The Definitive Guide to Mini Excavator Specifications: Decoding Weight, Power, and Capacity

In the heavy equipment industry, the spec sheet often determines whether a project is profitable or a logistical challenge. For contractors, landscapers, and fleet managers, a mini excavator serves as an indispensable tool on the job site. But “mini” is a deceptive term. This category ranges from 2,000-pound micro-machines that fit through doorways to 20,000-pound powerhouses that rival full-sized earthmovers.

Choosing the right machine requires more than just kicking the tracks. It requires a granular understanding of how specifications translate to real-world performance. A machine with high horsepower might have weak breakout force. A unit with impressive digging depth might lack the stability to lift a concrete pipe safely.

This guide moves beyond the glossy brochure highlights. We are going to dissect the five critical pillars of excavator specifications—Weight, Size, Engine Power, Digging Geometry, and Operating Capacity—to ensure your next equipment investment delivers maximum ROI (Return on Investment).

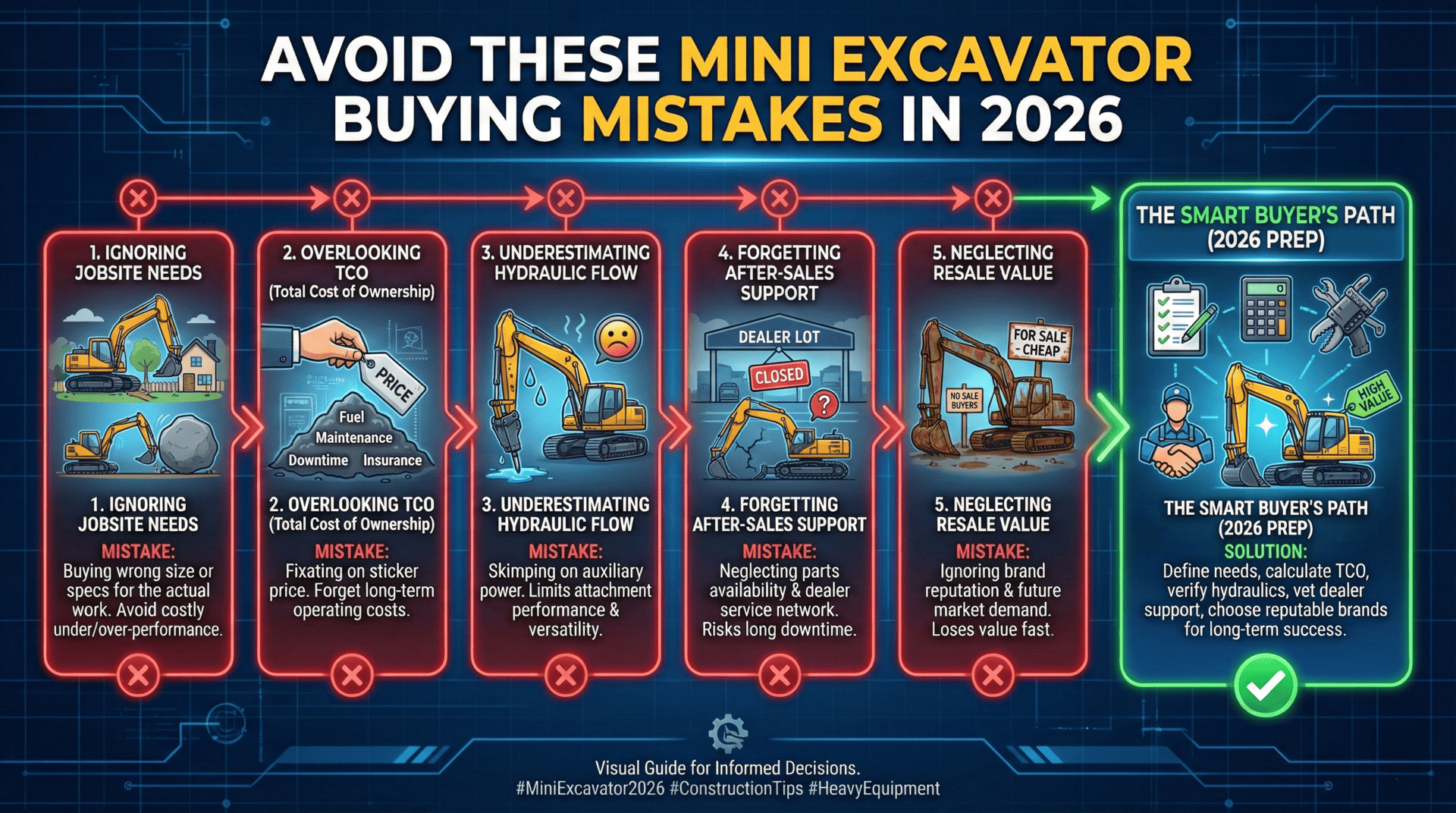

1. Operating Weight: The Anchor of Your Fleet

Operating weight is the most fundamental specification of any excavator. It doesn’t just define the machine’s class; it dictates your logistics, your legal transport requirements, and the surfaces you can work on.

The Classification Spectrum

While manufacturers group machines differently, the industry generally adheres to three main weight classes within the compact sector:

- The Micro Class (0–2 Tons): These machines typically weigh between 2,000 and 4,000 lbs.

