Operating an excavator requires knowledge of which joystick patterns govern the boom, bucket, dipper, and swing. Operator control patterns are in two varieties: ISO and SAE. This article clarifies the distinction between the two and offers vital excavator safety advice.

ISO vs. SAE: Excavator Joystick Control Patterns

No matter what size excavator you’re using, the controls will work in the same way. The two main excavator control patterns are ISO, which is from the International Organization for Standardization, and SAE, established by the Society of Automotive Engineers.

ISO pattern is the most common and is often called “CAT controls” or “excavator controls” (because it’s what CAT machines often use). SAE is the US standard and is often called “John Deere Controls” or “backhoe controls” (because it’s what John Deere machines often use) or as “backhoe controls” (because that is the excavator that is used).

Some of the brand new models may feature a handle for changing the control pattern, which will depend on your machine. This might be located under the foot in the cab or behind a panel.

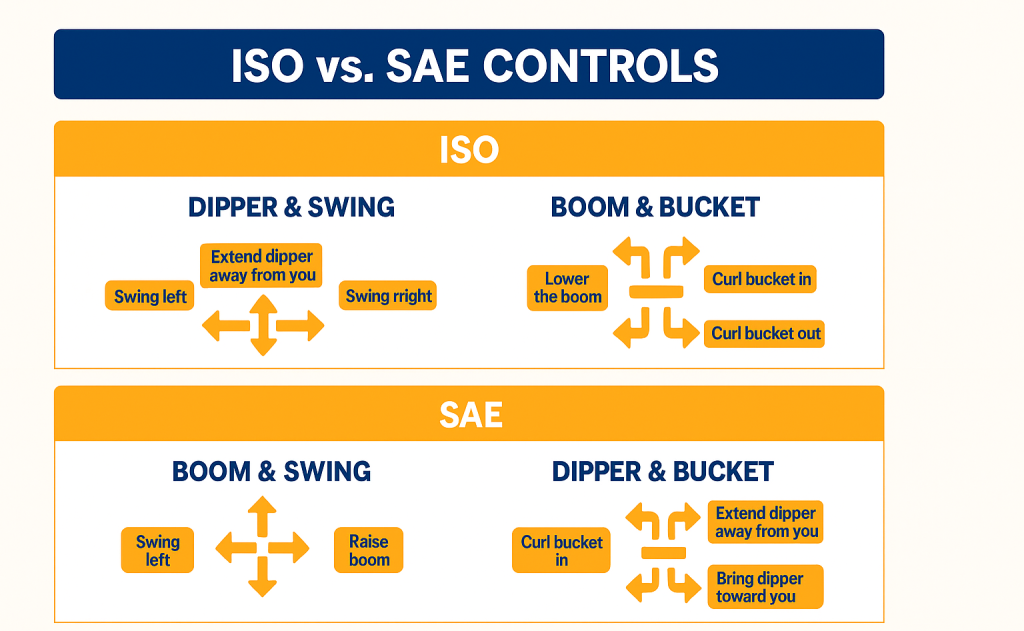

The thing that distinguishes the two patterns is that the ISO controls have the right-hand lever for the boom and bucket and the left-hand one for the dipper (stick) and the swing, while the SAE controls the right one for the dipper (stick) and the bucket and the left one for the boom and the swing. Your machine will probably be equipped with a card that specifies the pattern it uses.

ISO Controls

The most common setup for operator controls, the ISO pattern is as follows:

- Left-hand lever (dipper and swing):

- Toward you: Bring dipper (stick) toward you

- Away from you: Extend dipper (stick) away from you

- Left: Swing left

- Right: Swing right

- Right-hand lever (boom and bucket):

- Toward you: Raise the boom

- Away from you: Lower the boom

- Left: Curl bucket in (to close)

- Right: Curl bucket out (to dump materials)

SAE Controls

Unlike ISO, the SAE pattern uses the left-hand joystick for the boom and swing and the right-hand joystick for the dipper and bucket. Swing is controlled by left-hand joystick in both control standards. The SAE pattern is:

- Left-hand lever (boom and swing):

- Toward you: Raise the boom

- Away from you: Lower the boom

- Left: Swing left

- Right: Swing right

- Right-hand lever (dipper and bucket):

- Toward you: Bring dipper toward you

- Away from you: Extend dipper away from you

- Left: Curl bucket in (to close)

- Right: Curl bucket out (to dump materials)

How to Operate an Excavator (How to Use Excavator Controls)

Ensure the door is fastened and fixed to the side of the excavator before you enter so you may use the handle to securely climb in and so the wind doesn’t blow it shut against you. Climb in keeping three points of contact. Once inside the cab, follow these instructions:

- First, always put on your seat belt.

- Close the door and unlock it.

- Before you begin running the excavator, be sure you are aware of the controls.

Driving and Parking

Follow these instructions first: then move the excavator.

- To start the excavator, turn the key.

- Look for problem codes on the display and make sure it has gasoline.

- Engage the safety lock lever; the controls will not function until it is unlocked.

One for each track, two track pedals exist. You may also push with your feet as these include foot pedals and hand controls. Pushing forward advances the track; pushing back moves it back.

