Mini excavators are versatile devices mostly used in agriculture, building, and gardening. Regarding grading, trenching, and excavation—their small size and adaptability make them ideal. Still, their ability is often limited without the right link.

Strong material handlers produced from heavy-duty Pallet Fork Attachments substantially enhance the mini excavator’s value. Here’s how heavy-duty pallet forks might optimize operations and project efficiency.

Prominence of Heavy Duty Pallet Fork Attachments:

Designed to quickly and safely handle material-lifting tasks, heavy-duty Pallet Fork Attachments are basic equipment for compact excavators. Usually constructed from reinforced, high-grade steel to support heavy weights like pallets, stones, and boulders, these forks Their robust structure provides reliability and helps workers to complete challenging tasks free from equipment failures.

Applications for heavy-duty pallet forks are quite important:

- Enhanced Efficiency: Reducing manual labor by enabling quick transportation of heavy commodities like mulch or dirt increases construction output.

- Versatility: Changing tine widths allows varying load sizes, therefore ensuring efficient and safe transportation of weirdly shaped items.

- Durability: These forks, intended to last in demanding surroundings, cut wear and tear on heavy-duty jobs.

- Improved Logistics: By streamlining material movement, simplify worksite logistics and hence reduce downtime and boost output.

Heavy-duty pallet forks are absolutely essential for professionals in gardening and construction to complete projects effectively.

Especially in landscaping projects, heavy-duty pallet prongs increase mini excavator capacity. They allow operators move large gardening equipment, stones, trees, and other hazardous or difficult by hand things.

How Might Sturdy Pallet Forks Improve Landscaping?

Heavy-duty pallet forks in your mini excavator tool set assist with many landscaping chores. These attachments demonstrate how effective lifting solutions increase work site efficiency and highlight the many equipment applications in contemporary landscaping by moving large rocks for natural features or by carefully regulating soil distribution.

Different Approaches for Strong Pallet Forks for Landscape Projects:

- Easy Material Handling: You save time and work by straight forwardly moving sod, mulch, and ornamental stones for landscaping jobs.

- Transporting Trees and Plants: Safely moving big trees and plants will assist to guarantee operator safety and stop damage of their roots.

- Placement Tactics: It helps in arranging stones, pebbles, or other objects precisely according to the garden aesthetics development.

- Simplified Operations: Move bulk goods from trucks to project sites—that will simplify logistics—such as fertilizers or soil bags.

- Reduced Labour Costs: Lowering the requirement for physical lifting and extra effort helps to lower the overall project expenditures.

These attachments streamline material handling and ensure perfect placement, therefore allowing landscapers to complete jobs faster and with greater accuracy.

Excellent Construction Material Management

Any work site’s performance may be improved with the help of heavy-duty pallet forks among construction efficiency equipment. Their enhancements make mini excavators safe, strong, and efficient. Premium pallet forks speed teams through tasks and improve material handling.

Benefits at construction sites:

- More Productivity: Move fast and forcefully large things such bricks, concrete blocks, and metal sheets.

- Improved Safety: Manual handling free from large loads helps to cut injuries.

- Automating material handling tasks will assist to reduce worker expenses.

- Enhanced Precision: Let operators accurately stack or arrange items to save waste and rework.

Including heavy-duty pallet forks into construction projects promises faster, safer, more reasonably priced material handling.

Restressing Safety

Safety is much improved by heavy-duty pallet forks versus hand lifting. Manual lifting could strain and sprain the muscles. Mini excavators with pallet forks help to reduce human mistake and physical strain whilst handling large quantities. Many times, builders manually carry big rebar bundles or brick pallets. This reduces safety and productivity as well. Strong pallet forks allow one to transport big things without compromising their safety.

Safety Issues with Pallet Forks:

- Training Operators: Make sure operators are tool competent and understand safety protocols.

- Load Limit Awareness: Following the fork’s weight limit helps to prevent overloading and disasters.

- Clear Communication: To avoid misunderstanding, employ hand signals and team collaboration all through lifting operations.

- Regular Maintenance: Correct issues straight immediately after fork wear and tear analysis including bent tines or weak connections.

