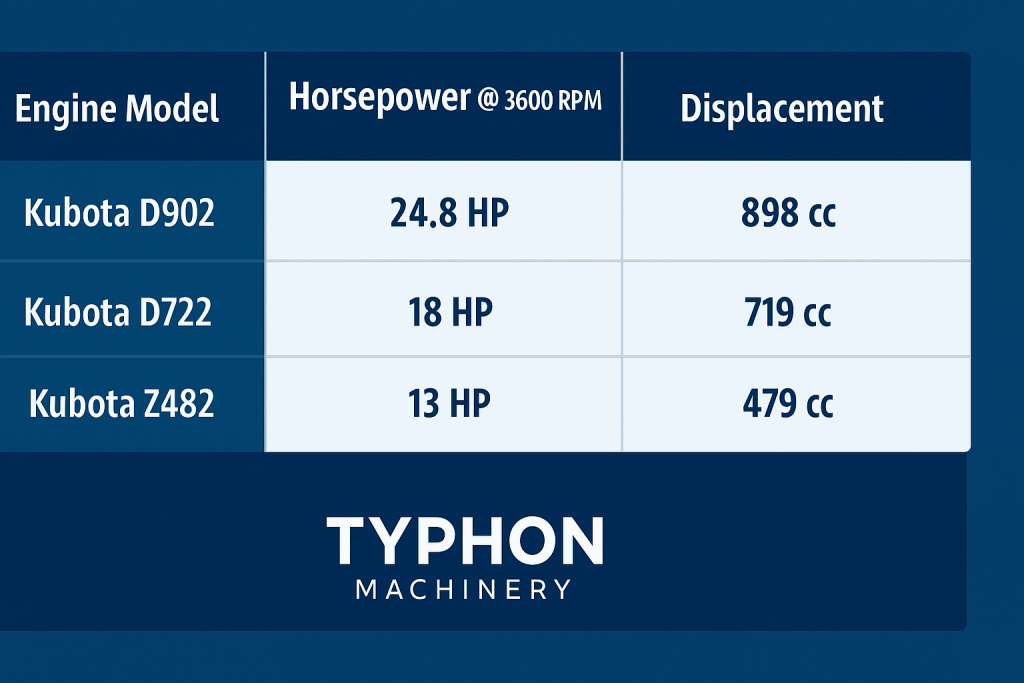

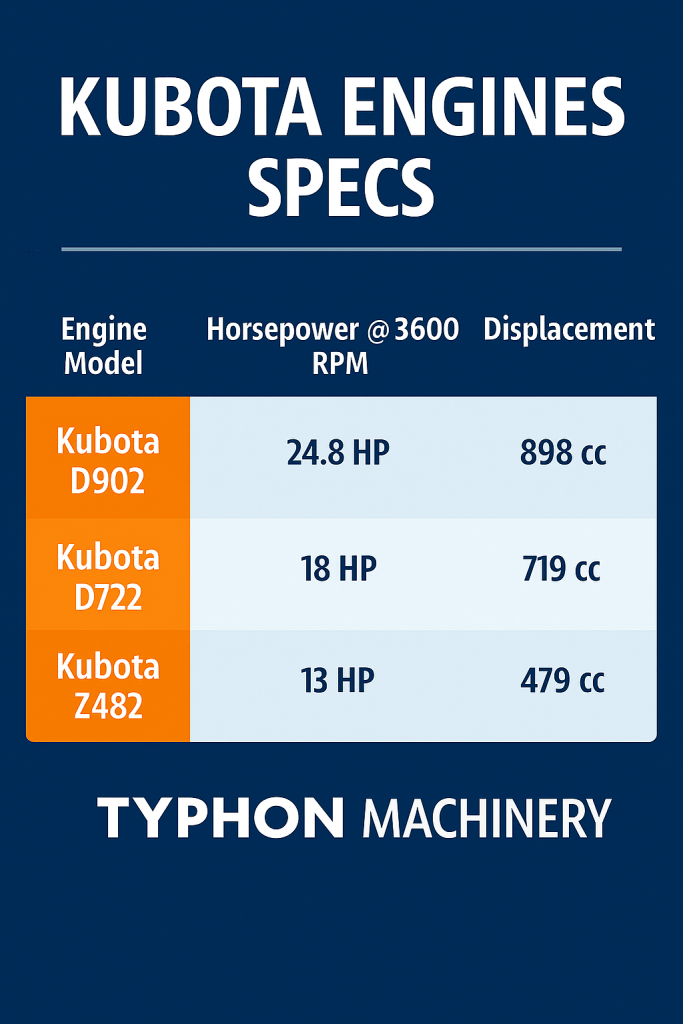

Horsepower and torque are the bread and butter of any diesel engine comparison. Let’s break them down side-by-side:

| Engine Model | Horsepower @ 3600 RPM | Torque (Nm) | Displacement |

| Kubota D902 | 24.8 HP | ~56.6 Nm | 898 cc |

| Kubota D722 | 18 HP | ~43.2 Nm | 719 cc |

| Kubota Z482 | 13 HP | ~31.7 Nm | 479 cc |

As expected, the D902 leads the pack in both horsepower and torque, making it suitable for heavier mini excavator applications. The D722 offers a balance between compact size and usable power, while the Z482 is focused on light-duty use, excelling in environments where minimal disruption and compactness are key.

Torque matters more than horsepower in digging applications, and the D902’s superior torque output allows better hydraulic response, faster cycle times, and smoother operations with attachments.

Performance in Real-World Applications

Fuel Efficiency Under Load

Fuel efficiency is a major concern for anyone operating a mini excavator, whether it’s a large contractor managing a fleet or a small business owner looking to control operational costs. The difference between these three Kubota engines—D902, D722, and Z482—can add up significantly over time, especially when machines are used daily.

The Z482, with its two-cylinder configuration, leads the group in raw fuel efficiency. Its smaller displacement and lighter weight translate to lower fuel consumption, especially in light-duty operations. In scenarios where machines idle or operate at partial loads for extended periods—like landscaping or fence installations—the Z482 proves to be highly economical.

On the other hand, the D722 strikes a balance between efficiency and output. It offers better fuel economy than the D902 under medium workloads but provides more power than the Z482. It’s best suited for users who demand moderate performance without sacrificing economy.

The D902, while consuming more fuel, makes up for it with its power output. Under heavy loads and high RPM use, such as digging through clay or operating multiple attachments, the extra fuel translates directly into better productivity. For applications where downtime costs more than diesel, the D902 is the smart choice.

