The Ultimate Guide to the Skid Steer Loader

If you spend any time on a construction site, a farm, or a large landscaping project, you will inevitably see a compact machine darting back and forth with frantic energy. It spins within its footprint, lifts heavy loads high into the air, and changes tools faster than a pit crew changes tires.

This is the skid steer loader.

While it may look like a simple bucket on wheels, the skid steer is widely considered the most versatile piece of heavy equipment ever invented. It serves as the foundation for small-to-medium-sized construction projects and is often overlooked in agricultural work.

In this detailed guide, we will explore everything you need to know about the skid steer: its fascinating history, the mechanics behind its movement, the debate between wheels and tracks, and the vast ecosystem of attachments that make it indispensable.

A skid steer loader is a small, rigid-frame, engine-powered machine with lift arms that can attach to a wide variety of labor-saving tools or attachments. It is one of the most versatile and recognizable pieces of heavy equipment in construction, landscaping, and agriculture.

Here is a breakdown of what makes it unique:

1. Why is it called a Skid Steer?

The name comes from the unique way the machine turns.

- No Steering Wheel: Unlike a car, the wheels do not turn left or right. They are fixed in a straight line.

- Skidding Motion: To steer, the operator increases the speed of the wheels on one side while slowing down or stopping the wheels on the other side. This defect causes the machine to drag (or skid) its fixed wheels across the ground to rotate.

- Zero-Turn Radius: This advantage allows the machine to spin 360 degrees within its own footprint, making it incredibly agile in tight spaces like narrow alleys or inside barns.

2. The Mechanics: Why Does it Skid?

The defining feature of this machine is right there in the name: Skid Steer.

In a standard car or truck, the front wheels turn left or right to guide the vehicle. A skid steer is different. The wheels (or tracks) are fixed in a straight line. There is no steering wheel mechanism connected to the axles.

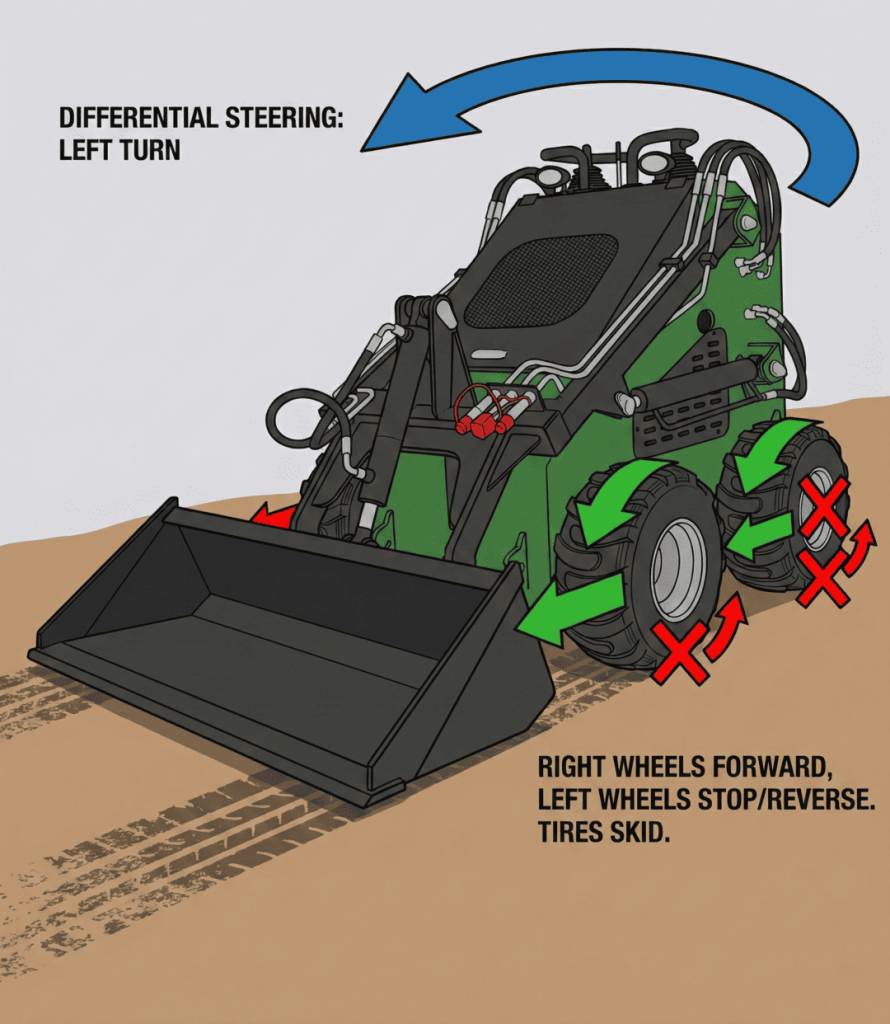

Differential Steering

To turn the machine, the operator engages the left-side drive and the right-side drive at different speeds.