- Stable Operation: Load correctly to stop shifting throughout travel.

Regular maintenance and safety-first consideration for operators determine both pallet fork lifetime and efficiency as well as reducing hazards.

Perfect Applications for Pallet Forks Designed for Heavy-Duty

Heavy-duty pallet forks would find ideal use for mini excavators used in construction and industry. These attachments help to ease the hauling of concrete blocks, bricks, and lumber on building sites. Using a compact excavator with pallet forks quick loading or unloading trucks saves time and improves efficiency. This function reduces downtime not like manual handling.

In agriculture, large crop shipments or hay bales need for heavy-duty pallet forks. Farmers may move big items around the farm or between fields with these attachments, therefore sparing staff members from overworking. Moving many bales simultaneously shortens the distance covered in transportation. Faster operations liberate farmers from concern on logistics to focus on planting and harvesting.

Practically speaking, using these attachments increases production. One operator can rapidly move large stones to build a pathway or garden feature using pallet forks instead of multiple workers lifting each stone.

Heavy-duty pallet forks boost efficiency in many kinds of operations and provide industry-specific solutions. These mini excavator attachments help you to securely do large lifting chores and increase performance.

The Popular Applications of Fork Attachments in Different Sectors:

- Construction Field: It is easy, quickly and efficient to transport concrete blocks, logs, and bricks.

- Agriculture: One can easily transport hay bales, crop shipments, and feed supplies.

- Landscape: It can accurately lift and arrange trees, boulders, and decorative stones.

- Warehouse Operations: Best usage to sort pallets and unload cars into storage locations.

- Road Maintenance: It is the flexible attachment for maintaining roads for paving, transportation, and construction.

These adaptable instruments help operators to do tasks faster and with less physical effort, therefore increasing output in many varied environments.