Power Delivery and Operational Smoothness

Operational smoothness directly affects the operator’s experience and the machine’s overall efficiency. Engines that deliver power with less vibration and noise reduce fatigue and increase job site safety.

The D902, with its three-cylinder layout and advanced balancing, offers the smoothest power delivery of the three. It performs well at low RPM and handles load changes with minimal hesitation. Whether it’s digging, swinging, or moving across uneven terrain, the D902 remains stable.

The D722 also features a three-cylinder setup, and while slightly less powerful, it offers very respectable smoothness in power delivery. It’s responsive, quick to recover under load, and suitable for most general excavation tasks.

Meanwhile, the Z482, being a two-cylinder engine, naturally experiences more vibration. That said, Kubota’s engineering minimizes this through smart mounting and counterbalancing. For low-impact, light-duty work, the roughness isn’t a deal-breaker—but for prolonged use or precision jobs, it can be noticeable.

Reliability in Harsh Environments

All three engines are built with durability in mind, but their design and power capabilities determine how well they fare in tough conditions. The D902, with its higher displacement and robust build, is often the go-to for extreme temperatures and heavy-duty work. Its performance doesn’t falter even in high-dust or uneven terrain, making it ideal for construction sites.

The D722 performs well in standard jobsite conditions. It holds up under dust, moisture, and temperature variations and features corrosion-resistant materials that add to its longevity. It’s a dependable engine for urban contractors and small equipment rental firms.

The Z482 is better suited for controlled environments. While reliable in its own right, it’s not engineered for extreme duty cycles. It works best in light-duty machines, such as backyard excavation or interior demolition, where harsh environmental challenges are minimal.