- Application: Indoor demolition, residential backyard renovation, and irrigation installation.

- The Advantage: Ultra-low ground pressure. They can cross manicured lawns with minimal turf damage, reducing restoration costs.

- The Utility Class (3–5 Tons): The 6,000 to 11,000 lb range represents the industry’s optimal performance.

- Application: Utility trenching, septic systems, footings, and pool excavation.

- The Advantage: A perfect balance of breakout force and transportability. This is the rental yard favorite for a reason.

- The Midi Class (6–10 Tons): Weighing 12,000 to 20,000 lbs.

- Application: Heavy highway work, commercial site prep, and demolition.

- The Advantage: These offer the cabin comfort and digging power of a large excavator but can still operate in a single lane of traffic.

The Logistics of Weight: Transport and Towing

Operating weight is arguably more critical for getting to the job than doing the job. A common mistake new owner-operators make is buying a machine their current truck cannot legally tow.

- The GCWR Trap: You must calculate the Gross Combined Weight Rating. The combined weight of a 10,000 lb excavator and a 3,500 lb heavy-duty trailer comes to 13,500 lbs. This figure exceeds the towing capacity of many half-ton pickups. You are likely moving into ¾-ton or 1-ton truck territory (Ford F-250/350, Chevy 2500/3500).

- CDL Requirements: Once your Gross Vehicle Weight Rating (GVWR) of the truck/trailer combo exceeds 26,000 lbs, you may need a Commercial Driver’s License (CDL), depending on local regulations. Jumping from a 5-ton to an 8-ton excavator often triggers this legal threshold, drastically changing your operational costs.