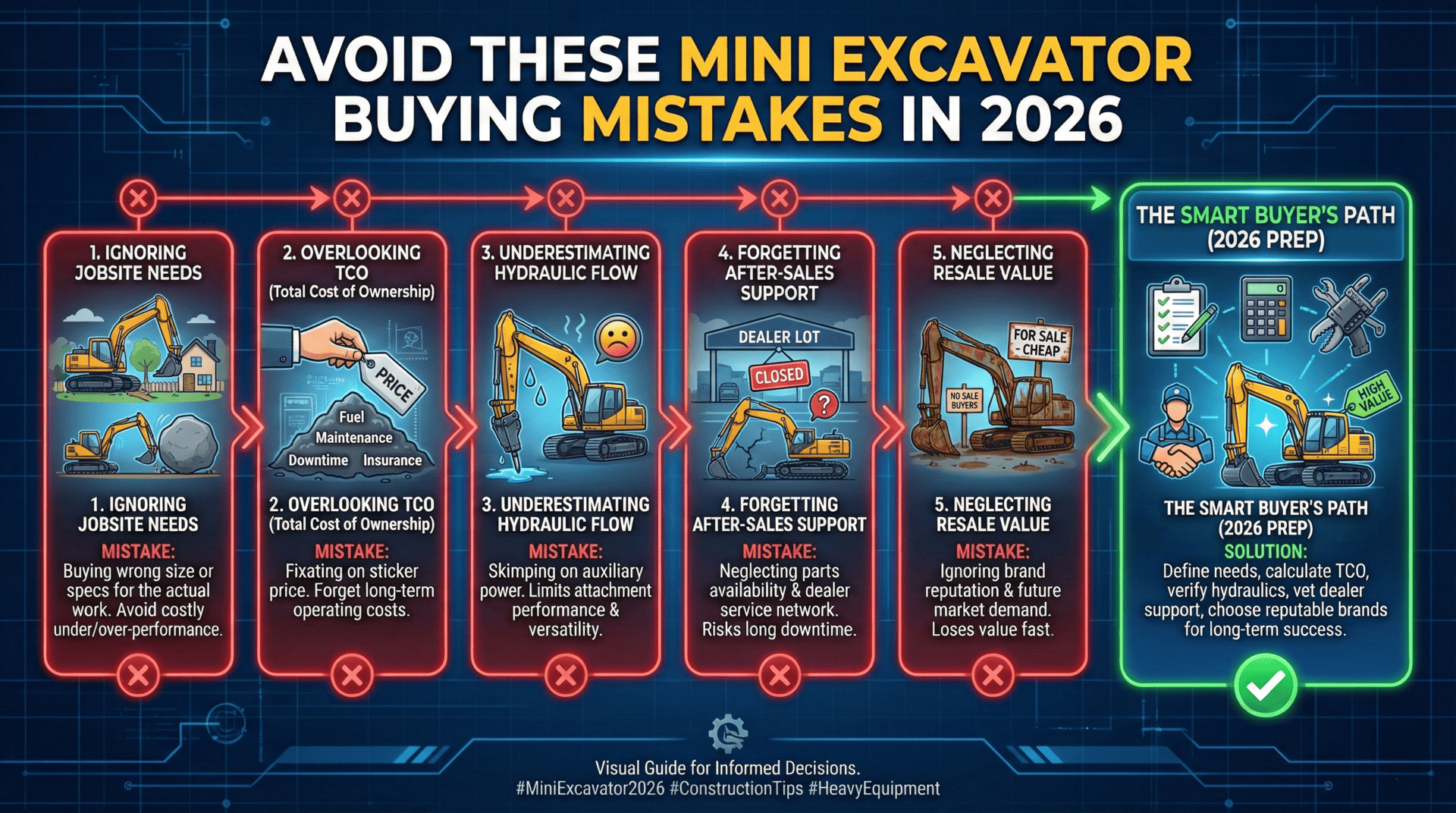

Selecting a Mini Excavator Pallet Forks

Choosing heavy-duty pallet forks for your mini excavator calls for careful weighing of several criteria. Evaluate first load capacity for your regular responsibilities. Selecting a fork capable of handling your most demanding uses guarantees best performance free from equipment damage or human safety hazards. For instance, pallet transporting large goods calls for more lifting capability.

Thought Through Elements: Consideration

- Load Capacity: Select forks fit for your biggest loads without sacrificing performance or safety.

- Compatibility: See if your excavator’s prongs fit either pin-on connection or fast coupler.

- Build Quality: Choose superior steel forks with durability and wear & tear resistance.

- Value vs. Cost: Balance initial costs with long-term benefits like less maintenance and more production.

- Brand Reputation: Choose forks from reputable manufacturers marked in reliability and quality.

Choosing the right pallet forks helps you to utilize your mini excavator and assures optimal performance.

Guideline for Durability Maintenance

Keeping heavy-duty pallet forks for mini excavators guarantees performance and lifetime. Typical maintenance jobs include regular cleaning, pivot point lubrication, and hydraulic connection checks. After usage, check forks for trash and dirt. Just a basic wash prevents corrosion and rust. The company asserts that lubricating moving components reduces wear. During maintenance, inspect for hydraulic line leaks.

Look for wear that calls for either replacement or repair. Safety and efficiency might be compromised at hinge points by cracked tines or too much play. Check your forks if they twist or bend when you raise. Regularly check connection points and welds; heavy-duty work might strain them.

Good storage helps heavy-duty pallet forks last as intended. Keep them dry to avoid corrosion even in non-use. Covering stored outside or moved between-work site forks helps protect them from dust and corrosion. Hang forks straight on shelves or vertical racks if at all feasible to prevent missed inspections or bending.

Maximizing the heavy-duty pallet fork performance with a mini excavator depends on maintenance. Adhering to proper maintenance and storage practices ensures the longevity and reliability of your instruments. Robust tools may facilitate project completion and reduce replacement and maintenance costs.

Mini Excavator with Fork Attachments

For your mini excavator, investing in heavy-duty pallet forks improves its efficiency, adaptability, and output. From landscaping and construction to agricultural operations, these attachments let operators to easily manage a broad spectrum of activities.

By selecting the right pallet forks and maintaining them properly, you can maximise your mini excavator’s potential, reduce manual labour, and achieve outstanding results in all types of projects. Upgrade your mini excavator with heavy-duty pallet forks today to experience unmatched performance and efficiency.