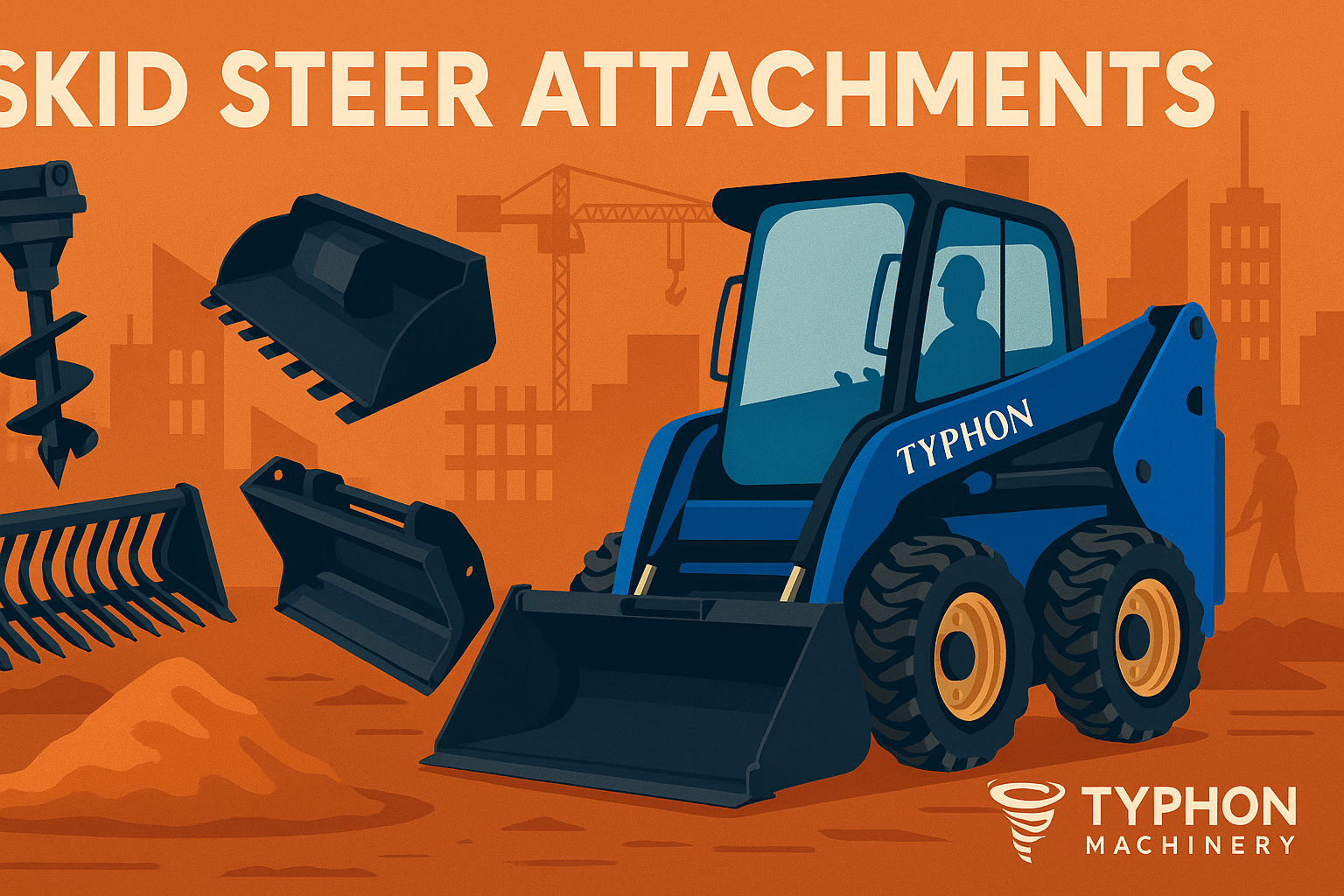

The Complete Guide to Skid Steer Attachments: Boosting Productivity & ROI

Would you like new tools for your business to give you better results and to have a greater return on your investment for your compact equipment? In this guide, you will learn what to do step by step to choose the best and to use the skid steer attachments in such a way that your skid steer loader will become your most productive and efficient worker.