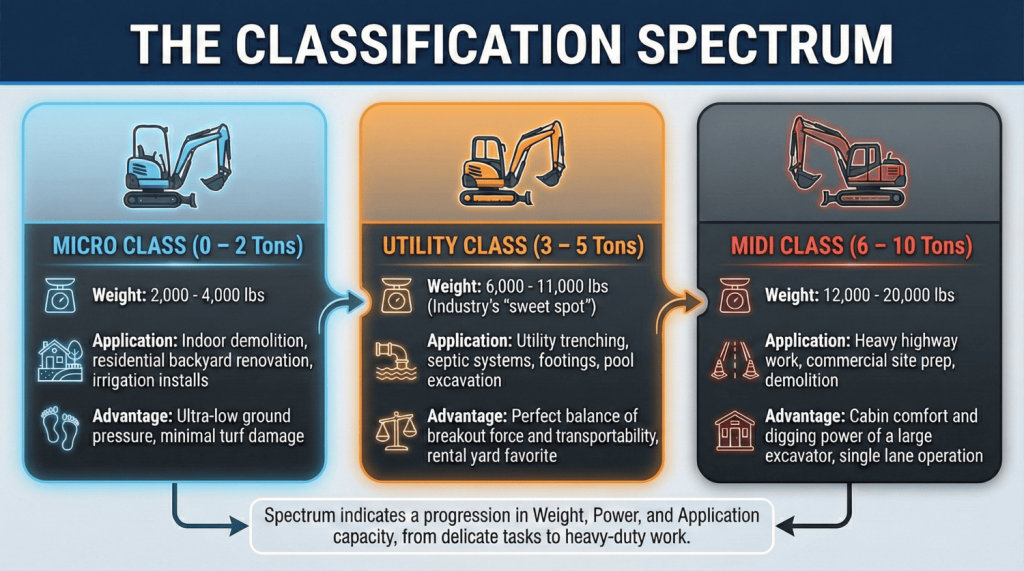

2. Size and Dimensions: Access is Everything

Power is useless if the machine physically cannot fit into the workspace. When analyzing dimensions, you need to look at three specific metrics: track width, transport height, and swing radius.

Variable vs. Fixed Undercarriage

For the micro class (under 2 tons), look for a retractable undercarriage.

- Retracted: The tracks pull in hydraulically (often to roughly 28-39 inches), allowing the machine to drive through a standard residential garden gate or a commercial doorway.

- Extended: Once on the dig site, the tracks expand to their full width to provide the necessary stability for lifting and swinging.

For larger machines (3+ tons), tracks are fixed. You must measure the narrowest point of access on your typical job sites. If you work primarily in urban alleyways or between property lines, a 4-ton machine might be too wide, forcing you to downsize to a 3.5-ton unit.

