The Definitive Guide to Buying Mini Excavators: All You Need to Consider

If you are thinking of buying a mini excavator, first you have to consider if you are a veteran contractor or you are just like a new one who only get into a landscaping project. You need to get the right type of equipment since they can make a great difference in any kind of project. Compact and powerful mini-excavators are well known for the fact that they can work in very tight spaces and they are very versatile and efficient. However, the number of machines and the features are plenty of which will make you confused when it comes to your choice. So the question is, how do you select from the variety of options and features? Are you supposed to buy new or used ones?

What is the brand that will deliver the most satisfying service?

We have a solution to your problems, without any further ado we present you the guide on this website that deciphers the mystery of mini excavators by discussing their decisive features and through that provision you will certainly not be misled while doing the job.

Getting to Know Mini Excavators

What Are Mini Excavators and Their General Use

Mini excavators are small, but they are powerful machines used for digging and earthmoving. Not only are they the most suitable for places where larger machines cannot possibly fit in but also for construction and landscaping the compact design of these machines is still as powerful as the big ones. With the models that are in use, the weight varies, for the range of 3,000 up to 18,000 pounds, and regardless of the chosen model the attachments will partially decide that.

The Summary of the Tasks and Best Solutions

Excavators in the mini-size category are professionals in operations such as ditch digging, backfill placement, and building destruction. On a project that involves the creation of a foundation, in a limited space, the mini-excavator loader can go around tight areas or avoid trees and old structures with ease as well as the mini loader. The machines can also be used for the purposes of an excavation job and the installation work of a pool or decoration of a garden.

The diversification of the functions happens with the helpers the excavators get like the pans, brushes, etc.

Market Growth and Demands

Construction Briefing writes that mini excavators are at the forefront of the market’s newest trends. One of their key advantages is the fact that their very compact size makes it possible for them to be used in a wide range of small and large scale works. This expansion of the construction equipment sector is primarily driven by a customer base that consists of professionals and DIY enthusiasts who are looking for compact and work-dedicated solutions in limited spaces.

Comparison with Standard Excavators

When it comes to standard excavators, these are far bigger machines generally used in heavy construction. Standard excavators, by their very nature, are unsuited for limited spaces due to their size. On the other hand, mini excavators are easier to maneuver and can cope with even the smallest of details. In situations such as the one described above, where you may have a backyard or be in a city with little space, a mini excavator is ideal for you. Though they may have less power and capacity, this lack is compensated for by their use in challenging circumstances.

Key Features to Consider When Buying a Mini Excavator

Selecting your mini excavator requires a very accurate choice. We will explain to you the most significant features that you need to examine.

Size and Weight Considerations

First of all, check the map and find the place where you are going to use the excavator. In case your work site is limited in space, it’s better to choose a small-sized model. The weight range of mini excavators usually fluctuates between 3,000 and 18,000 pounds. For instance, the Bobcat E50 weighs approximately 5,000 pounds thus, it is suitable for small residential landscape projects or downtown areas with very small space.

Engine Power and Efficiency

Branded as an excavator without a heart-exposed engine. So, check if it has enough power and work with it. If you need the one for general construction, then find no less than 25 horsepower. The CATERPILLAR 301.8 of 25 HP is an example of a machine that offers decent energy at the same time that it does well in jobs of mild to moderate complexity. It is a common thing that a higher number of horsepower will bring the needed performance but it may also mean that a more expensive energy fuel will be consumed.

Hydraulic Systems and Controls

Hydraulic systems are the lifeblood of any excavator. The system provides the necessary energy to the tools and drives the action smoothly. With the help of an excavator with variable controls and automatic flow regulation, one can do the job efficiently and save a great deal of fuel. In fact, this method is the most precise and saves a lot of tasks, time, and money.

Attachment Compatibility

What makes mini-excavators appealing is the variety of attachments they can work with. This attribute imbues them with the capability to be the jack-of-all-trades. A bucket can be used for the operation of digging, an auger can be used for drilling etc. As one can work with a plethora of fittings and attach them according to the requirements, this job becomes much quicker. Quick hitches from companies like Komatsu define a new standard of performance by simplifying the attachment replacement process and increasing the overall efficiency of the task. This can mean that your projects go faster.

Practice these key aspects you get yourself a golden deal. Here are some steps to finding the perfect mini-excavator that suits your requirements and budget.

