Maintain the Hydraulic System of a Mini Excavator

Among mini excavators, hydraulic systems are the most important. The hydraulic pressure is almost everything and it includes the ones responsible for the cataloging of the operative functions of a mini excavator in the hydraulic energy sector. If the hydraulic system is well maintained, it guarantees a very powerful, smooth, and responsive performance of the machine.

But if it is not taken care of properly, one may end up with a lot of money to spend, a lack of efficient work, or even the occurrence of catastrophic events.

Today’s blog main purpose is to explain essential points of the steps on how to inspect, service, and maintain the hydraulic system of a mini excavator in such a way that it happens without stopping or breaking down, it functions for a long time and is efficient in terms of productivity thus increasing labor productivity and the capacity of the working machine.

Table of Contents

- Understanding the Hydraulic System in Mini Excavators

- Safety First: Precautions Before Servicing

- How to Inspect the Hydraulic System

- Routine Hydraulic Maintenance Checklist

- How to Replace Hydraulic Filters and Fluids

- Common Hydraulic Problems and Troubleshooting Tips

- Importance of Hydraulic Fluid Quality and Storage

- Using the Right Replacement Parts and Fluids

- Long-Term Maintenance Strategy

- Useful Tools and Accessories

- Related Products from American Excavator Store

- Frequently Asked Questions (FAQ)

Here is the detailed overview on the topic:

Understanding the Hydraulic System in Mini Excavators

A hydraulic system in a mini excavator is made up to convert mechanical energy into fluid power. The working principle is based on Pascal’s Law, which states that the pressure exerted on a fluid is distributed in all directions equally. This feature offers the advantage of the operation of cylinders, swing arms, buckets, and also the inclusion of attachments such as augers or breakers.

Core components include

- Hydraulic Pump: Generates pressure.

- Control Valves: Regulate flow to actuators.

- Cylinders and Motors: Translate fluid power into mechanical movement.

- Hydraulic Lines & Hoses: Carry pressurized fluid.

- Reservoir: Stores hydraulic oil.

- Filters & Coolers: Clean and manage fluid temperature.

Safety First: Precautions Before Servicing

Before beginning inspection or servicing, ensure that safety protocols are strictly followed.

- Turn off the engine and let the system cool.

- Release hydraulic pressure: Engage the controls multiple times after engine shutoff to purge pressure.

- Use PPE: Safety glasses, gloves, steel-toe boots.

- Check surroundings: Ensure the machine is parked on a level surface with outriggers (if any) deployed.

- Tag out: Use lock-out/tag-out systems when available.