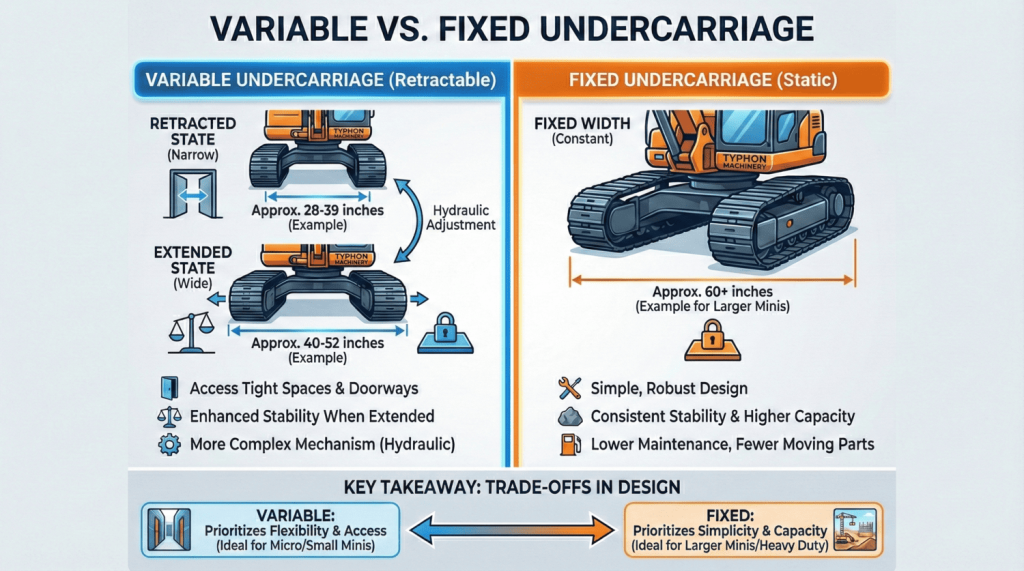

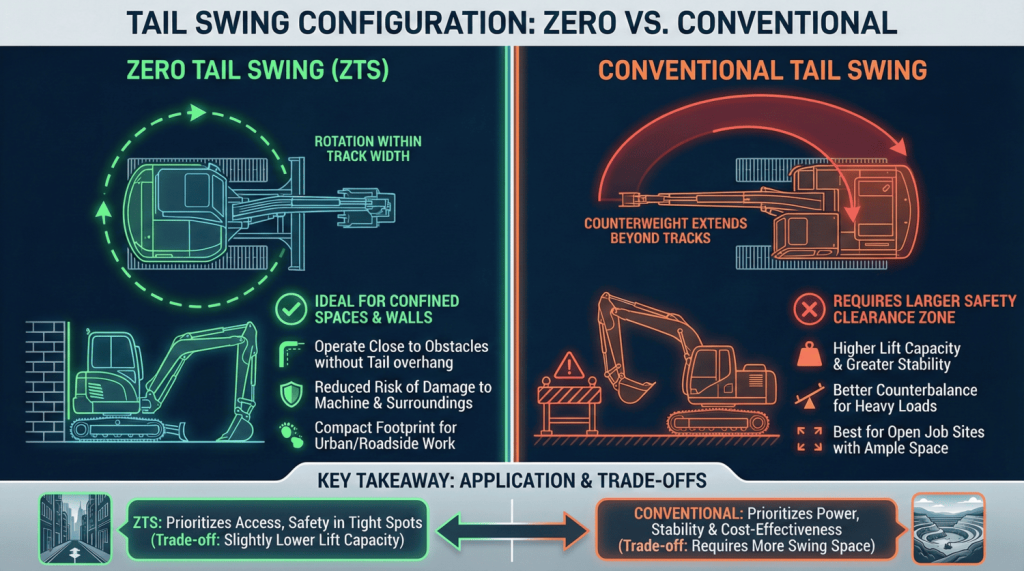

Tail Swing Configuration

This is a critical design choice that impacts both safety and capacity.

Conventional Tail Swing: The rear counterweight extends significantly beyond the width of the tracks when the house rotates.

- Pros: Physics favors this design. The further back the weight is, the more leverage (and lift capacity) you have.

- Cons: High risk of collision. If you are digging next to a wall or a parked car, the operator must be hyper-aware of the rear end to avoid swinging into obstacles.

Zero Tail Swing (ZTS): The house rotates within the footprint of the tracks.

- Pros: Peace of mind. You can park the machine right against a foundation wall and rotate 360 degrees without hitting the building. This ability is essential for highway work (working within one lane) or residential tight spots.

- Cons: To keep the weight inside the tracks, engineers often have to sacrifice some lift capacity or make the cab slightly more cramped.

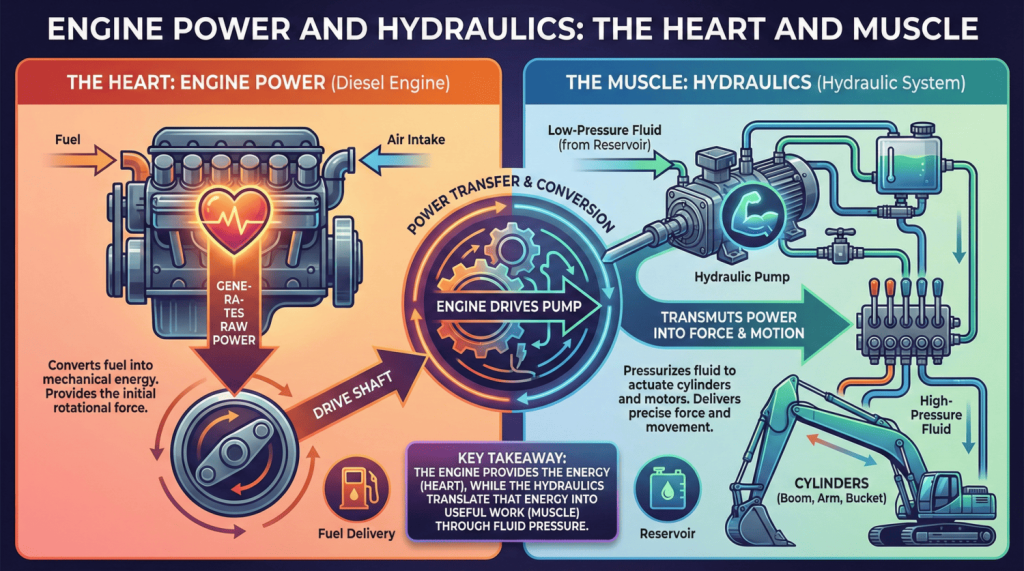

3. Engine Power and Hydraulics: The Heart and Muscle

There is a pervasive myth in the industry: More horsepower = better machine. This is false. In excavation, the engine is just the generator; the hydraulic system is the muscle.