Size and Weight Considerations

Installation Space and Chassis Fit

One of the most defining factors in engine selection is its physical size and how well it integrates with the mini excavator chassis. Space inside compact machines is limited, and any gain or loss in size can impact not just engine placement, but also cooling, maintenance access, and machine balance.

The Z482 is the smallest and lightest of the trio, making it ideal for extremely compact machines. Its size allows for greater design flexibility, whether you’re retrofitting or creating a custom build. It’s perfect for narrow-body machines used in interior renovations or confined residential jobs.

The D722 occupies slightly more space but remains compact enough to fit a wide range of mini excavators without issue. It provides more power without drastically increasing the machine’s footprint, which is why it’s a common engine in the sub-2-ton class.

The D902, being the largest of the three, requires a bit more room. That said, it’s still compact by diesel engine standards and fits comfortably into mid-size mini excavators. It’s a good choice for applications where more digging force is needed, and the machine can accommodate a slightly larger engine bay.

Transport and Maneuverability Implications

Machine weight influences transport logistics, fuel consumption, and job site maneuverability. A lighter engine can reduce the overall equipment weight, which is critical for trailer transport and navigating fragile terrain.

The Z482 significantly reduces machine weight, making mini excavators more trailer-friendly and less likely to damage delicate surfaces like gardens or tiled floors. It also enhances agility—an advantage in tight urban spaces.

The D722 strikes a middle ground. It supports a stable machine that’s light enough to maneuver easily but heavy enough for traction and digging performance. For most users, it offers the best balance between transportability and performance.

The D902, while the heaviest, provides the weight needed for stable operations during heavy lifting or trenching. Its higher mass enhances downforce and traction, especially when operating on uneven or muddy terrain. If your machine will regularly handle larger buckets or hydraulic attachments, this added weight is an asset, not a drawback.

Maintenance and Longevity

Service Intervals and Common Repairs

When it comes to mini excavators, downtime is money lost. That’s why it’s essential to consider how often your engine needs servicing and how easy it is to get back to work.

All three Kubota engines boast long service intervals, with routine oil changes and filter replacements typically required every 100–200 hours, depending on usage. However, the D902, being designed for heavier use, tends to have more robust components that withstand longer run times between major servicing.

The D722 shares many of the D902’s design philosophies but at a smaller scale. It’s less stressed under operation, which often translates to fewer unexpected repairs. For standard applications, it provides a nice balance between uptime and low service costs.

The Z482, while simpler in design, may require more frequent attention due to its two-cylinder configuration. Fewer moving parts can be an advantage, but they tend to wear out quicker under constant load. It’s best suited for intermittent use or low-hour operations.

Availability of Parts and Service Networks

Kubota engines are globally recognized, and their parts are widely available. Whether you’re in the U.S., Europe, or Asia, you can find authorized dealers and third-party suppliers that stock genuine or aftermarket parts for these engines.

Among the three, the D902 has the widest support network, being the most commonly used engine in newer equipment. Service manuals, replacement parts, and even rebuilt engines are readily available.

The D722 also enjoys broad availability, especially in the used equipment and small contractor markets. It’s easy to service, and many technicians are familiar with it.

The Z482, while slightly less common, still benefits from Kubota’s global reach. It’s relatively simple to work on, and parts can be sourced without much hassle.

Expected Lifespan and Durability Factors

Kubota engines are known to run well beyond 5,000 to 7,000 hours with proper maintenance. Of the three, the D902 often has the longest lifespan under heavy-duty conditions. It’s built for endurance and can take on longer cycles with fewer breakdowns.

The D722 typically lasts around 4,000 to 6,000 hours, especially when operated within its intended capacity. It’s not uncommon to see these engines in second-hand excavators still going strong.

The Z482, while durable, is more sensitive to prolonged heavy use. Its lifespan is closer to 3,000 to 5,000 hours, making it ideal for part-time operators or lighter duty fleets.