If you are in construction, gardening, farming, logging, or property maintenance, the compatible skid steer implements can give you access to different functionalities, as well as save on operating costs and increase the return on your investment (ROI).

Picture this instead of going shopping for various special machines you think are perfect for you, if you’re one of those people who can now utilize your skid steer as the main equipment for all the chores you want to be done, it’s even possible to do it at a higher speed. The potential of tasks in the skid steer is a sight to behold, from materials handling to the preparation of the site to digging and up to forest clearing.

We assure you that you will love to dive into the issue; the pros share their cleaning lines, the secrets about the maintenance of a skid steer, the practical use of tractors in a versatile way, and the sure way to have the lowest possible consumable costs for the operation.

Giving Life to Your Skid Steer Loader

- Implement Choice: Make your skid steer a good helper for any construction project by purchasing a proper attachment and you will be free from the burden of buying a separate machine, which is not necessary.

- Financial Theme & Efficiency: Skid steer equipment, such as simple buckets or hydraulic breakers and grapple buckets, are not only the most important but also the most effective tools to increase productivity and reduce the labor costs significantly.

- Adaptability & Versatility: By using the quick attachment changes and the multifunctional hooks, the skid loader becomes an efficient tool to use in construction and landscaping or tree care sectors, as it can easily go from task to task, thereby calling for no different ones.

- Durability & Longevity: The choice to opt for attachments of high quality made from materials that are durable will automatically lead to the long-time working of the same. This will be in addition to the fact that there will be saved costs and thus the return on investment will be higher. Proper equipment maintenance is crucial for sustained performance.

- Stand-On Skid Steer Optimization: When the proper tools are linked with stand-on skid steers, the latter will offer high maneuverability and flexibility, making them ideal for chameleon-like small-time players and diverse projects.

Essential Skid Steer Attachments for Maximum Efficiency

Make your skid loader into a profit-making machine by using these must-have skid steer tools:

Multi-Purpose Attachments:

The Foundation of Efficiency Automation has become the trendsetter in all areas of life. Any repetitive task can be given to robots or machines, and the operators will be able to do more demanding jobs. If you waste your resources moving things and nothing is done, that is the last thing you want toen in terms of efficiency.

- 4-in-1 Bucket: This key, high-end product brings several functions together making a giant leap in the building machines that people were used to. The span goes from a regular loader shovel to a dozer blade, grapple, and a clam unit. Subsequently, attachment changes are significantly less and at the same time, the whole productivity is enhanced.

- Pallet Forks: Apart from being the basic ones used in the handling of materials, pallet forks are the best options to be utilized in the sector of moving big objects, setting up construction materials, and even light grading work.

Attachments for Specific Tasks: Efficiency and Effectiveness

One machine does it all but certain operations need specific skid steer attachments to be done most efficiently. This is the main theme one can develop from the text above. Click here if you’d like to read more on the topic.

- Augers: Indispensable for the exact, safe, and quick drilling of holes in the construction and landscaping industries. The correct auger attachment not only increases installation but saves the workers from a lot of work.

- Brush Cutters & Mulchers: Indispensable for land clearing and managing vegetation issues. The equipment, apart from changing your skid steer into a powerful landscaping machine, can as well handle coarse brush and small trees with ease.

- Loader Attachments for Snow Removal: They are the newly developed equipment integrating snow plows and snow blowers which facilitate skid steers for efficient winter work and guarantee that productivity levels remain high. What is more, the snow pushers and blowers may be used for keeping free from snow as well as for moving the snow where there are no alternative sources of power.

Hybridizing universal multi-purpose with specialized instruments will create an ideal set of tools with that there will be better opportunities for enhancing the productivity of the skid steer, having fewer changes of the equipment, and coping with various tasks in a highly effective manner.