Horsepower (HP) vs. Torque

While you generally want a diesel engine (like a Kubota, Yanmar, or Perkins) that offers reliable torque, the HP number is often regulated by emissions tiers.

- The 25 HP Threshold: In many regions (like the US and parts of Europe), engines under 25 HP are subject to fewer emission regulations (no DPF or DEF fluid required). Many manufacturers tune their 3-ton machines to exactly 24.8 HP to avoid complex emission systems, keeping maintenance costs low for the owner.

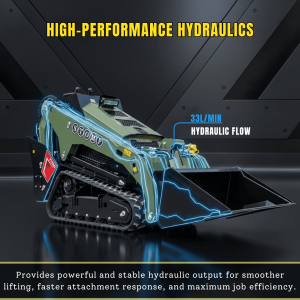

Hydraulic Flow: The Real Metric

If you plan to use attachments—which you should, to maximize income—you need to look at Auxiliary Hydraulic Flow, measured in Gallons Per Minute (GPM) or Liters Per Minute (LPM).

- Standard Flow: Sufficient for buckets and thumbs.

- High Flow: Essential for active attachments like brush cutters (mulchers), augers, and cold planers.

- Example: A 35 HP machine with a hydraulic flow of 15 GPM will outperform a 45 HP machine with only 10 GPM when running a hydraulic breaker. The engine power means nothing if the hydraulic pump cannot deliver the fluid fast enough.

System Pressure (PSI)

Flow is the speed; pressure is the strength. High system pressure (often 3,000+ PSI) gives you the breakout force. This is the power available at the bucket teeth to curl and tear through hardpan soil, clay, or roots. Always compare the Bucket Breakout Force” and “Arm Breakout Force” on the spec sheet.

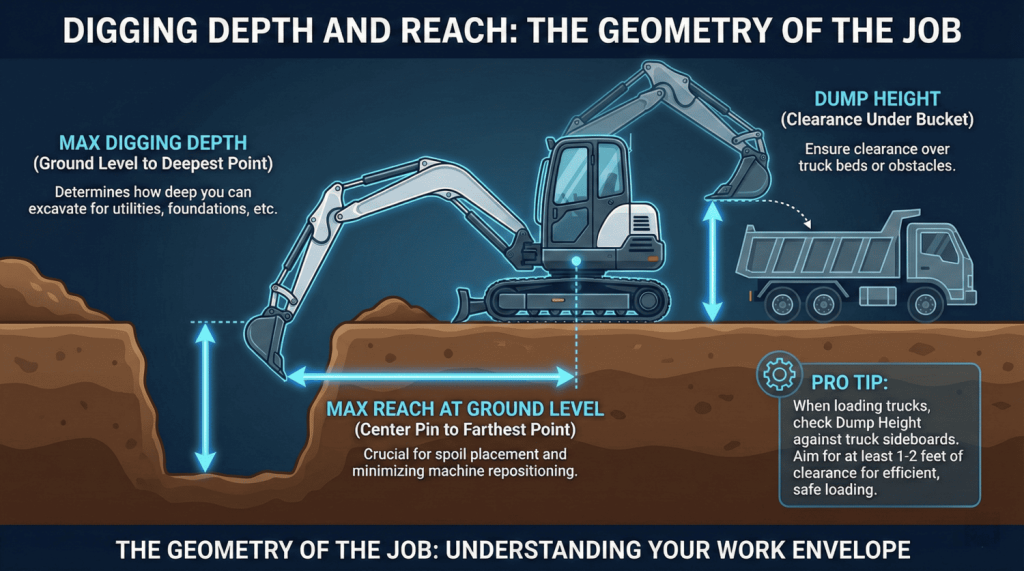

4. Digging Depth and Reach: The Geometry of the Job

Digging specs define the “box” you can work within. However, maximums can be misleading.