Cost Efficiency and Total Cost of Ownership

Purchase Price vs Long-Term Value

When evaluating engines, the upfront price often catches the most attention—but the real value comes from long-term performance, maintenance, and operational efficiency. Let’s compare.

The Z482 is typically the least expensive of the three engines. It’s an economical option both in purchase and in integration into compact machines. This makes it attractive for hobbyists, small contractors, and fleet managers looking to reduce capital expenditures. However, the trade-off is a lower performance ceiling and a shorter lifespan under demanding use.

The D722 lands in the mid-price range. Its cost reflects its more robust capabilities and longer service life. For users who want a mix of affordability and utility, the D722 hits the sweet spot. You get a dependable workhorse that doesn’t burn through your budget upfront or over time.

The D902 commands the highest initial price, but with that comes unmatched performance, longer lifespan, and reduced downtime. Its strong resale value also plays into the equation, often making it the best investment for commercial applications where performance and uptime are critical.

Operating Costs and Fuel Consumption

Fuel efficiency, oil changes, filter replacements, and wear-and-tear costs all factor into the total cost of ownership (TCO). Here’s how each engine stacks up:

- Z482: Lowest fuel consumption but can be costlier in the long run due to more frequent service under stress.

- D722: Excellent fuel efficiency with moderate operational costs. Best suited for users balancing budget and daily use.

- D902: Higher fuel use, but also less downtime, fewer repairs under load, and better ROI when used for power-intensive work.

Resale Value Insights

The Kubota name itself holds resale value. That said, the D902 has the strongest resale performance due to its demand in newer machines and applications. Buyers are often willing to pay more for a used engine with solid service records.

The D722 is next in line, holding its value well among small contractors and in the used equipment market.

The Z482, while not as sought-after in resale, still has value—particularly in specific niches like ultra-compact trenchers, landscaping machines, and portable equipment.

Noise Levels and Environmental Impact

Decibel Ratings and Worksite Comfort

Noise level is a big factor—especially on urban, residential, or indoor job sites. The quieter the engine, the easier it is to meet noise regulations and keep neighbors and workers happy.

- Z482: Among the quietest in the lineup due to its two-cylinder design and small size. Operates under 70 dB in many setups.

- D722: Also very quiet, and thanks to its balanced three-cylinder build, it operates smoothly and without harsh noise spikes.

- D902: Slightly louder due to higher output but still relatively quiet compared to competitors. Ideal for outdoor use or larger sites where sound isn’t a limiting factor.

Compliance with Environmental Standards

All three engines meet EPA Tier 4 and EU Stage V standards, making them suitable for modern regulatory environments. Kubota has done an excellent job of integrating after-treatment technologies like diesel oxidation catalysts (DOCs) and exhaust gas recirculation (EGR) to ensure compliance without compromising performance.

The Z482 and D722 are often preferred for indoor or emissions-sensitive environments due to their ultra-low emissions profiles.

Suitability for Different Excavator Models

Best Fits for Residential Use

For residential contractors, landscapers, and DIYers, the engine needs to be quiet, fuel-efficient, and easy to transport.

- Z482: Best for micro excavators in landscaping, pool installations, and small backyard projects. Quiet, compact, and cost-effective.

- D722: Great for light-to-medium-duty jobs that need a bit more power without losing the advantages of a compact size.

- D902: Suitable for larger residential jobs involving retaining walls, deep trenching, or moving large amounts of earth quickly.

Ideal Models for Commercial and Industrial Use

For commercial operators, power and durability become more important.

- D902: Best option here. It thrives under heavy-duty cycles, works well with attachments, and offers the best reliability and resale.

- D722: Works for medium-duty applications, maintenance work, and light trenching.

- Z482: Generally not recommended for heavy commercial use unless the job requires minimal digging and ultra-compact gear.

User Feedback and Industry Reputation

Insights from Operators and Dealers

Operators and dealers universally respect Kubota for its reliability and easy maintenance. Here’s what they often say:

- D902: “Powerful and bulletproof.” Operators appreciate its responsiveness and ability to power through demanding conditions. Dealers love its high resale value and low return rate.

