Skid steer loaders are used on construction sites of all sizes because they can execute a wide range of earthmoving activities, including excavating, landscaping, and rubbish disposal. There are two major categories to consider: wheeled skid steers and compact track loaders.

Skid steers and small track loaders serve similar roles and can be used interchangeably. What’s the main difference? Skid steers have wheels, whereas track loaders travel on tracks. The type you pick can have a big influence on the success of your project, so you should learn which jobs each one is best suited for.

To assist you determine whether a skid steer or track loader is right for your next job, we’ll go over how each operates and the significant distinctions between the skid steer vs compact track.

What Is a Wheeled Skid Steer?

A wheeled skid steer is a small equipment intended mostly for excavating and landscaping tasks. It has four wheels and two arms that may connect to a variety of accessories, such as buckets, snowblowers, and pallet forks. Because the wheels are attached to locking axles, the skid steer operator must accelerate the wheels on one side to steer the machine.

Used for little excavating and gardening projects.

What Is a Compact Track Loader?

A compact track loader is a skid steer that operates on two parallel tracks rather than wheels. These machines are comparable in size to skid steers and perform many of the same activities, but greater weight and increased traction allow them to travel more easily across slick or uneven terrain. Track loaders are available in a range of sizes and may be used for earthmoving, excavation, and demolition.

Used for earthmoving applications that require higher traction and stability.

Key Differences Between Wheeled Skid Steers and Track loaders

Skid steers and compact track loaders have many similarities, but they also have unique characteristics and capabilities that distinguish them. To know the difference among steer vs compact track loader, the following elements should be carefully considered while selecting the correct loader for your project.

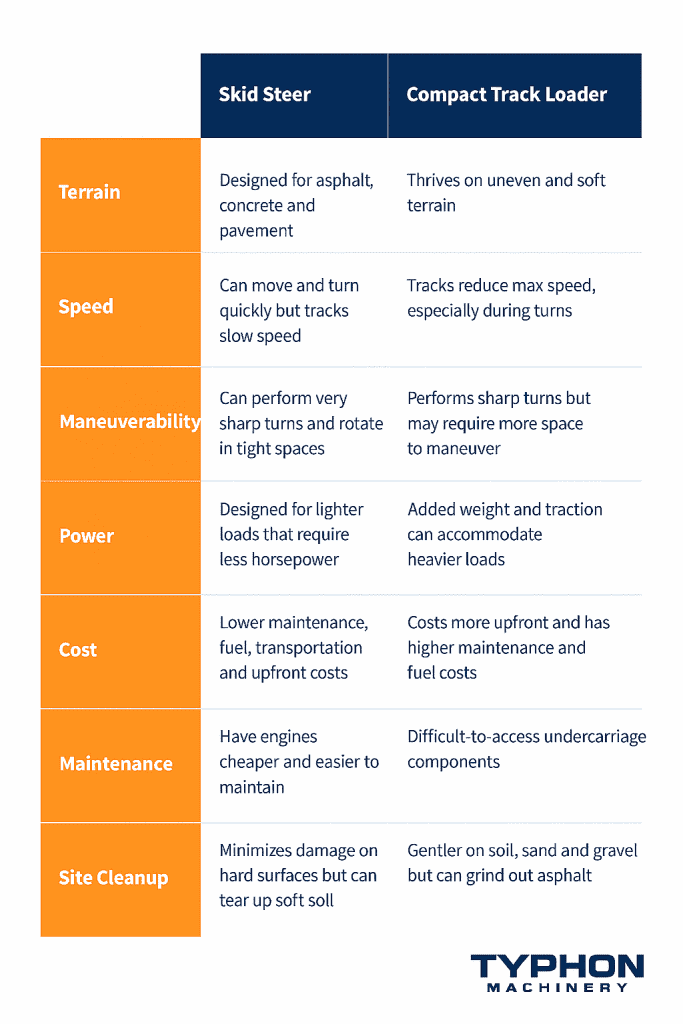

Terrain

Skid Steer

Skid steers with wheels excel on hard, flat terrain. If your job site is on concrete, asphalt, or another built surface, a skid steer is probably the best option. Wheels are less prone to harm these surfaces and allow the machine to travel fast on level terrain. However, wheels do not perform well on snow or damp conditions, so you may need to install winter tires or wait for the site to try if the ground is slick.