If you can’t decide the right choice for you, you might as well take some time to try out the various models of mini-excavators. Eventually, you will notice that one of them feels better to work with during the execution of your projects.

Leading Brands in the Mini Excavator Market

It’s clear that with their relatively small size, mini-excavators are the best friend of any contractor who is frequently working in confined spaces. Nevertheless, the concern about which product is the most reliable always prevails. Although there are just a couple of names in the contracting sector, it is still necessary to do a deep dive into the details of these names.

Caterpillar Mini Excavators

Caterpillar, also known popularly as CAT, is the go-to brand for heavy-duty equipment. Their mini-excavators like CAT 301.8 are the epitome of robustness. The 25 horsepower of this model is just right to tackle light and medium jobs. The compact design can be easily maneuvered, an extra benefit in urban construction sites.

Komatsu’s new engineering is the perfect balance for industrial ruggedness. The lightest of their mini diggers weighs 6500 lbs, while the heaviest weighs 19290 lbs. These machines are well known for their durability, besides their extraordinary adaptability. Whether it is necessary to put down or load up, it will be a job that a Komatsu will do in a record time.

When the questions are flexibility and convenience, then Bobcat has the answers. With features like a 50 hp engine and the sleek E50 design, Bobcat equipment has always been at the forefront of the equipment industry. The model has the engine with an output of 50 hp and it contains couplers that belong to the fast variety. This whole setups can be assembled and disassembled in an instant, so that apart from completing all the tasks, the company also increases its other operations’ performance tremendously.

A number of the Kubota models are limited to the 2160-12423-lbs weight span. They are built to accommodate all kinds of scenarios perfectly. However, a Kubota mini excavator can do anything from a simple reshaping of the garden to a complete construction project without any compromise of the machinery’s power, which is always an ideal option for every customer.

If you’re in the market for a mini excavator, first think about the work you’ll be doing with it. Each company will have its own unique model that will help to facilitate and execute the project while performing the same in a quick and efficient manner.

Since you’re in the decision-making phase about buying a mini excavator, the main point of concern is most likely whether to buy a new or a used one. Our article that follows will help you to make the right choice:

Brand new mini-excavators can be quite costly. Usually, their prices are set around from $40,000 to $150,000. Besides, the price of a new unit already includes the latest functions and technology. On the other side, you can find a used excavator at a price level down to from $20,000 to $75,000 in most cases. The major advantage of the lower initial cost helps save the budget. But there is a possibility of used machines to be broken and to need more repair. So, after all, don’t forget to take a closer look for some signs of wear and tear in the machine while purchasing a second hand.

Warranty and Maintenance Concerns

If you purchase a new mini excavator, it comes with a warranty. This will be very advantageous especially when something physical gets destroyed. New mini excavators usually have a 1-3 year warranty. The warranty covers the cost of repairs, thereby giving you the guarantee that you won’t be left out in the cold with a broken machine. On the other hand, if the ones you buy are used, it is uncertain that they have warranties; hence, you have to pay for the repair charges yourself. Also, take a look at the service history of the used equipment. A poor maintenance record could lead to expensive future repairs.

Depreciation and Resale Value

The value of a new mini excavator depreciates rapidly. The pullback becomes alarming in the first couple of years. However, a used one doesn’t lose its value as quickly as a new one due to the initial price drop of the new one therein. Nevertheless, in case of resale later, a used machine that has been well maintained may not experience a great loss in its value, therefore, leading to good prospects of being resold. Hence, the long-term value aspect is crucial in the event of asset acquisitions.

Case Studies of Long-term Ownership

For example, one contractor bought a new mini excavator at a cost of $100,000. After three years, the price of the machine had gone down to $60,000. At the same time, another contractor went for a second-hand one for $50,000 with its value decreased to $35,000 after three years. Clearly, the used equipment had retained a higher percentage of its original value. When the decision between the options of new and old is being deliberated, it is crucial to evaluate the monetary and non-monetary costs and benefits in the long run.

Taking into account the cost, warranty, and depreciation, you could then make a selection that is suitable for both your needs and your budget. Whether you set your eyes on a new mini excavator or a used one, always determine if it’s a perfect fit for the specific task you have in hand and the future plans you have.

Financing and Budgeting Tips for Mini Excavators

Mini excavators usually come with hefty price tags. However, here are a few ways to secure flexible and smooth financing for your new equipment.