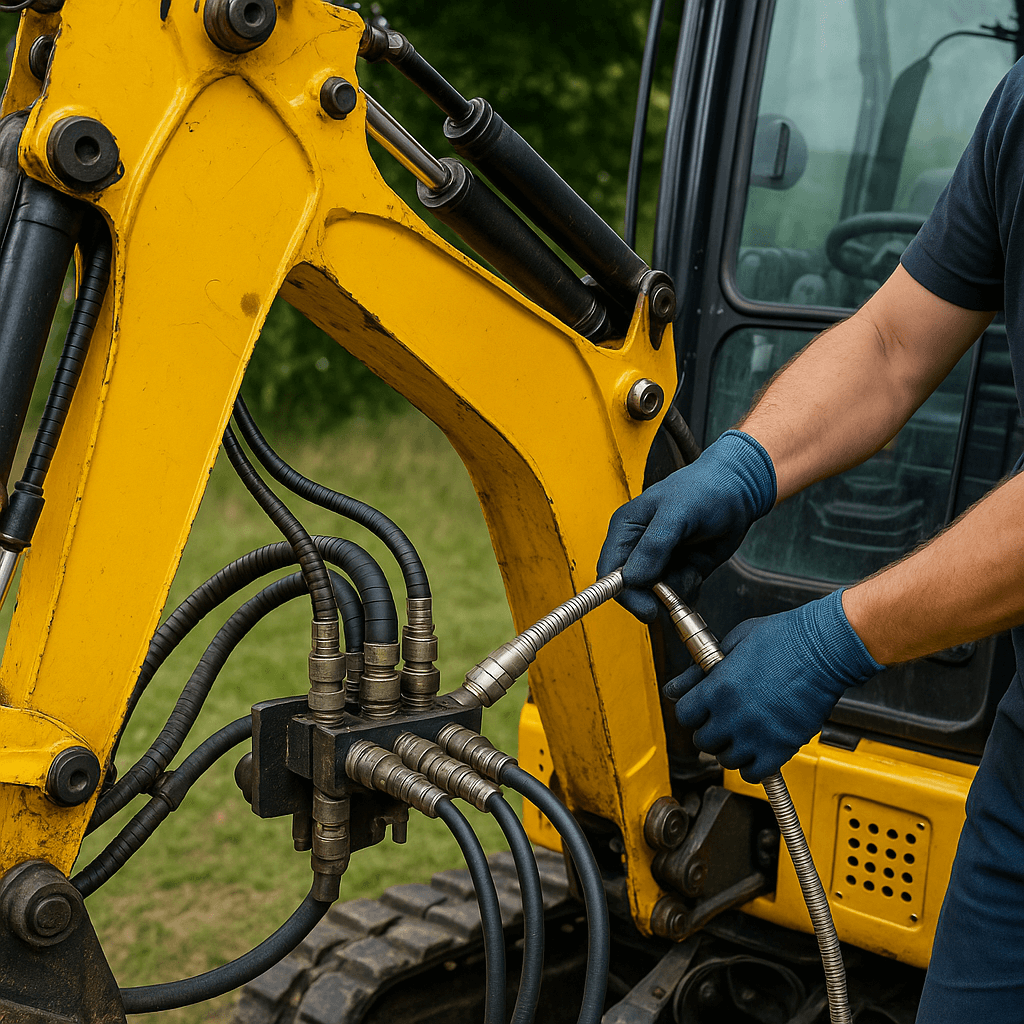

How to Inspect the Hydraulic System

Regular inspection helps find and fix problems early. Carry out these checks at least once every 50 hours of machine activity or weekly:

Visual Inspection:

- Look for oil leaks around hoses, fittings, and the reservoir.

- Inspect hoses for wear, cracking, or bulging.

- Check the hydraulic cylinders for scoring, rust, or signs of leakages at the seals.

- Make sure connectors and quick couplers are free from defects

Fluid Level Check

- Go by the dipstick or sight glass on the reservoir.

- Check level when machine is stopped and on a level surface.

Oil Condition

- Milky oil = water contamination.

- Black/burnt oil = overheating or long use.

- Sludgy oil = severe contamination.

Pressure Test

- Utilize a hydraulic pressure gauge to execute a test of the pump and valve output.

- Check the manufacturer’s specifications for the PSI ratings.

Routine Hydraulic Maintenance Checklist

Daily Tasks

- Inspect the fluid level and fill up and off.

- Search for fresh leaks.

- Wipe the dirt off of the outside of the hydraulic parts.

Weekly Tasks

- Examine the hoses and fittings for damage.

- Apply grease through hydraulic fittings if needed.

Monthly/Quarterly Tasks

- Replace the return filters.

- Dispose of the old oil and add new oil (as required).

- Inspect pressure settings.

Annual Tasks (or 1000 hours)

- Clean the system completely by flushing it.

- Change hoses that have high wear and tear.

- Check the pump and cylinder internals if you can access them carefully.

How to Replace Hydraulic Filters and Fluids

Changing Hydraulic Fluid

- Make sure that the machine is warm so that the oil will flow easily.

- Shut down the engine and relieve the system of its pressure.

- E vacuate the old oil from the reservoir and flush the system if necessary.

- Top up with the recommended oil (refer to the manual).

- Run the engine for a short time in order to make the new oil circulate and then re-check the level.

- Make sure to use only OEM-grade hydraulic fluid or a reputed brand with the product that follows ISO VG 46 or 68 standards.

Replacing Hydraulic Filters

- Identify the return line filter (usually near the tank).

- Loosen the old filter, clean the mount and install a new one.

- If it is demanded, fill the filter.

- Seal the filter, and the remaining oil should be managed responsibly and properly.