The Right Fit of your Operations Through Selecting the Most Competent Attachments

The initial stage with your skid steer add-ons is choosing the right one that parts are in your management range.

Selection of Attachments that Matches Job Demands

- Know Your Task: Before you start working, consider your work, materials needed, and the number of times you will go back and forth. If you have multiple tasks, you can focus on getting attachments that can do all the work required effectively.

- Detailed Needs Assessment: Summarize from the text the main usage and if possible the secondary usage to ensure that the tool is used at best and it brings back the most money (ROI). For instance, the bucket-fork combination is an example of dual-function tools that are able to facilitate both loose material and palletized loads.

Quality and Durability Considerations

- Go for Quality: Opt for high-end attachments that might be more expensive at first but they greatly contribute to the decrease in cost-effectiveness by providing service for an extended period of time and by being consistently reliable.

- Check the Material: To determine the quality of the materials used, the respect that the manufacturer holds, the wear-resistant materials used, the components that are reinforcement of the stress points, the attachment’s ability to resist wear due to continuous usage and the quality of the welding which should not be overlooked.

- Guarantee & After Sales Service: Look for the warranty and the post-sales service as it assures more cover in case the attachment is damaged or needs spare parts which are very important for your business to continue without interruption.

Quality Criteria of an attachment are the match type that fits best the operational requirements, gives priority to the later and is also the most economical on a long-term basis in the execution of single tasks.

Maximizing Versatility Through Smart Attachment Usage

Skid steer loader attachment options and their adaptability, if used well, are indispensable for gaining a competitive edge in the market.

Examples of Multi-Functional Applications

These heavy vehicles have showcased their incredible adaptability by being able to cater to various industries:

4-in-1 Bucket:

- Material loading and unloading

- Precise grading and leveling

- Debris cleanup and removal

- Light dozing operations

- Grapple Bucket with Fork Attachments:

- Moving and stacking palletized materials

- Handling irregular-shaped objects

- Clearing brush and vegetation

- Transporting loose materials efficiently

By becoming proficient in these multi-functional attachments, not only can you meaningfully decrease the need for specialized machines but at the same time keep the working levels high in terms of productivity. An appropriate combination of a skid steer and the right attachments will lead to a serious halving of the costs related to the use of multiple dedicated machines and a consequent improvement in operational efficiency.

Present-day quick-attach systems give the go-ahead for an operator to carry out the process of switching from one tool to another in a matter of minutes and consequently to kill two birds with one stone: to maximize productivity and to minimize downtime. Such flexibility is irreplaceable in cases of the projects that are very different one from another or in cases of strict deadlines.

The attuned use of multi-functional attachments can convert your skid steer into a multi-purpose working animal to save on the equipment numbers and offensively use your operational effectiveness along with the ability to make it more cost-efficient across different applications.

Cost-Effective Operations with Skid Steer Attachments

Customizing your skid steer by teaming it up with the right attachments is the efficient direct to cost-effective operations route.

Labor Cost Reduction

- Reduced Manpower, Increased Productivity: With suitable skid steer attachments, one can achieve a reduction in man-hours as well as an increase in productivity. For example, a brush grapple attachment on a loader can cut the number of labor needed from 3-4 people down to just one and be safer for the workers, thus reducing the chances of injury.

- Get the Right Attachment First Time: The smart choice of an attachment allows for avoiding other special equipment procurement. Teamed up with pallet forks the bucket attachment is flexible for both material delivery and loading operations without extra costs to be made.

- Attachments with Higher ROI: Put the most frequently used attachment on your priority list that lead to the reduction of the workforce as well as they usually pay for themselves in months.

- Take Care of Your Money: Regular service for the attachment is a guarantee of the cost-effectiveness of both the machine and the company, avoids the need for repairs or replacement in case of an unexpected machine break down, and thus is more productive and less time-consuming.

The effective utilization of attachments, in skid steers, can save significant amounts of money on labor and equipment, which, in turn, offers high productivity.

Stand-On Skid Steer Optimization

The right stand-on skid steer size selection is the key to operational efficiency.

