An excavator is one of the most frequent pieces of construction equipment that businesses require to do new work. But it might be hard to pick the proper excavator with so many options.

This article will help you find an excavator that is right for your work, which is a good thing. Choose an excavator that fits the job you need to accomplish, the work that needs to be done, and the place where the project will be done. Make sure you have all the features you could need for future work.

It’s ideal to choose a wise partner that you can trust to bring you the proper tools and components you need for repairs and upgrades in the future. Your construction supply company should fulfill all of the following requirements and make you feel good about your choice.

Fulfill Your Expectations

The most important thing when picking the proper excavator is that it can get the task done. Check out the hydraulic systems and testing choices for your future excavator to be sure it has adequate power for your job. A lot of people will write down how powerful their system is and what tasks can be done in a complete workday because of that capacity.

More powerful hydraulic systems may help you work more efficiently and get more done because they provide you the right amount of power. But performance also means having the optimum support for your task. When choosing, think about all the things your excavator will need to do.

For your excavator, you should think about two main support options: zero tail swing or zero house swing. These setups let your operator operate safely near to walls, dig sites, and other things that get in the way.

The tail’s zero-swing lets the excavator move quickly and makes it less likely that it may accidentally hit something nearby, such a structure, equipment, or object. The zero-swing for housing keeps your operator from striking the front and sides of the excavator as they turn.

If you operate in an area with a lot of things in the way on both sides, zero-swing choices are a good choice. This setup, on the other hand, makes the excavator broader, which isn’t necessarily good for a jobsite.

The boom on modern excavators is separate from the rest of the machine, which is a big plus over the old backhoe. This lets your operator control the machine and make a sturdy base that doesn’t need to be shifted as often. You have more power and better visibility now that things are running more smoothly.

Match It to Your Site

What does the place of your employment look like? Think about it, including the risks and your present demands, as well as the ones you plan to have as your project goes through each step. To make sure you’re covered when you buy an excavator, think about all the things you could need it for.

It’s advisable to assess the excavator based on your usual work location if you have a significant business or need equipment for the long term. Some models work better on big, flat areas than on city streets with plenty of buildings and other things in the way.

Once you know where you are, think about the kinds of work that are done at your usual site. Your business needs the correct excavator to do things like reach, dig, lift, transport, and other things that you do every day. Look at your prior work and make sure you have the right measures, such how deep your digs were or how much weight they were.

To find the right excavator for your work, think about these important features:

- Power of the engine. You need a robust engine to go about your job site and do your work. When looking closely at specs, be sure to include the bore and piston stroke so you can see how strong various engines are.

- How heavy it is. The maximum operational weight is what you should pay attention to. This will include the equipment, the operator, and the load options. You don’t want an excavator that is excessively hefty and may hurt your site.

- Size. Check to see whether your location can suit your excavator. Most of the time, excavators are scaled by their tonnage, which is the same as their working weight. The more tonnage there is, the more breakout force there is.

- How much the bucket can hold. Check the sorts of buckets it can hold and the maximum capacity of the bucket choice. Buckets are one of the most typical uses for excavators.

Size Matters

As you think about your employment criteria and the people you work with, start to narrow down your search. Start by looking at the different sizes and types of excavators. Keep in mind that categories are broad and specifications might vary from one manufacturer to the next. Instead of “mini,” think of a size, like 5 tons.

Here are some of the best types of excavators:

- Small or compact. These little excavators are usually the easiest to move around. They may weigh anywhere from 2,100 pounds to just about 10 tons. A tiny is a great choice for little projects or jobs that need to be done in tight spaces, such as when you need to go around a building or work in regions with a lot of lines running through the ground. These use the least amount of power, but they will also inflict the least amount of damage to the road, sidewalk, and yard.

- Standard. Standard excavators are those that weigh between 10 and 45 tons. These are the most flexible excavators since they can work in almost any place and do most chores. They have a lot of force; thus, they will be heavy and hurt the ground they have to travel. They are robust and simple to move, but you will need a lot of area. In the construction business, they are prevalent.

