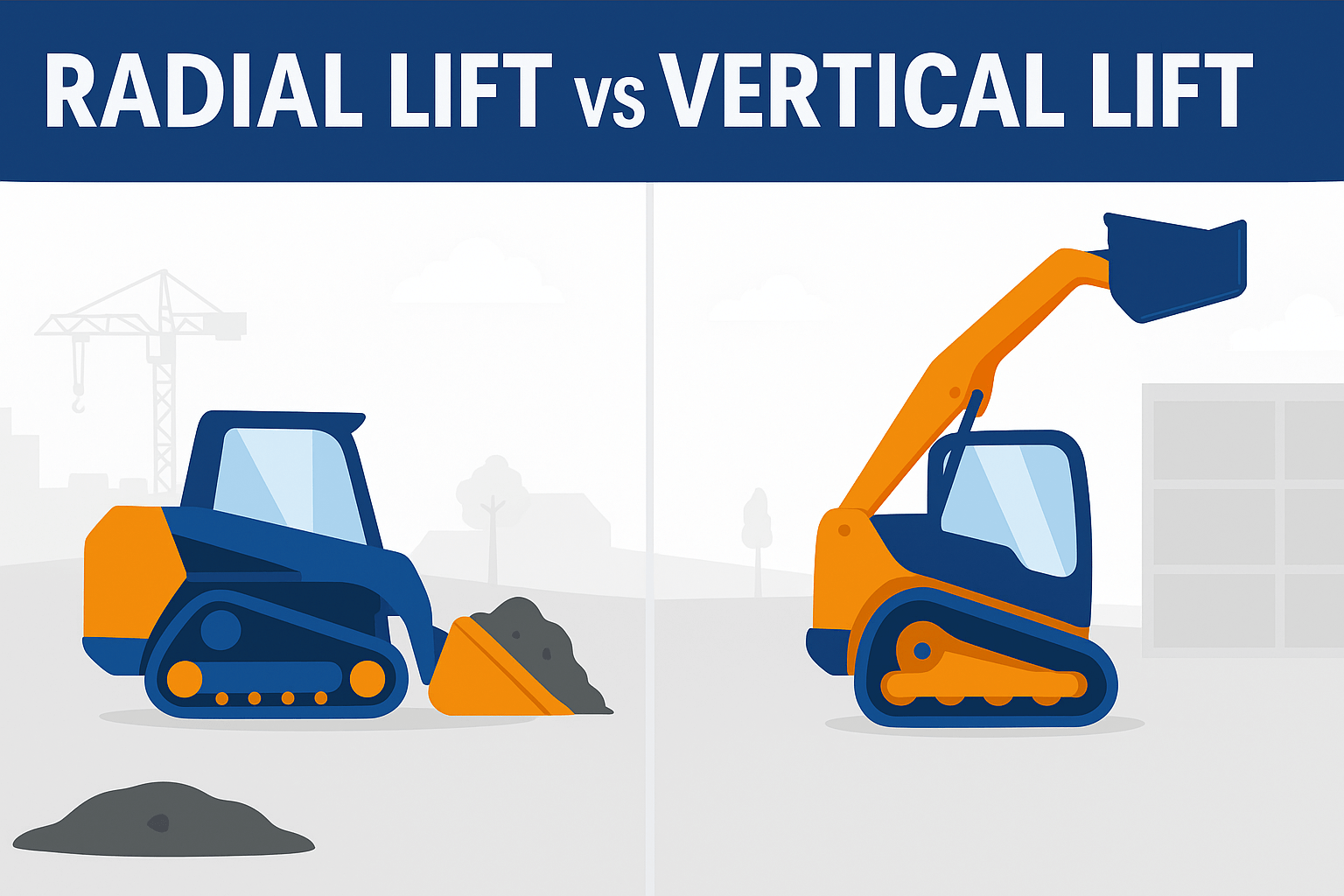

Radial Lift vs. Vertical Lift Skid Steer

Radial Lift vs. Vertical Lift Skid Steer, When looking for the perfect skid steer loader or compact track loader, you may select between a radial lift and a vertical lift. The distinction lies in the lift arm’s design and functioning.

Radial lift machines hoist weights along a curved route, whereas vertical lift machines move the lift arm straight up and down. Radial lifts feature a single pivot point, whereas vertical lifts have several, making them more complicated.

While both radial and vertical lifts may dig and raise materials, each is better suited to certain conditions and purposes. In this post, we’ll go over the fundamentals of radial and vertical lifts, including their similarities and distinctions, as well as how to select the best one for your next work.