Track Loader

Compact track loaders are better suited for undeveloped land, uneven terrain, and damp or slippery job sites. Whereas a skid steer may sink into sand or mud, a track loader will remain steady. This is because the tracks uniformly distribute the machine’s weight and provide extra traction to avoid slippage.

Speed

Skid Steer

If you need a fast-moving machine, a skid steer is probably the best option. Skid steers are lightweight and have no slow-moving tracks, letting them to move significantly quicker than track loaders on flat ground. They are also more suited to making tight bends and navigating busy worksites in less time.

Track Loader

Track loaders may not travel as swiftly as skid steers, therefore operations that require driving back and forth over vast distances may take longer to perform. This is often not an issue for lengthier projects or localized jobs, but it should be considered for initiatives with a tight deadline. A track loader, on the other hand, will result in less project delays when working on uneven terrain.

Maneuverability

Skid Steer

Skid steers can perform exceptionally sharp turns and spin almost in place, making them ideal for maneuvering in small locations. If you have a busy job site or little place to work, a tiny skid steer is an excellent choice.

Track Loader

Because track loaders function on fixed axles, they have similar turning capabilities as wheeled skid steers. They are often bigger and travel slower than skid steers, therefore they may not perform as well in confined places. Three-point rotations are also advised for these machines to save track wear.

Power

Skid Steer

Skid steers are lighter, having a greater center of gravity than track loaders. Larger machines can still carry hefty loads, although they may have a lesser weight capability than tracked models. Their diminished traction may also make pushing high-resistance materials more challenging.

Track Loader

Tracks improve weight distribution and increase touch with the ground. This permits track loaders to lift and push more weight without sliding. Some small track loaders have more horsepower than skid steers with wheels, making them more suitable for high-power operations.

Cost

Skid Steer

The cost of renting or purchasing a skid steer varies by area and manufacturer, although ones with wheels are often less expensive upfront and easier to maintain than track loaders. Skid steers, with their lightweight construction and smaller engines, can help save on gasoline and shipping expenses.

Track Loader

Compact track loaders are often more expensive to purchase or hire outright, and damaged tracks are more expensive to replace than tires. If you decide to buy a track loader for your project, you should allow for additional maintenance and damage expenditures.

Maintenance

Skid Steer

If you want an equipment that is simple to maintain, a skid steer is the perfect solution. Skid steers require less regular maintenance than track loaders, and if something goes wrong, the pieces are considerably easier to repair. Wheels also make cleaning and examining the undercarriage easier, which is useful for teams with a tight timetable.

Track Loader

Because track loaders’ tracks can nearly fully cover the undercarriage, cleaning and maintenance will take more time. This may be a difficult process for one-time projects or those with limited finances, therefore many project owners prefer to rent rather than own a skid steer to avoid spending extra time and money on upkeep.

Site Cleanup

Skid Steer

While a machine’s skills are crucial, you should also examine how it impacts the site once the task is over. Tires are often kinder on hard surfaces like as concrete and asphalt, whereas tracks can harm them. If your project needs you to operate on certain surfaces, using a skid steer can help you avoid having to repair surface damage later.

Track Loader

Using a track loader makes it simpler to minimize damage to grass and other soft surfaces. Track loaders, unlike wheeled skid steers, do not rip up the ground or leave large ruts behind because their tracks are level and uniformly distribute the weight of the machine. While track loaders might harm hard surfaces, they will save you time when cleaning up after landscaping projects.

Before you buy or rent a skid steer loader, be sure you know which type is appropriate for your job by learning the difference between skid steers vs track loaders. Skid steers with wheels are a cost-effective option for modest operations on level surfaces, but compact track loaders flourish on uneven terrain and work locations that demand a little additional force.