- Big. These big machines, called excavators, may weigh up to 95 tons. These machines are made for heavy industrial operations. You won’t see them in cities or on job sites with a lot of hills, but they are always there to supply electricity for big building projects. Moving this machinery from job site to job site will cost a lot of money for the equipment and trailer. You will know whether you need this size and strength.

In each part, there are a lot of various ways to set things up. Modern designs make conventional and small excavators more useful for a wider range of jobs. These include the ability for the undercarriage to pull back and enable an excavator to travel through tight spaces like fence gates and then expand when they require a firm platform to do the task.

Why Use a Mini Excavator?

Some projects need the power of a regular or big excavator, but not all of them. Mini excavators have a number of benefits over bigger ones, such as:

- Less impact. Mini excavators create fewer track traces and do less harm to the earth since they are smaller and lighter.

- Smaller footprint. When a work location is tiny or busy, like a parking lot, it’s easier to use compact mini excavators.

- Easy transport. You may easily move mini excavators from one construction site to another by loading them into the back of a utility vehicle or a compact trailer.

- Low transportation weight. If you have a normal Class C California driver’s license, you might be permitted to trailer and tow a mini excavator because some Cat mini excavator models weigh less than 10,000 lbs.

Mini excavators are great for jobs that need to be done in a small space. For example, working in a backyard means needing to get through gates and around a narrow area. A tiny excavator may do the same things as a regular excavator, but on a smaller size. This may make things go a lot faster when they would have to be done by hand.

When to Use a Mini Excavator

What is a tiny excavator used for? Mini excavators may be used for a lot of different things since they can be attached to a lot of different things. Mini excavators are more useful than you may think because they are light and little. This kind of machine is an excellent choice for these four jobs:

What can you do with a tiny excavator? Mini excavators may be used for a lot of different things since they can be attached to a lot of different things. There are more things you can do with mini excavators than you may think because they are small and light. Here are four occupations where this kind of machine might be an excellent choice.

1. Utility Line Install or Repair

For excavating trenches to install or replace lines, an excavator is a fantastic instrument. When you dig with an excavator, you look directly into the trench you want to make. When you dig with a trencher, you dig behind you. You may also put your spoil where you need it instead of on the side of the trench, where you might need to utilize another tractor to transfer it.

2. Excavation

The excavator is the best tool for digging out an area. You may swing the excavator 360 degrees to dump the stuff where you wish it. Excavators do practically all of the work for pool excavation, landscaping, and construction pad excavation. Another good thing about excavators is that when you need to over-excavate a pad for compaction, you can simply meter in the material to the right thickness for optimal compaction. Another wonderful use for the excavator is to excavate footings for structures or retaining walls.

3. Demolition

A mini excavator might be quite useful if you need to take out a concrete patio or a building. You may add a hydraulic thumb to the machine to hold the debris while you break it out and load it onto the truck or trailer to haul it away. You may also add a hydraulic hammer or breaker to break up rocks or concrete slabs.

4. Drilling Holes

It’s important to have a mini excavator on construction sites where you need to drill holes in hard-to-reach places since it can move about in confined spaces. Workers don’t have to shovel by hand or use other hand equipment to drill the holes when they use a tiny excavator. You can also dig at practically any angle and reach over anything with the small excavator. Because the auger is powered by hydraulics, you can drill a hole wherever the end of the excavator stick is.

Operator Comfort Is Important

To choose the proper excavator, you need to make sure it meets your demands. This should also entail making sure that the proper excavator is paired with the right personnel.

A lot of versions are made to make the operator more comfortable by using ergonomic seats and controls. Find a cab that has a lot of space and makes it simple to reach all of the excavator’s controls and functions. Your operator can work comfortably in adjustable seats that slide side to side. This gives you ample flexibility to swiftly switch operators.

A heating and air conditioning system should also be part of the comfort equation when choosing an excavator. These ought to be strong enough to keep your area comfortable. A lot of modern cabs include controls that are like those in automobiles and trucks. Look at these and make sure the controls are clear. There should be two vents: one in front of the driver’s seat and one behind it.