Size Selection and Applications

- Smaller Stand-On Skid Steers: They are better than the large ones when confined areas are considered, so they are mainly used for residential projects. Moreover, the enhanced maneuverability which is due to their small size allows them to pass through the narrowest gates and smallest pathways, which makes them the most suitable equipment’s for landscaping and light construction work. Generally having 24 to 36 inches width are mostly used in gardening and construction.

- Larger Stand-On Skid Steers: They are strong in the market and are probably used by the toughest clients of the commercial department. Most of the time, they come with the highest lifting power and the most durable hydraulic systems since they are suitable for the most demanding tasks, in bulk material handling, and excavation. A wider stance results in better stability when carrying heavier loads and on uneven ground.

The appropriate size should be decided based on the places where work is normally done, the features of the project, and the maximum weight the machine should carry. The small size type is perfect for city center or indoor reconstructions with a knock down drill, the large one for big projects or demolition works.

Opt for the size of the walk-behind skid steer loader that suits your workplace and has the required performance characteristics; in a nutshell – very compact ones will cope with space limits, and the larger models will make heavy works lighter.

Conclusion: Put Money into Your Business’ Future Growth

Effective decision-making may maximize the efficiency of your skid steer loader, transforming it into a multipurpose powerhouse. Grow your business by selecting skid steer equipment that fits the work, clean it appropriately, and prioritize essential activities for automation to save costs and boost production via sustainable practices.

When doing tasks such as land removal, building, or tree care, use attachments with numerous combinations for optimal results. Each instrument, from grapple buckets to auger attachments, has unique and efficient functions.

In addition to its replaceable characteristics, well-maintained skid steer tools provide a long-lasting collaboration.

No pause! Now is the time to assess your connection inventory and identify opportunities for improvement. When you purchase attachments, you invest in the future growth of your firm, not just the equipment.

FAQs: Your Questions Answered

Q1: How regularly do I need to lubricate the skid steer attachments to keep the productivity at the highest level for my project?

A1: The first thing that stands out is a regularity of maintenance. The user should start with a weekly schedule which includes greasing the parts that are moving, examining the hydraulic connections, and checking wear points. Clean the attachments after each application, and store them properly. The equipment will get a quite long and quality service if one does a very thorough repair every 100-150 operating hours.

Q2: What is the average period of the return of the investment made in new skid steer attachments after purchasing?

A2: On average, the payback time for the investment is mostly 6-12 months for the contractors, which is determined by the usage frequency and the kind of job of the users. Attachments that are highly in demand, such as grapple buckets and pallet forks, can typically be in a payback situation in a shorter matter of time, due to labor’s costs and the overall efficiency increment in a project.

Q3: Is it permissible to team up implements manufactured by the various producers alongside my skid steer?

A3: Sure, most of the attachments are suitable for a wide range of brands, as long as they fit your skid steer’s mounting plate system. However, at the time of purchase, one has to remember to not only check the hydraulic flow requirements but also the weight capacity specifications with full attention to avoid getting some implements that are not even suitable for your vehicle.

Q4: Which factors should influence my decision in purchasing or renting skid steer attachments?

A4: The purchase or lease decision is very important, and the selection should be based on factors such as the project’s frequency, storage space, maintenance capacity and the initial investment costs. If you plan on using the attachment for more than 60% of the time, buying will be the better choice. Renting may make sense for unusual-duty attachments.

Q5: What should I do to ensure that my hydraulic breaker attachment lasts a long time?

A5: Follow the right material for the tool, avoid dry firing carry out regular oiling, and maintain a 90°-angle tool position. The regular inspection of wear bushings and retainer pins will markedly lengthen the life of the attachment.

Q6: What steps should be taken to ensure safety while changing attachments?

A6: Shut down the machine completely, depressurize the hydraulic system, and make sure all safety features are applied. When attaching and removing parts, use safe lifting techniques, wear the proper PPE, and only start the machine after confirming hydraulic connections.