So, you will advance the excavator by pushing both controls forward. To go back, pull back on both. Steer and control the excavator using a mix of pedals. If your cab is squared up to the tracks, you may find it easier to operate the excavator since the alignment is obvious.

Park the excavator by turning off the power using the key, lowering the bucket to the ground, and putting the safety lock lever down.

Digging and Trenching

Line up in a straight line for the maximum stability when digging. The following advice will enable you to know how to use the excavator bucket to dig:

- Then drop the dipper/stick and bucket all the way out until you are around one foot off the ground.

- Point the bucket teeth down, drop it to puncture the earth, and then curve the bucket in to dig and fill the bucket.

- Swing left (or right) to dump after raising the bucket five to six feet off the ground.

- Repeat the action.

With greater experience, you may simultaneously use both levers to scrape a tiny layer off the surface of the earth.

Backfilling

Backfill by reversing the digging directions. The key distinction is that you do not have to lift the bucket so high. You can scrape and swing at once to fill the hole more rapidly. As you swing back or sideways, you might be able to operate an excavator for flatten the bucket and utilize the back or side to force the material into the hole. Avoid doing this with big items or a lot of stuff.

Grading

An excavator can be used to alter a piece of land’s grade or slope in order to facilitate water flow or to build on a construction site. The procedures listed below can be used to learn controls to master excavator operation with a grading attachment or the excavator bucket.

- To loosen the dirt, scrape the ground with the bucket while pointing it directly down.

- To scrape and collect the debris in the area you wish to lift, pull the bucket directly back along the ground. Spread it evenly using the bucket’s bottom.

- To get a uniform grade, keep the bucket at a constant angle.

Are Backhoe and Excavator Controls the Same?

Both SAE and ISO controls are available for many contemporary excavators and backhoes. However, in the past, excavators usually ran on ISO and backhoes on SAE.

These days, excavators and backhoes may have similar joystick control patterns, but the machine’s overall controls are distinct. Additionally, controls vary by machine and company. Furthermore, a backhoe’s pedals and controls differ from those of an excavator with tracks since it has wheels and a front loader.

Excavator Safety Tips

You should adhere to appropriate safety procedures whether you intend to operate a mini-excavator or another kind of excavator in order to avoid mishaps.

1. Conduct a Pre-Operation Safety Check

Before using an excavator, perform a pre-operation safety check to make sure everything is in working condition and that you and anybody nearby can safely operate the machine. Additionally, these safety inspections save small problems from growing worse and extend the life of your equipment.

These should be part of your safety inspection:

- Examine the surroundings for any dangers.

- Examine the machine to make sure no parts are damaged.

- Examine the machine’s underside for leaks or damage.

- Look for loose or missing pieces and tension in the tracks.

- Examine the bucket and boom.

- Verify the filters, gasoline, and fluid levels.

- Check the controls and lights.

2. Be Aware of Your Surroundings

On the job site, always be aware of your surroundings and keep a look out for other people and equipment. When excavating or driving, keep an eye out for overhead and subterranean utility wires. Keep the bucket horizontal and one to two feet off the ground for optimal visibility. You might want to lower the dipper and curl the bucket all the way in when there are risks overhead. But be aware that this makes you less visible in front.

3. Maintain Your Equipment

To learn how to use and maintain your equipment properly, always refer to the operator handbook. It will introduce you to your excavator’s components, controls and safety features, and other crucial details. Use caution when using older construction equipment if you are unsure of its maintenance history.

Purchase an Excavator from Typhon Machinery

Are you seeking to invest in a highly reliable, superior-performance excavator? If you are seeking a partner who can provide you with top-notch, innovative, and budget-friendly products, Typhon Machinery is the ideal choice. No matter if it is a farm, a building, a garden, or just an industrial project you want to deal with, Typhon has a wide range of compact and full-size excavators for the job.

Typhon Machinery is a company that excels at quality and performance. We gather our engines from all over the world, for example, Kubota and Yanmar, because they are the most economically conscious and powerful. To put it more simply, our hydraulic systems are quite in demand by various customers for their excellent control of the most precise, quickest, and fuel-saving response in addition to digging, even if the works are limited.

One of our units is that of a mini excavator, which is the best solution for small working areas and the economy and capability of a mid-size machine that can carry out heavy-duty projects with no hassle. Every model is equipped with the most functional and modern driver control panels, the comfortable space for the operator, easy access to the engine, and the possibility of adding some peripherals such as a hydraulic thumb, auger, or a breaker in order to cover any additional functionality.

What is there in Typhon Machinery that you will not find in other companies?

- Quality Assurance: Compliance with the international standards of quality and safety is the first priority for every machine that we manufacture.

- Competitive Pricing: Despite the equipment being of the highest quality, it won’t break the budget.

- After-Sales Support: Your pleasure of a dedicated customer service team with some technical support and spare parts whenever you’re in need of them.

When you purchase from Typhon Machinery, you’re not just buying an excavator — you’re making an investment in reliability, innovation, and long-term performance.

Contact us today to find the perfect Typhon excavator for your needs and experience the difference!