Choosing a Financial Package

To start, approach banks and credit unions for loans. In construction, equipment, many such institutions have financing programs. Move on to the dealer and inquire about the financing. A good example is United Rentals with their very flexible financial conditions. Clear out anything you are uncertain about by asking questions like “what are the hidden fees associated with the loan?” and “Do you have a fixed rate of interest?”. Once you are aware of these fees, you can budget effectively. Moreover, you can consider third-party financers since it is possible that they have provided financed other businesses like yours.

Leasing Or Buying: Harsh Decisions To Make

Leasing is the most efficient way of managing your finances when financial flexibility is one of your main goals. The leasing option allows you not to make huge investments in the front and yet you are still able to work with the mini excavator. You can choose to pay a monthly fee and also, when the lease ends, you are able to upgrade to a new model. Such a thing is necessary if you require that particular equipment for a certain period. Purchasing is the right choice when the user calculates the use for a long period of time. Buying the machine makes you the owner now, which can be cost-effective in the long run. To make a choice, you need to take into account factors such as the frequency of use and the availability of cash.

Return on Investment Calculation Concerning Equipment

The importance of knowing your return on investment (ROI) cannot be ignored. Preliminary figures can demonstrate the possible time-saving feature of the equipment, e.g. the excavator. With this time-saving tool, you can accomplish onetime projects or you can start a new project. Compare this benefit with the machine’s cost. For instance, the excavator completing the projects faster by 15% directly translates to more contracts; thus, you have a good ROI. Study the return on investment every year to keep track of your financial progress.

Financial Points and Deductions

You may have an opportunity to benefit from tax deductions if you decide to buy a mini excavator. The IRS has been consistent with business equipment depreciation as a way forward to reducing income tax. In addition to this, buying energy-efficient models might come with benefits from the respective counties. It is wise to get advice from your tax consultant about these benefits. You will be more likely to enjoy the best of savings if you are in the company of a person with such understanding and knowledge.

By following these tips one can make it affordable to finance a mini excavator. Taking time to fit the needs and the budget for your project and come up with the right amount of money wisely by either leasing or buying the machine or taking advantage of tax benefits if any can be a good solution.

Operational Tips and Best Practices for Mini Excavators

Mastering the efficient skill of a mini excavator operator demands the know-how of both facets of operation and safety. Here are some tips to get on the right path of leading your operation effectively.

Basic Operation and Handling Skills

It is best that a trainee should first be familiarized with the different controls. Since there may be slight differences between the brands, one can refer to the manual. Training in an open area is a safe and sure way of handling the machine without too much pressure.

Going at a constant speed on turns ensures a safe and smooth transition of the load. For one, the steering wheel is delicate, so slight changes can make a huge difference.

Safety Protocols and Accident Prevention

Safety is the top priority of every operator of heavy-duty equipment. Before the engine is started, it is vital to ensure a thorough check of the machine. You have to check if there are bolts left undone and leave the job if there are any fluids leaking. Keep in mind that the area should no longer contain any debris or people.

In the process of digging, a loader is sure to remain stable if the loader is placed on a level surface. In case you need to slope the surface, you should do it very slowly and gradually. Another important thing is wearing your seat belt and helmet at all times.

Maintenance Best Practices

Machine life span is prolonged if regularly serviced. Compliance with the manufacturer’s guidelines on the periodic changing of the oil and filters is one of the most effective approaches. Additionally, it is a good idea to grease the pivot points daily to prevent them from rusting and to keep them running smoothly.

It’s equally important to check if the tracks and tires are in good condition, as they serve to convey the vehicle and its load. In case of any signs of wear, it would be appropriate to replace them at the earliest to avoid any accidents at the work site. Inspections done according to the plan will eliminate the need for expensive repairs tirelessly.

Enhancing Productivity and Efficiency

Desire to raise productivity? Get familiar with your work. Use attachments that are appropriate for the type of work you will be doing. Take as an example a trenching bucket that is more suitable for deep digging than a standard bucket.

The replacement of the attachments in a very short time is time-saving. Fill the idle time to a minimum using fuel wisely. It not only saves your money but is also environmentally friendly.

Imparting the above practices to your mini excavator operation will make it safer and more efficient. With your own safety well taken care of, you will also see a big improvement in the quality and speed of your exc

Future Trends and Innovations in Mini Excavators

Wide-legged mini-excavators are becoming the talk of the market! Let’s figure out what the novelty is all about!