Radial Lift Applications

The arm of a radial lift pivots at the back of the machine. It travels on an arcuate trajectory when elevated, extending both upwards and outwards. With the greatest reach at mid-range, a radial lift arm is ideal for jobs at or below eye level, making it an excellent choice for digging and grading.

Common usages and applications are

- Digging and excavation: A radial lift is capable of doing deep digging jobs such as trenching and excavation.

- Pushing materials: A radial lift may help clean a project site by removing debris such as boulders or stumps, as well as pushing materials like soil or snow.

- Loading materials: A radial lift can load and unload items such as soil or boulders onto or from vehicles or platforms.

- Backfilling, grading, and landscaping: A radial lift may backfill excavated areas, grade surfaces, and assist in the movement of landscaping materials.

Radial Lift Attachments

Specialized attachments increase the capacity of radial lift machines. Here are few typical attachments and their applications.

- General-purpose buckets: These attachments assist in digging, dozing, and ground-level material handling.

- Grapple buckets or grapple rakes: These attachments have more grip than standard buckets, making them ideal for jobs like brush removal, trash cleanup, or handling unevenly shaped things.

- Trenchers: These attachments let you excavate ground-level ditches.

- Mulchers or brush cutters: These attachments, known as mulchers or brush cutters, function to clear overgrown vegetation or in general land cleaning at or near ground level.

- Snow blades or snow blowers: These accessories increase the effectiveness of snow removal by building on a radial lift machine’s built-in pushing power.

- Landscape rakes or tillers: Tillers or landscape rakes: These tools support landscaping and ground preparation activities.

Vertical Lift Applications

A vertical lift’s more complicated connection mechanism lets the lift arm travel almost straight up and down. This offers more vertical reach than a radial lift would provide. Several pivot points offer more adaptability than a radial lift’s one pivot as well. For uses needing a greater reach, vertical lifts are ideal.

Typical usage and applications are:

- Material handling and stacking: A vertical lift machine’s vertical lift path allows it to handle and lift weights at great heights, making it useful for stacking.

- Loading high-sided vehicles: Similarly, vertical lift machines can load items into high-sided trucks such as dump trucks or onto elevated platforms without having to approach them.

- Drilling tasks: Vertical lift trucks may drill vertically into materials by attaching an auger.

Vertical Lift Attachments

Similar to radial lifts, vertical lifts are also capable of accommodating certain attachments. These are a few typical ones along with their uses:

- Material handling arms can improve grip and load capacity while lifting, putting, or stacking goods at large heights.

- Pallet forks: These attachments are designed specifically for handling pallets, making it easier to stack them or lift them to elevated areas.

- High-capacity buckets are designed to handle heavy or high-volume goods at height, such as when loading them into high-sided trucks or containers.

- Man platforms: These platforms are intended to elevate personnel performing duties like as maintenance, trimming, or painting.

Augers: As previously stated, these attachments aid in drilling, particularly at elevated areas such as placing tall posts or poles.

Radial Lift vs. Vertical Lift

Radial lifts and vertical lifts are both good material handlers, but there are some significant distinctions. Consider these comparative factors to help you decide which equipment is ideal for your work.

The Vertical Reach of Vertical Lifts Is Greater

When it comes to height duties, vertical lifts are superior to radial lifts. The reason for this is their lift paths; vertical lift arms have greater reach at maximum height because they travel almost straight up and down instead of curving.

You may move or position things at height securely because the weight stays close to the machine as it rises and falls, keeping it level and steady throughout the lifting operation.

At mid-range heights, radial lifts have a greater forward reach.

Radial lifts offer a greater forward reach than vertical lifts, especially at mid-range heights, even if they might not be able to reach as high.

Single pivot points at the back of the loader arm provide the basis for radial lift operation. You can reach farther forward as you raise your arm because it travels forth and upward. Radial lifts are therefore quite stable at mid-level elevations.

Vertical lifts include a more complex mechanical system.

Among the two machine types, vertical lifts are more complex. All working to achieve the smooth, steady up-and-down movement, its linkage system has several pivot points and interrelated bars or rods. As a whole, the machine is more stable and less prone to flip over even under increased weight or at higher altitudes.

Radial lifts have only one pivot point close to the back of the loading arm. It’s a simpler mechanical mechanism that causes the lift’s curving or upward and outward movement. However, while in operation, this mechanism can change the center of gravity of the load, hence compromising the stability of the machine as a whole.

Radial Lifts Are Typically Less Expensive

Radial lifts usually cost a bit less than vertical lifts as they are easier devices.