Maximum Digging Depth

This is the standard measurement from ground level to the bucket teeth at the lowest point.

- The Trap: Buying a machine that just reaches your required depth. If you routinely dig 10-foot sewer trenches, do not buy a machine with a max depth of 10’2”. You will be operating constantly at full extension, which is inefficient and unstable. You should choose a machine that can reach 12 feet, allowing you to dig the 10-foot trench comfortably while keeping the boom in a power position.

Reach at Ground Level

This spec is often more valuable than depth. Reach determines:

- Spoil Placement: How far away can you dump the dirt? If your reach is short, your spoil pile will be right on the edge of your trench, increasing the risk of cave-ins and forcing you to handle the material twice.

- Repositioning: A machine with a long reach requires less tracking back and forth. You can dig a longer section of trench from a single stationary position, saving time and reducing undercarriage wear.

Dump Height

This is the clearance under the bucket when the boom is fully raised.

- Critical Check: Measure the sideboards of the dump trucks you use. If you hire high-sided tri-axle dump trucks, a standard 3-ton mini excavator might struggle to clear the side of the truck bed. You may need to build a ramp (time-consuming) or upgrade to a 5-ton machine with superior dump height.

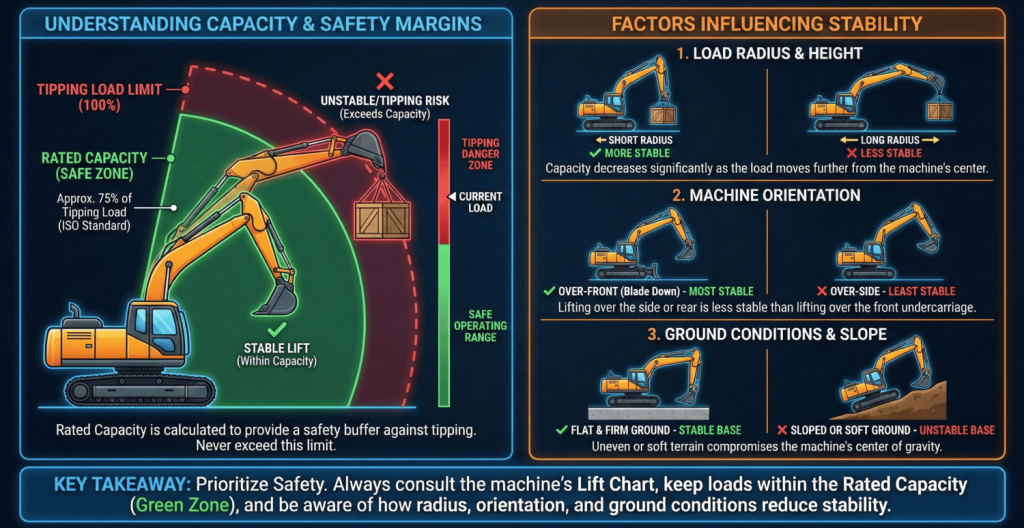

5. Operating Capacity: Safety and Stability

Of all the specifications, rated lift capacity is the one most likely to cause accidents if ignored.

Understanding the Lift Chart

Every reputable manufacturer provides a Lift Chart in the manual. This is a grid that shows how much the machine can lift at various heights and distances from the center pin.

- Over-Front vs. Over-Side: Excavators are shaped like rectangles, not squares. They are significantly more stable lifting over the front (especially with the dozer blade lowered as an anchor) than they are lifting over the side.

- The Fulcrum Effect: As you extend the arm further out, your lift capacity drops drastically. A machine that can lift 4,000 lbs close to the cab might only be able to lift 1,200 lbs at full reach.