Automation and Smart Technology Integration

Automation has really caught the attention of many industries. Just imagine that your mini excavator can be in control and can do most of the work without much manual labor. The systems that are GPS-guided which companies use now are also being utilized for this purpose of doing the work with ease and more accuracy. They are really great, aren’t they? The amount of time it takes to get the work done is reduced and efficiency is increased. So, you are saving more time for Job B without taking 9 times out of 10 for Job A!

Automation and Smart Technology Integration

Automation has really caught the attention of many industries. Just imagine that your mini excavator can be in control and can do most of the work without much manual labor. The systems that are GPS-guided, which companies use now, are also being utilized for this purpose of doing the work with ease

Eco-friendly and Sustainable Models

It is not a new thing, but a necessity, that people are preferring electric and less harmful sources of energy.

The Role of AI in Construction Equipment

Artificial intelligence (AI) is used not just in robots and apps. AI has found its place also among mini excavators. AI itself can do the job of predicting maintenance requirements; thus, faults are eliminated. Additionally, AI can be trained to learn from past experiences and the prevailing surroundings and hence adjust the operations accordingly, thereby easing the operations. To put it differently, a mini assistant will be there inside the excavator to instruct you on the difficult tasks.

Predicted Market Changes by 2030

Will mini excavators remain the same for the next decade at least? According to Market Research Future, the market will increase by 4.8% annually by 2030. The majority of new clients will be small-sized businesses and DIY enthusiasts. Very soon, people will be attracted to these new versions of mini excavators that are very portable with futuristic tech features. But certainly, these will be ideas and companies that ensure they are well represented and in compliance with green initiatives that will shape the future of the industry.

It is planned for mini excavators to become energy efficient and environmentally friendly. Contracted labor, as well as DIY handymen, can cut their own costs, save time, and even more, use environmentally friendly technologies if they are smart enough to embrace these new technologies. Such actions are forward-looking and promising to us all! 🚀