- D722: “Dependable and efficient.” Many contractors report thousands of hours of use with minimal issues. It’s considered the perfect all-rounder.

- Z482: “Surprisingly capable for its size.” It’s praised for ultra-low fuel use and quiet operation. The best feedback comes from landscapers and interior demo specialists.

Manufacturer Support and Warranty Reviews

Kubota offers strong manufacturer support, with extensive dealer networks, training, and customer service. Engines typically come with standard warranties ranging from 2,000 to 3,000 hours or 2–3 years, whichever comes first.

Parts availability is excellent, and service centers can be found almost anywhere. This makes ownership less stressful and maximizes uptime.

Pros and Cons Breakdown of Each Engine

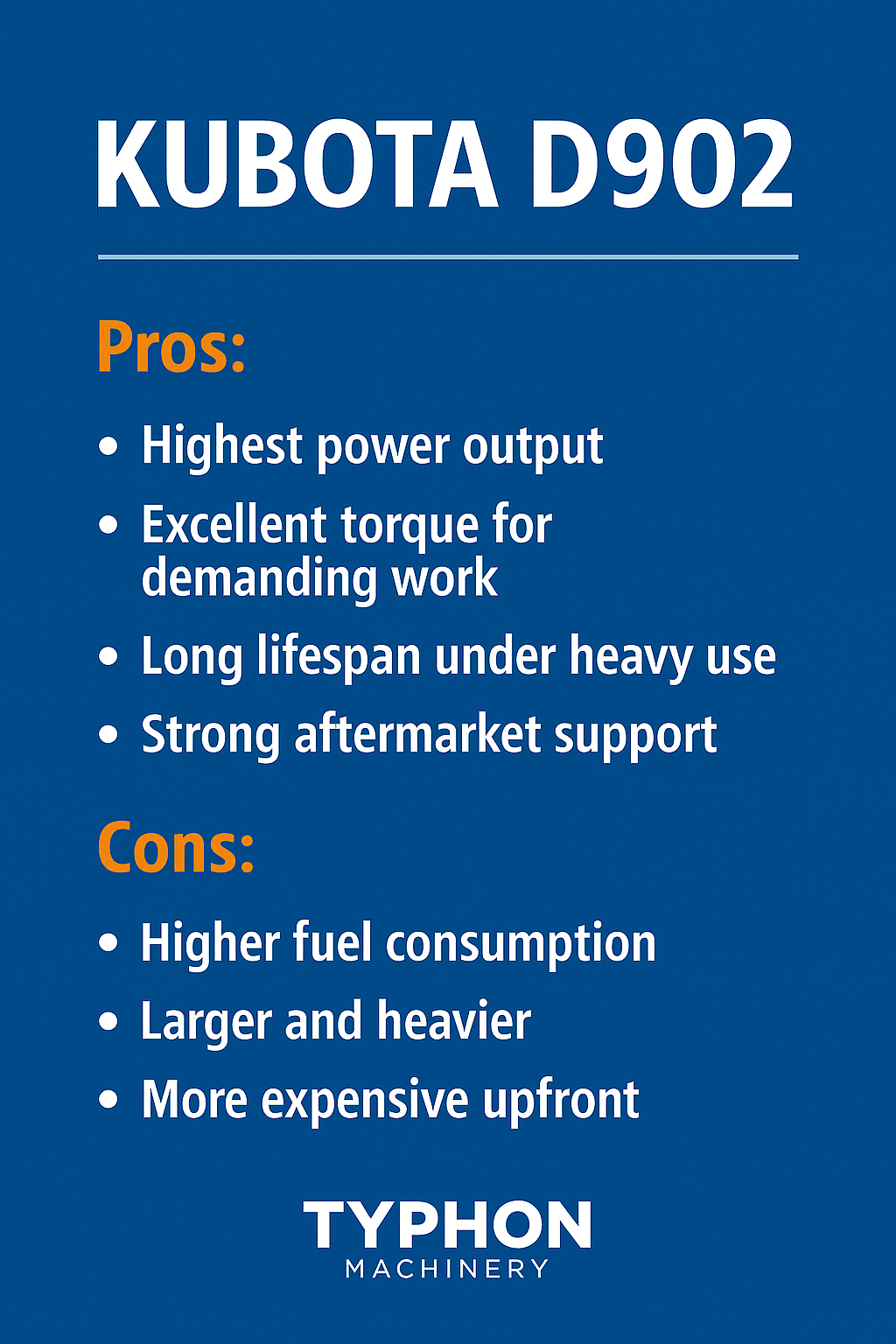

Kubota D902

Pros:

- Highest power output

- Excellent torque for demanding work

- Long lifespan under heavy use

- Strong aftermarket support

Cons:

- Higher fuel consumption

- Larger and heavier

- More expensive upfront

Kubota D722

Pros:

- Balanced power and efficiency

- Compact and quiet

- Very reliable in medium-duty tasks

- Broad compatibility with machines

Cons:

- Slightly less powerful for high-impact digging

- Moderate cost

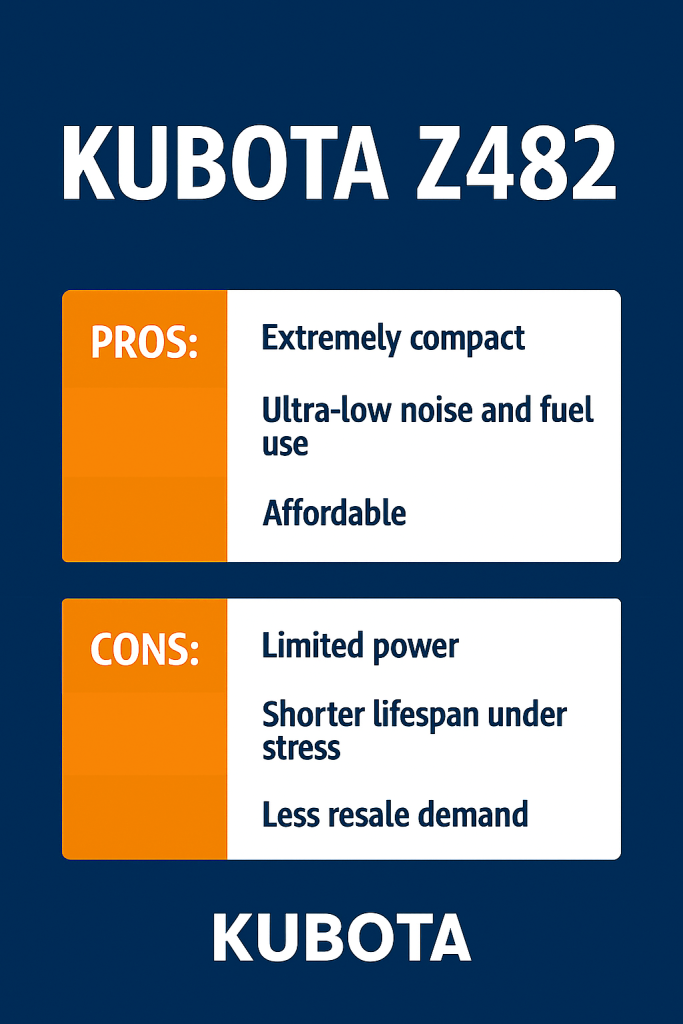

Kubota Z482

Pros:

- Extremely compact

- Ultra-low noise and fuel use

- Affordable

- Great for indoor or sensitive zones

Cons:

- Limited power

- Shorter lifespan under stress

- Less resale demand

How to Choose the Right Engine for Your Mini Excavator

Key Considerations Based on Use Case

When selecting the right Kubota engine—D902, D722, or Z482—for your mini excavator, you need to focus on your core application. Every job site, operator, and machine setup has different needs. Let’s break down the decision-making process into actionable points:

- Job Type: For high-performance digging, trenching, and attachments like augers or breakers, the D902 is the most suitable. For smaller landscaping and municipal work, the D722 provides enough power while staying fuel-efficient. The Z482 is perfect for tight spaces and jobs where weight and quiet operation matter more than digging depth.