If your operators will be using the excavator for a long time, comfort should be a big part of your decision. When trying to figure out how to buy an excavator, pick one that will help keep performance up instead of hurting it.

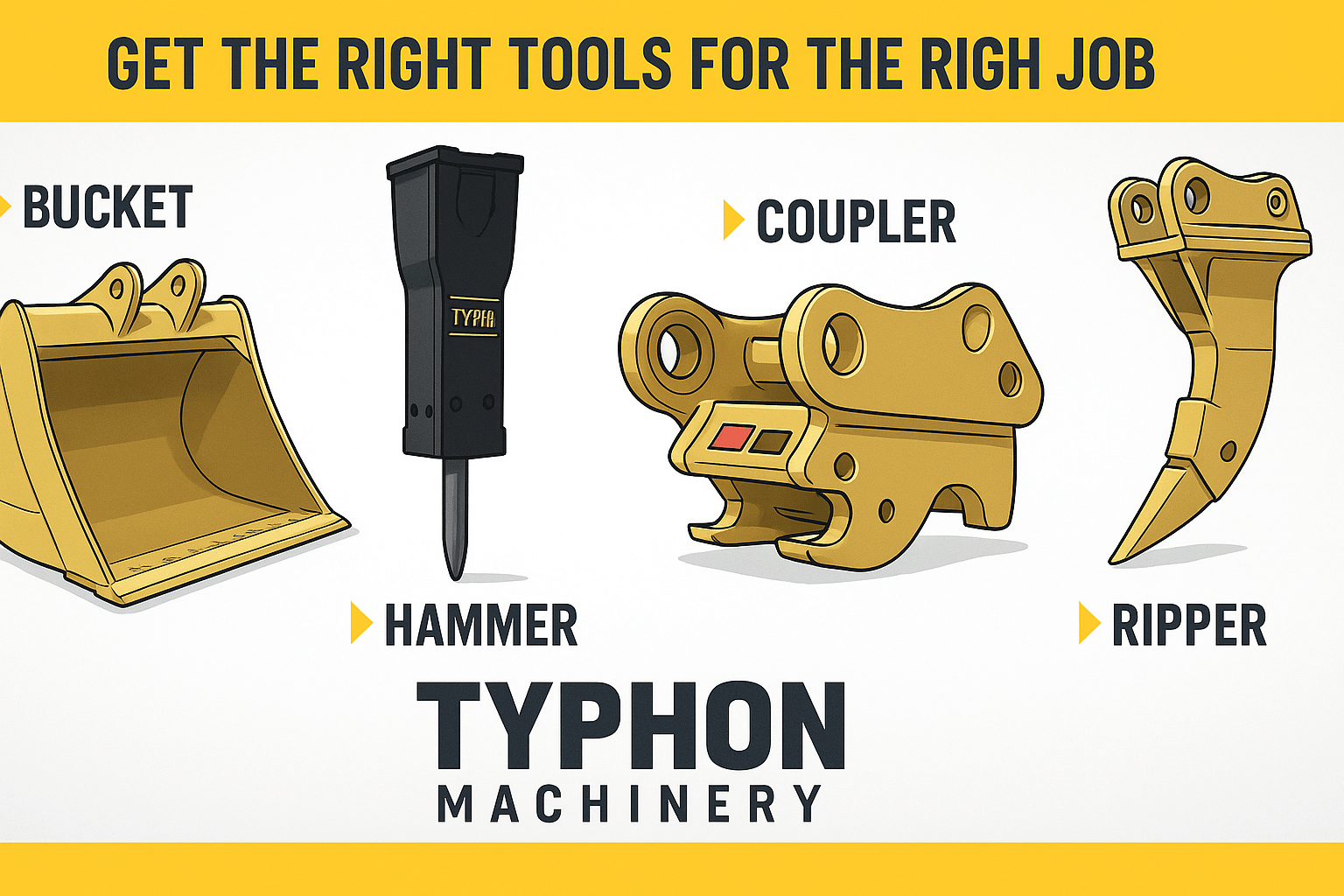

The Right Tools for the Job

When you want to do more than just dig, picking an excavator is different. If you want a machine that can do a lot of different things, you need to think about the attachments it can use. There are many various types of support equipment that may be added to excavators for different purposes.