Still, rather than the one with the lowest cost, it is still crucial to select the machine that will best suit your task. In the long run, trying to operate with a machine that cannot perform what you want might be more costly both in terms of your time and the need to change tools.

Vertical Lifts Offer More Stability

Vertical lifts provide additional stability because of its vertical lift route and greater load capacity. This is particularly true if you are operating at considerable heights.

Although radial lifts are stable at mid-range heights, their lift arms’ forward extension can occasionally disturb the center of gravity of a load.

Vertical Lifts Require More Maintenance

Vertical lifts require greater maintenance due to their more complicated setups. To maintain a vertical lift working properly, the sophisticated linkage system requires more regular checks and necessary changes. Furthermore, the intricacy of vertical lifts may need specific training or knowledge for maintenance, potentially influencing long-term maintenance costs.

Radial lifts, on the other hand, have fewer components to wear out or repair due to their single pivot point design. This might lead to decreased long-term maintenance expenses.

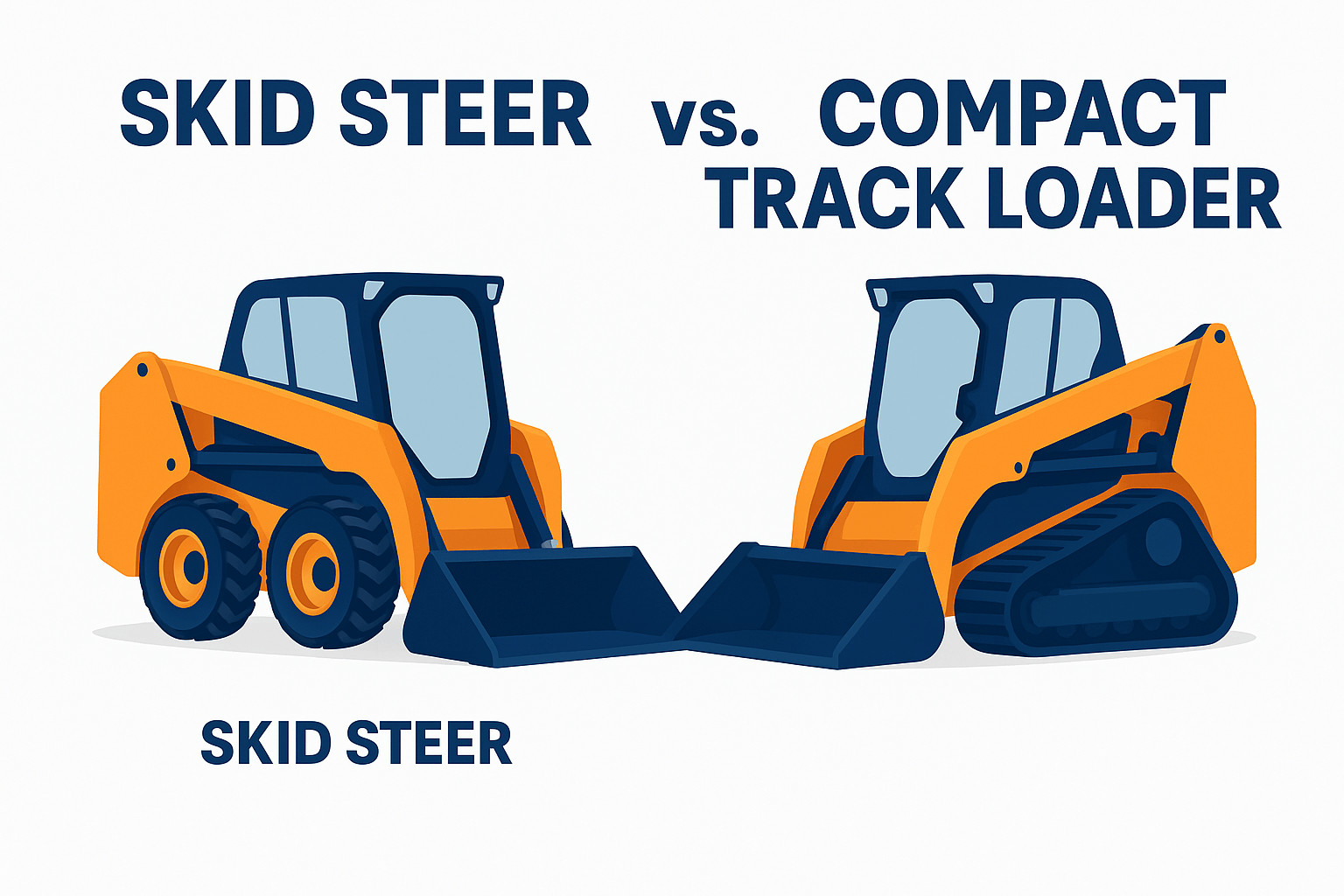

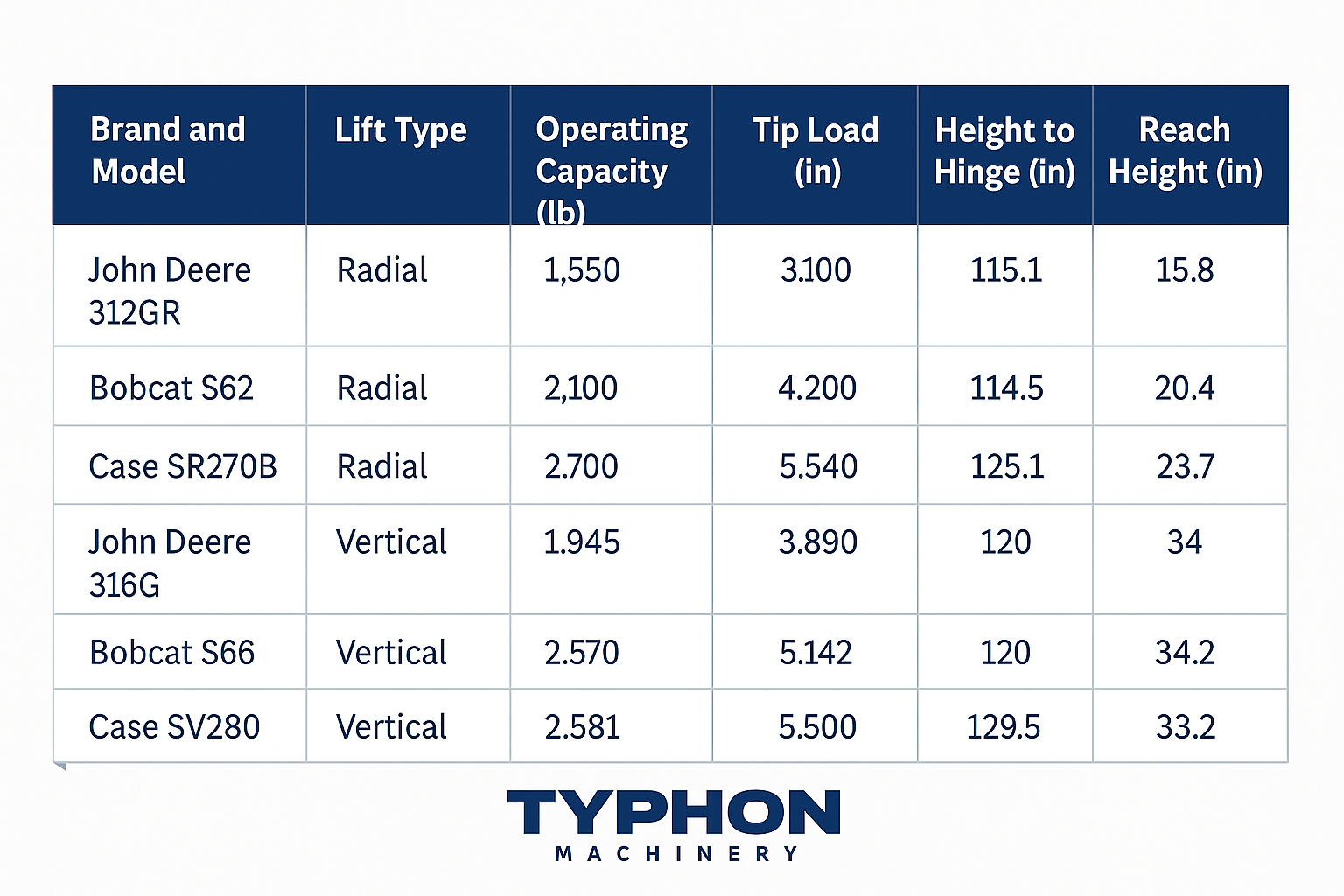

Radial vs. Vertical Lift Skid Steer Specs

Skid steers are wheel-based equipment that work well on hard surfaces such as asphalt, concrete, and compacted dirt. They work best on very level ground and in dry circumstances.

Whether you’re searching for a radial lift or a vertical lift skid steer, there are a few crucial skid steer specifications to bear in mind:

- Operating capacity: This refers to how much weight the machine can safely lift or carry. Make sure the skid steer you select has the operational capability to accommodate the weight of your cargo.