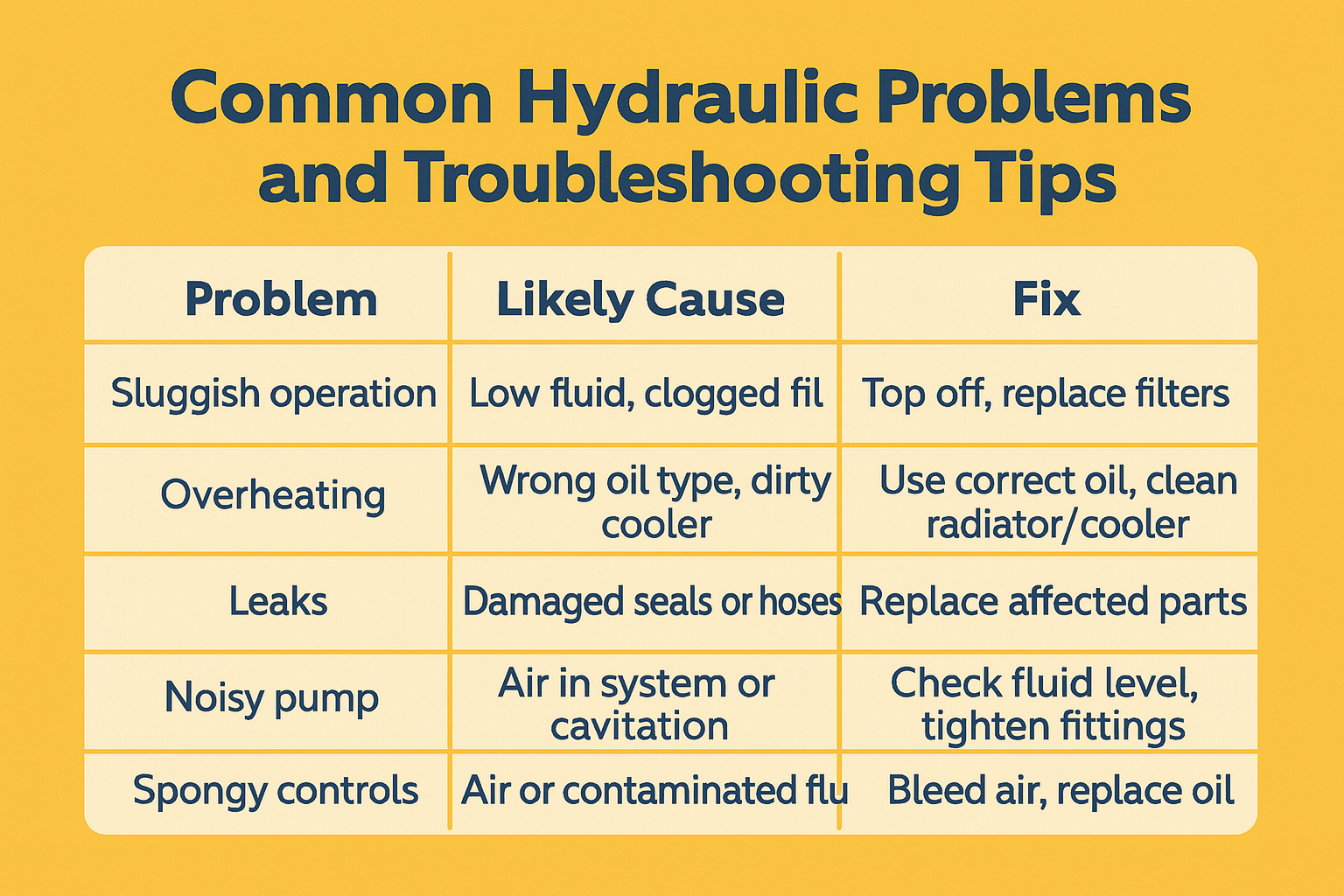

Common Hydraulic Problems and Troubleshooting Tips

| Problem | Likely Cause | Fix |

|---|---|---|

| Sluggish operation | Low fluid, clogged filters | Top off, replace filters |

| Overheating | Wrong oil type, dirty cooler | Use correct oil, clean radiator/cooler |

| Leaks | Damaged seals or hoses | Replace affected parts |

| Noisy pump | Air in system or cavitation | Check fluid level, tighten fittings |

| Spongy controls | Air or contaminated fluid | Bleed air, replace oil |

Importance of Hydraulic Fluid Quality and Storage

Inferior hydraulic fluids are capable of causing a breakdown in your system, so you should always:

- Use airtight containers to store it.

