Our Skid Steer Attachments are assembled to deliver exceptional, long-lasting performance. To guarantee years of trouble-free benefits, we do ask one thing of our clients: Please give the same maintenance to your attachments as you give to your skid steer. Attachments give skid steers the ability to move earth, clear brush, build fences, plow snow, and much more. So, every auger, bucket, grapple, cutter, trencher, and tiller earns the exact attention as your machine.

6 Maintenance Tips for Your Skid Steer Attachments

Keep Downtime Down

Whether you own an easy bale spear or a sophisticated snowblower attachment, the right maintenance is critical to protecting your asset. This is essential when you suppose the impact that equipment downtime can have on your farm, business, or personal-use tasks. Every minute an extension is down, it chips away at longevity and profitability. So, hold that Skid Steer Attachments ship-shape with this six-step list, and you’ll be one happy trailer.

1. Read Your Manual

When you obtain your Skid Steer Attachments home, pour yourself a cup of coffee and pose with your new manual. Read it, page to page. It’ll put all those necessary supervision tips in your mind and ready you for effective workdays. Keep the manual in a safe zone so that if you run into any problems, you can quickly consult it for the explanations you require. Eventually, perform ALL suggested maintenance according to the timetable–it’ll keep you headaches down the road.

2. Lubricate Liberally

Grease is affordable, but repairs aren’t. Keep your Skid Steer Attachments charitably greased and remember, too much is always more useful than too little. Relying on your attachment and tasks, here are three grease classes that’ll keep you protected:

Multi-purpose #2

Designed for normal applications to supply lubrication, control rust, and corrosion, and deliver safety under heavy and shock loads.

Heavy-duty

Holds moly for more reasonable adherence to all characters. It offers water resistance, severe pressure capability, pump capability in cold temperatures, and reasonable seal compatibility.

High-performance

Formulated to deliver high-temperature performance in extreme operating states. It’s planned for lube points with sliding and pivoting conditioning.

3. Inspect Thoroughly

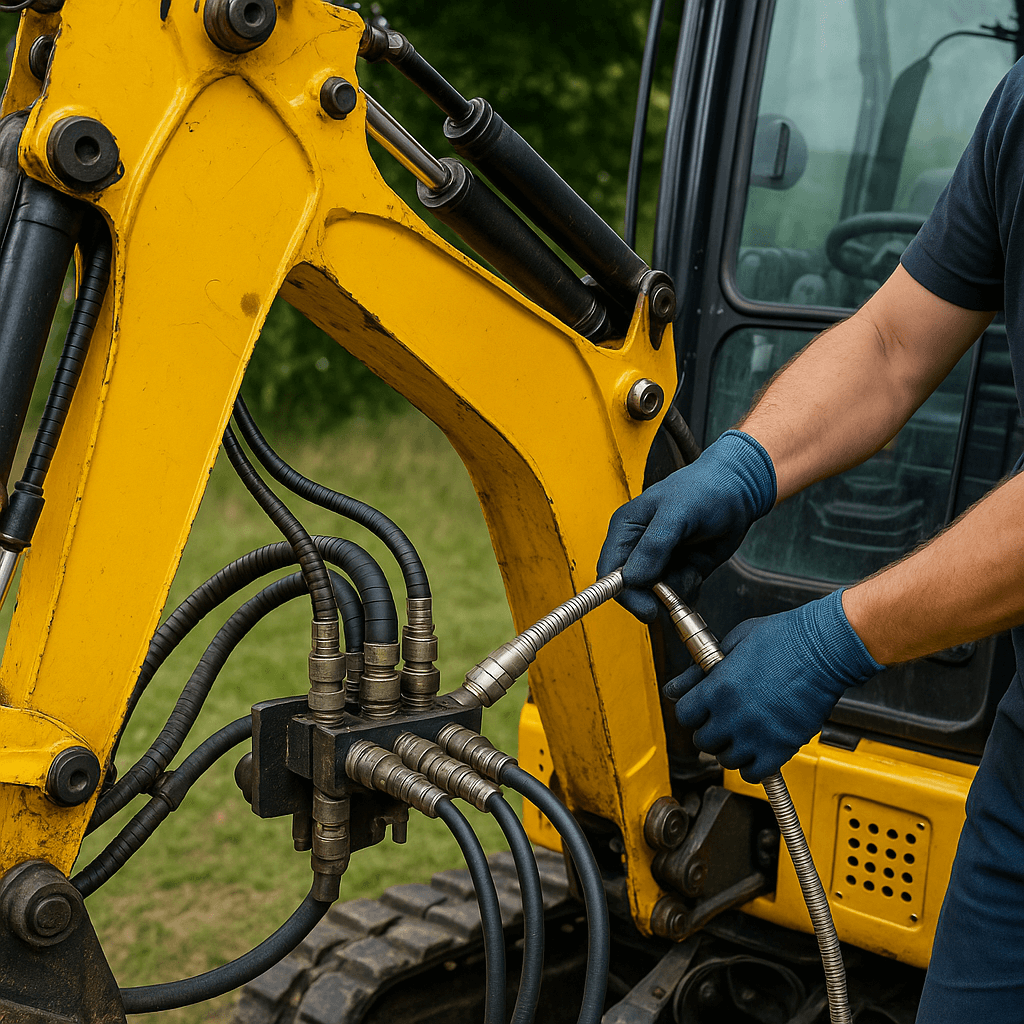

Consistently do a walk-around of your Skid Steer Attachments before placing them to grind. Pay close concentration to all hydraulic hoses to make sure there are no pinhole leaks. A leak can evolve into a very difficult situation for employees and can lead to costly restorations.

Visually examine your pins and bushings to guarantee they’re not worn. They take on a lot of pressure and the last thing you want is a broken pin or bushing while in the position. During your walk-around, look for noticeably open bolts, cap screws, and fittings, and ensure that all your security shields are securely in the zone. If you’re utilizing a chain-driven or bladed attachment, review your chain tension and set any tooth or blade wear.

4. Keep Clean

You can reasonably avoid missing worn or harmed components if your Skid Steer Attachments are sterile of all dirt and debris. At the back of a long day’s work, hit the attachment with a power washer, and determined to keep all the security decals neat and readable.

5. Store Wisely

Skid Steer Attachments are usually left outside where they’re exposed to the extreme elements. Occasionally an operator has no option. But, if you have the qualifications, make a habit of keeping your equipment in a cool, dry, protected place to maximize its lifespan.

6. Stay Safe

Our top priority is ensuring the safety of every customer.

Rule #1, if you’re performing any maintenance beyond daily inspections, always relieve the hydraulic pressure before you disconnect hoses or start wrenching. It’ll help prevent injury, downtime, and added cost. In addition, observe these suggestions to keep yourself and others guarded in the job zone or in the shop.

- Keep others 50 feet away when operating or fixing

- Review for debris in the mounting zone before each hook-up

- Double-check the attachment is appropriately mounted before operating

- Route hydraulic hoses properly between the lift arms and attachment to dodge hose pinch

- Never crashed or pound couplers

- Guarantee all equipment before transporting

- Always wear appropriate safety gear

Proper maintenance of your skid steer attachments is an investment in both productivity and cost savings. By regularly inspecting, cleaning, and storing your attachments properly, you can prevent damage, reduce downtime, and maximize their lifespan. Whether you’re using buckets, augers, or grapples, these six tips will help you get the most out of your equipment.