- Machine Size: If your excavator is a compact model under 1.5 tons, the Z482 or D722 will fit better due to their smaller size and weight. Mid-size mini excavators (1.5 to 2.5 tons) benefit from the D902’s torque.

- Budget: On a tight budget? The Z482 offers the lowest entry cost. The D722 offers a great mix of affordability and performance, while the D902 requires more initial investment but pays off in heavy use.

- Usage Frequency: If you’re running your machine every day, the D902 provides better ROI. For occasional or weekend use, the Z482 will keep costs low.

- Transport & Accessibility: If you need to tow your mini excavator often or work in basements, backyards, or rooftops, the lightweight Z482 becomes the practical choice.

Expert Tips for Optimal Selection

- Don’t Oversize: Bigger isn’t always better. If you don’t need the power, you’ll just spend more on fuel and maintenance.

- Look at Total Ownership Cost: Factor in fuel use, parts, servicing, and downtime. Sometimes the mid-priced engine ends up saving you more.

- Think Ahead: Consider future jobs and attachments. Will you be running a thumb, tilt bucket, or auger? Then future-proof your setup with the D902.

- Check Compatibility: Make sure the engine matches your hydraulic system and control unit requirements.

- Use OEM Resources: Reach out to your local Kubota dealer or equipment manufacturer for engine-matching guides and support.

Future of Kubota Mini Excavator Engines

Technological Advancements in the Pipeline

Kubota continues to invest in engine innovation to meet the evolving needs of compact equipment users. Expect to see improvements in:

- Electronic Fuel Injection (EFI): For even better fuel economy and smoother operation.

- Smart Diagnostics: Onboard systems that alert operators about maintenance needs before breakdowns occur.

- Enhanced Emissions Control: Kubota is working toward zero-emission solutions without compromising power, including low-NOx technologies and better particulate filtration systems.

The integration of telematics and IoT (Internet of Things) is also on the horizon. Imagine receiving real-time engine performance reports, diagnostics, and even remote tuning options.

Transition Towards Hybrid and Electric Options

As emission regulations tighten worldwide, Kubota is also exploring hybrid and fully electric power units for mini excavators. These systems aim to

- Reduce fuel consumption

- Lower environmental impact

- Provide silent operation for sensitive work environments

However, diesel engines like the D902, D722, and Z482 remain dominant for now due to their durability, cost-effectiveness, and infrastructure support. The shift will be gradual, but Kubota is already laying the groundwork for future-proof solutions.

Conclusion

Choosing between the Kubota D902, D722, and Z482 isn’t a matter of finding the “best” engine—it’s about finding the right engine for your specific needs. Each one serves a distinct purpose:

- The D902 is for power-hungry professionals who need muscle, speed, and dependability.

- The D722 offers a fantastic middle ground between performance and efficiency, ideal for daily users who need versatility.

- The Z482 thrives in ultra-compact, quiet, and fuel-conscious applications.

Kubota’s legacy of engineering excellence ensures that whichever model you pick, you’re getting reliability, serviceability, and a name that holds its value. Whether you’re digging out backyards, running underground cable, or maintaining public parks, there’s a Kubota engine that’s built for your task.

FAQs

Which Kubota engine is the most fuel-efficient?

The Z482 is the most fuel-efficient, thanks to its compact two-cylinder design and low displacement. It’s ideal for light-duty tasks with minimal fuel usage.

Can I swap engines between models?

Engine swaps are possible but require careful attention to mounting points, electrical connections, hydraulic compatibility, and weight distribution. Always consult with an experienced technician or OEM before swapping.

What’s the quietest Kubota engine?

The Z482 is the quietest, followed by the D722. Both are suitable for residential and noise-sensitive environments.

Which is best for cold weather operation?

The D902 performs best in cold conditions due to its higher power, faster warm-up time, and stronger cranking ability. All models benefit from glow plugs and proper winterization.

Are Kubota parts expensive or hard to find?

Kubota parts are widely available and reasonably priced compared to competitors. You can find both genuine and aftermarket options through dealerships, online retailers, and equipment suppliers.