- Tipping load: The amount of weight that might cause the machine to tip—essentially its maximum capacity. Knowing this quantity helps you avoid overloading the machine and tipovers.

- Raise height: This is the highest height that a loader can raise. Make sure your equipment has the necessary lift height for your project, especially if you’re operating at a height.

Here’s an overview of skid steer specs for some popular brands and models.

Radial vs. Vertical Track Loader Specs

A small track loader is a form of skid steer. Track loaders use continuous tracks instead of wheels, which allows them to work over soft or muddy ground, snowy or damp conditions, and difficult or uneven terrain.

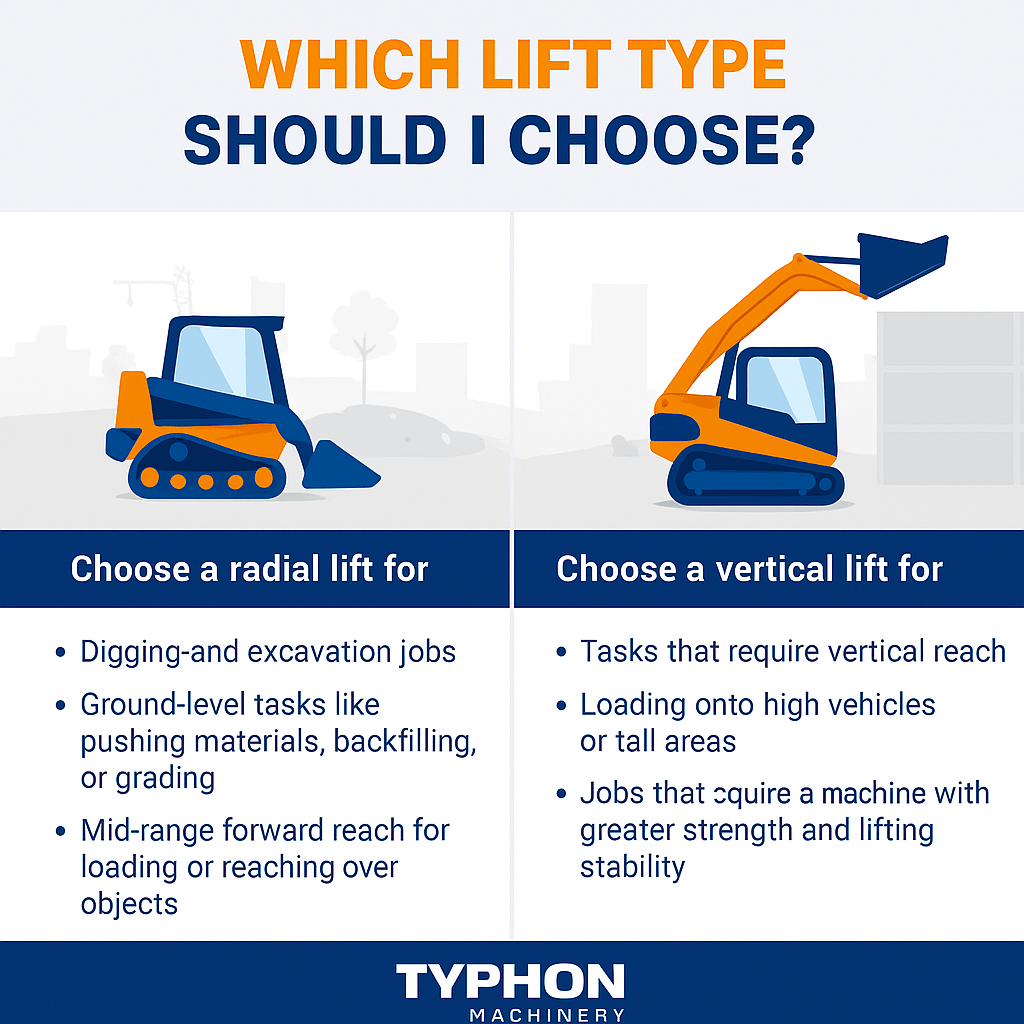

Which Lift Type Should I Choose?

Radial lifts and vertical lifts can be useful in a variety of material handling applications. The ideal skid steer for your work will be the one that best meets your project’s unique requirements.

When to Choose Radial Lift

If your project includes duties like:

- Digging and excavation jobs

- Mostly ground-level chores.

- Mid-range forward reach to load things or reach over obstacles.

When to Choose Vertical Lift

You may choose to choose a vertical lift if your projects have the following needs:

- Vertical Reach is necessary.

- Loading into high trucks or towering places

- You require a machine with increased strength and lifting stability.