- Reserve the fluid in a spot that is not sunny, is dry and cool.

- Consider whether the manufacturer has given standards such as J20C, ISO VG46, or AW68.

Using the Right Replacement Parts and Fluids

Besides, the combos of the hydraulic oil types and reusing of the drain mini excavators contain plenty of the specs of the hydraulic parts that are not omni-compliant. If in doubt, do not go for a part without confirmation of compatibility.

Tips:

- Strictly observe the pressure (both the burst and working pressure) recommended for hoses.

- Always use hydraulic thread sealant that is approved for the use of hydraulics.

- For most of the cases, use OEM or buy aftermarket filters and filter oil.

- See a selection of products like hydraulic fluid, seals, quick couplers, and filter kits available American Excavator Store for compatibility check.

Long-Term Maintenance Strategy

A systematic preventive maintenance practice on your excavator’s hydraulic system can extend its lifespan up to two times. Follow these guidelines:

- Keep a record of the regular service intervals.

- Conduct employee training sessions frequently.

- Have a real-time monitoring system in place through installing pressure gauges.

- You can probably use condition monitoring sensors if you have large numbers of machines and vehicles being used.

- Monitor control valves and pumps through diagnostic inspections performed during the scheduled service periods.

Useful Tools and Accessories

The following tool and accessories will make work easier:

- Hydraulic Pressure Testing Kit

- Filter Wrench and Drip Tray

- Thread Seal Tape (Hydraulic Rated)

- Hose Repair Kit

- Infrared Thermometer

- Clean Funnels and Oil Transfer Pumps

Any of these items are available for purchase from a nearby dealer or the American Excavator Store.

Related Products from American Excavator Store

If you need tools and products to maintain your hydraulic system, take note of the following essential items:

- Premium Hydraulic Oil (ISO VG 46 / 68)

- Return and Suction Filters (OEM Match)

- Seal Kits for Cylinders

- Hydraulic Hose Assemblies

- Quick Disconnect Couplers

- Portable Hydraulic Testers

All these products are compatible with major brands such as Bobcat, Kubota, CAT, Yanmar, and Takeuchi.

Final Thoughts

By regular testing and maintenance of your mini excavator’s hydraulic system, you can avoid unnecessary problems and make it more efficient on the worksite. This guide is a great asset whether you are an independent contractor or the owner of a rental fleet, as it gives you the tools to manage the machine effectively and without any issues.

Our fully stocked range of spare parts for your hydraulic system is waiting for you at the American Excavator Store. All our compact excavator filters and full service kits will be matched accordingly.

Frequently Asked Questions (FAQ)

Q1. How often should I change hydraulic oil in a mini excavator?

Every 1000 to 2000 operating hours or once a year, whichever comes first. It is very critical that you always refer the machine’s manual for actual usage hours.

Q2. What type of hydraulic oil should I use?

The recommended hydraulic oil is anti-wear hydraulic oil that is ISO VG 46 or 68. Some machines might demand that you use J20C or private oil blends – check the owner’s manual.

Q3. What are the signs of a failing hydraulic pump?

Be aware of the following:

- Weird noises like whining

- Low hydraulic pressure

- Cylinder movement becomes slow

- Increased fluid temperature

Q4. Can I repair a leaking hydraulic cylinder myself?

Yes, you can fix it using a seal kit and the proper tools. Otherwise, it is best to have a professional service the cylinder to rectify the leaking.

Q5. Is it okay to mix hydraulic oil brands?

Only in case the oils are of the same type and spec (e.g., both ISO VG 46 AW). The mixing of incompatible fluids can result in foaming, breakdown, or filter clogging of the system.

Q6. Can the low temperature fail hydraulic systems?

Definitely. Please insert oil of a lower viscosity in winter and allow the machine to idle for a longer period before using heavy power to have the fluid warm up faster.