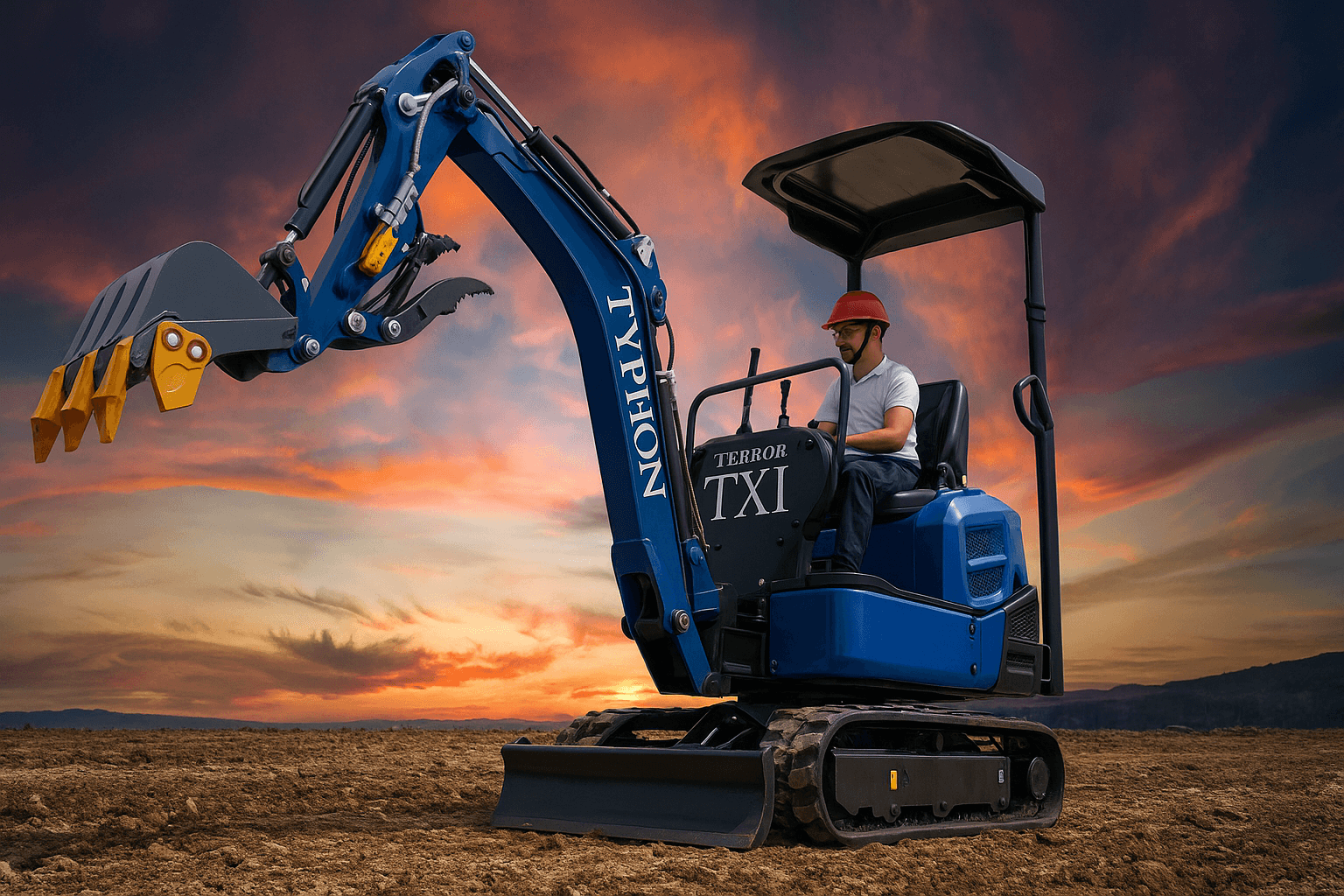

Let’s get to the point! 🎯 We have now known the mini excavators‘ nature, which is that they are multitasking, and small machines that are good for everything from urban areas to large gardens. Furthermore, you have seen examples of their most desired characteristics, the choice between which model to go for (Caterpillar or Typhon), and the financial strength of the firm. Furthermore, we’ve demonstrated the common operational challenges and the strategic methods for ensuring safety and productivity.

Furthermore, the issue of getting a mini-excavator right has been a critical matter that calls for a clear understanding of the need and the budget at hand as the first step. The next thing for you will be to venture into the market and give some models a test run. A trial run will help you ascertain whether this is what you need! This period is the ideal time to exploit a machine’s increasing popularity and innovative features as an investor in the construction industry. Therefore, one can finally be capable enough to perform his industrious task with ease and confidence. Are you set to unravel your projects to the last layer with confidence? 🚜

Frequently Asked Questions

What is a mini excavator, to be more exact?

A mini excavator is a shrunken and a multi-functional machine that is used for digging and earthmoving. Such an equipment is usually made for operation in the places where it is simply impossible for the regular machinery to work efficiently. Shorter work tasks like trenching, digging a foundation, or dismantling depend on these devices in the construction and landscaping domains because of their size and yet powerful functionalities.

How are mini excavators different from standard excavators?

Mini excavators are the downsized versions of standard excavators, being about three to six meters long and weighing less than seven tons. The tasks assigned to the former are not so extensive, hence mini devices are employed for small and precise work in fleet settings. However, size does not taint the power and flexibility of mini excavators.

What are the most reputable mini excavator brands?

The best brands in the mini excavator business are Caterpillar, Komatsu, Bobcat, and Kubota. These companies are recognized for their uptime and offering a variety of models that address different tasks and meet the needs of various budgets, from robust construction work to well-detailed landscaping work.

Is it wise to purchase a new or a used mini excavator?

To buy new or used mini excavators is a hotly debated issue, which can only be solved by considering your financial status and objectives. Brand new equipment has the most modern features and usually comes with warranties, but they are highly priced. On the other hand, second-hand ones are not only cost-effective at the start but also lead to more wear and tear. Estimating the costs with potential wearing out and repair shall help you to make a choice.

How can I fund my mini excavator purchase?

A variety of financing choices for mini excavators is now available. These options include bank loans, seller financing, and leasing. Each type carries its own benefits, like low initial costs in leasing or the prospect of ownership with a loan. The key to taking the right choice is to estimate your project’s period and your financial strength.

What are the essential maintenance practices for mini excavators?

Maintenance at regular intervals is very important in the extension of the mini excavator lifespan. This includes greasing pivot points with oil daily, frequent oil changing, and routine inspections to check if the tracks or tires are worn. Adherence to the manufacturer’s instructions would minimize expensive repairs and downtimes.

What technological breakthroughs in mini excavators can we anticipate?

Absolutely, the latest developments include automation and intelligent technology, which enhance eco-friendliness and incorporate AI systems for predictive maintenance. Such innovations are designed to optimize the productivity of mini excavators, reduce the carbon footprint, and increase the precision of operations, thereby, driving the evolution of the sector.