Tipping Load vs. Rated Capacity

- Tipping Load: The weight at which the machine will physically tip over.

- Rated Capacity (ISO Standards): Safety regulations typically cap the Rated Capacity at 75% of the tipping load or 87% of the hydraulic lift capacity, whichever is lower.

- Pro Tip: Never push the machine to 100% of the tipping load. Soft ground conditions or a sudden hydraulic jerk can instantly turn a 95% load into a tipped-over machine.

The Unseen Specs

While the Big Five (Weight, Size, Power, Reach, Capacity) are the headlines, savvy buyers also check these often-overlooked details:

1. Boom Swing Angle

Can the boom swing independently of the house? Most mini excavators have a boom swing pedal that allows the boom to pivot left or right (usually 60-80 degrees). This option allows you to dig a trench parallel to the tracks right next to a foundation wall—a maneuver impossible for large excavators. Check the degree of swing; a higher angle equals more versatility in tight corners.

2. Serviceability Access

Open the rear hood. Can you reach the oil filter, fuel water separator, and air filter from the ground?

- Reality Check: If a mechanic has to remove panels or crawl under the machine to change a filter, maintenance will get skipped. Easy access translates to a longer machine lifespan.

3. Track Type (Rubber vs. Steel)

- Rubber Tracks: Standard for minis. They are quiet, don’t damage pavement, and provide a smoother ride.

- Steel Tracks: Available on larger minis (5+ tons). They provide superior traction in mud and jagged rock but will destroy driveways and curbs.

- Hybrid/Roadliner: Steel chains with bolt-on rubber pads. These chains offer the best of both worlds, providing durability and surface protection.

Conclusion: Matching the Machine to the Mission

Analyzing mini excavator specifications is an exercise in balancing constraints. There is no best machine—only the best machine for your specific constraints.

- If you work in tight residential backyards, prioritize retractable tracks and weight (for towing).

- If you do utility work, prioritize digging depth and breakout force.

- If you do land clearing, prioritize hydraulic flow (for mulchers) and cooling capacity.

Before finalizing the lease or making the payment, please review your last five projects. What was the limiting factor? Did you need more reach? Did you struggle to lift heavy catch basins? Was the machine too wide for the gate?

Use the specifications as your roadmap. By aligning the weight, size, power, digging geometry, and capacity with your daily reality, you ensure that your mini excavator becomes the most profitable employee on your payroll.

Frequently Asked Questions (FAQ)

Q: How do I know if I need a Zero Tail Swing (ZTS) machine?

A: If you frequently work in single-lane traffic closures or directly against residential structures, ZTS is highly recommended. However, be aware that ZTS machines can feel tippier over the side than conventional tail swing machines because the counterweight is tucked in closer to the center of rotation.

Q: Can I upgrade the counterweight on my mini excavator to lift more?

A: generally, no. While some manufacturers offer additional counterweight options, adding aftermarket weight without manufacturer approval can stress the slewing ring and undercarriage, potentially voiding your warranty and creating safety hazards.

Q: What is the difference between “Cab” and “Canopy” weights?

A: An enclosed cab with HVAC (heating and A/C) typically adds 300 to 600 lbs to the machine’s operating weight compared to an open ROPS canopy. Ensure you account for this extra weight when calculating your towing capacity.

Q: Why is the “Breakout Force” different for the Bucket and the Arm?

A: Bucket breakout force is generated by the bucket cylinder and is usually higher because it has a shorter lever arm. Arm (or Dipper) breakout force is generated by the boom cylinder pulling the whole arm toward the cab. When digging in hard ground, you typically curl the bucket (using maximum bucket force) to penetrate, then pull with the arm.

Q: Is a thumb attachment worth the extra weight?

A: Absolutely. A hydraulic thumb adds a small amount of weight to the end of the stick, which slightly reduces lift capacity, but it increases the machine’s versatility by 500%. It turns a digging machine into a material handling machine, capable of placing rocks, moving logs, and loading demolition debris efficiently