Some of the most frequent include:

- Buckets are the most useful attachment for your excavator. They come in many various designs for digging, grading, cleaning ditches, and more, and you may choose the one that best fits your workload.

- Couplers—These attachments let your excavator easily transfer tools without having help from other people. This implies that your machine may switch between jobs as you move around the job site.

- Compaction: Pipeline contractors and site preparation can both utilize compaction wheels and vibrating plates.

- Rippers: A ripper may break up hard terrain or even ice. These are often used to support trenches and pipelines. They may also support couplers and come in a range of depths.

- Hammers: Excavators are often used to tear down structures and pavement. Using a coupler to switch between a hammer and a bucket makes this job go faster.

Most of the time, you’ll use attachments from the same company to match your excavator. This is a fantastic idea because it will assist with warranties. It also makes sure that your attachment works with the excavator’s special mounting mechanism. When using a hydraulic actuated system, it’s very vital to match your equipment with your excavator. This is because it makes it easy to change attachments with only one button push in the cab.

Additional Features for Selecting the Right Excavator

When you’re about to buy an excavator, you should also think about some extra characteristics. These might help you pick the best excavator by giving you a list of things to think about when comparing your top choices.

Some of the more notable secondary characteristics include the following:

- Features that stop vandalism. Some of these choices let you lock certain components and places on the machine so that it can’t be used or anything may be taken off. If you need to leave your excavator on-site, these are helpful. This protects your tools and work site, and it also protects you from being sued if someone gets hurt while sneaking onto your site.

- Modes of Power. Power choices for your attachments and boom are two of the several power distribution modes. Some of these will also let you give your songs more power. These methods let you boost performance in scenarios that your equipment will often confront.

- Controls for Hydraulics. To aid with control, newer excavators have added top-of-the-line hydraulics to the cab. It helps your operator move more accurately and makes the whole procedure easier. Ergonomic arrangements will also make it easier for your operator to do their job.

These things are really crucial to think about when you’re trying to figure out how to acquire an excavator.

Before Choosing an Excavator

Before you buy an excavator, you should try it out for yourself. Before you provide money to someone, you should have a good, hands-on experience with the machine. This phase of the procedure is equally as crucial as picking the type you want to utilize because no two excavators are the same.

Check the following things as you look at your possible excavator:

- Watch how it starts. It’s preferable for the engine to start immediately than to have to wait for the battery to charge.

- Look for any leaks or smoke. It’s normal for an AC system to leak some water and for engines to make a little smoke. Always check to see whether these things are normal for the equipment. Check for any fluid leaks and make sure they aren’t in a system that is important.

- Check the oil and other fluids in the machine to see how they are doing. These should be new, but if someone is trying to sell you a machine with old hydraulic or other oils, it might be a hint that something is wrong.

- Quickly glance at the engine and wiring when you open it up. You want everything to look excellent, and you want the wiring to seem

- professional. If you see electrical tape all over the place, it might be an indication of trouble.

Check out the features and tools. For instance, you may check the wear on the slew ring by raising the boom and moving the body by hand. For swivel booms, a little motion in the swivel mechanism is fine. When you do move it, you should watch for too much movement or signs of wear.

A comprehensive inspection may save you a lot of trouble, damages, and money. Plus, it helps you keep your personnel safe, which is the most important benefit of all.

Choosing the Right Excavator

It takes time to learn how to acquire an excavator since you have to make sure it meets all of your company’s needs.

An excavator is a great piece of equipment to have since it can be used for many different things during the whole construction process. Excavators are always in the construction yard. They grade the ground for your foundation, raise goods to your workers, and provide power for your demolition.