- To turn left: You push the right wheels forward and stop (or reverse) the left wheels.

- The Result: The machine pivots. Because the wheels are fixed, the tires literally drag—or skid—across the ground to change the vehicle’s orientation.

This “counter-rotation” capability allows for a zero turning radius. A skid steer can pivot 360 degrees while standing in one spot. This makes it the only machine capable of working in narrow alleyways, inside barns, or between tightly packed houses where a standard tractor would get stuck.

3. Radial Lift vs. Vertical Lift: The Great Debate

When buying or renting a skid steer, one of the first technical choices you face is the “lift path.” The loader arms are engineered to move the bucket in one of two ways. Understanding this is crucial for efficiency.

A. Radial Lift

This is the original design. As the arms lift the bucket, they swing out in an arc (like your arm moving from your hip to your shoulder).

- The Path: The bucket starts close, swings out further at the midpoint of the lift, and pulls back closer to the machine at full height.

- Best For: Digging and grading. Because the bucket is furthest away from the machine at the mid-range (eye level), it offers the best reach for dumping over low walls or backfilling trenches.

- The Downside: At full height, the bucket pulls back toward the cab, making it harder to load high-sided dump trucks.

B. Vertical Lift

This design uses a complex linkage system (often resembling a hinge) to keep the bucket moving in a nearly straight line up and down.

- The Path: The bucket extends further away from the machine the higher it goes.

- Best For: Loading trucks and pallets. Because the bucket stays far out at maximum height, you can reach the center of a dump truck or stack heavy pallets without bumping the tires against the truck.

- The Downside: Generally more expensive and involves more moving parts (pivot points) to maintain.

4. Wheels vs. Tracks: The Rise of the CTL

For decades, the skid steer was purely a wheeled machine. However, recently, the Compact Track Loader (CTL) has surged in popularity. A CTL is essentially a skid steer upper body mounted on rubber tracks similar to a tank.

Which one is better? It depends entirely on the ground beneath your feet.

The Wheeled Skid Steer

- The Surface: Best for rough, abrasive surfaces like asphalt, concrete, and rocky ground.

- Speed: Generally faster across the job site.

- Cost: Tires are cheaper to replace than tracks, and the machine itself is usually less expensive to buy.

- Maintenance: Lower maintenance expenses (fewer moving undercarriage parts).

- Weakness: They struggle in mud. The thin tires sink, and the machine can easily get bogged down.

The Compact Track Loader (CTL)

- The Surface: Best for mud, sand, snow, and sensitive turf (lawns).

- Flotation: The tracks distribute the machine’s weight over a huge surface area. A 4-ton machine on tracks exerts less ground pressure per square inch than a human footprint. It floats over mud.

- Stability: A much smoother ride for the operator.

- Weakness: Tracks are incredibly expensive. If you run a CTL on concrete or asphalt, you will chew through thousands of dollars of rubber in no time.

5. The Heart of the Beast: Hydraulics and Attachments

If you take nothing else away from this guide, remember this: A skid steer is not a bucket loader; it is a hydraulic power plant.

The bucket is just the default tool. The real magic lies in the auxiliary hydraulic system. Two couplers on the arm allow you to plug in powered tools, transforming the machine into almost anything you need.

The “Swiss Army Knife” Capabilities:

- Auger: Turns the machine into a drill rig for fencing or tree planting.

- Trencher: Digs precise, narrow lines for irrigation or electrical conduit much faster than an excavator.

- Cold Planer: A machine that removes the upper layer of the asphalt by a rotating drum.

- Brush Cutter/Mulcher: A device which is capable of cutting of tall grass and even small trees, thus it can be used for fast land cleaning.

- Grapple Bucket: A pair of two hydraulic “jaws” which are used for holding down rubbish, logs, or demolition waste tightly.

- Snow Blower: It is used for the removal of large amounts of snow from driveways and parking lots.

Standard Flow vs. High Flow

When selecting a machine for attachments, you must know the flow rate.

- Standard Flow: Sufficient for buckets, grapples, and simple augers.

- High Flow: A specialized hydraulic package that pumps more gallons per minute (GPM) at higher pressures. You must have high flow to run heavy-duty attachments like asphalt planers or forestry mulchers effectively.

The Heavy Hitters: A Deep Dive into Skid Steer Attachments

A skid steer without attachments is just a bucket on wheels. While the bucket is useful, the true genius of the machine is its ability to transform into a specialized rig for almost any industry. The hydraulic system on a skid steer is like a single power source that can be used for any tool. It enables the use of tools that need a separate, costly machine for a short period.

Without any attachments, your skid steer is basically a glorified bucket. But these six attachments can take your little machine and turn it into a construction powerhouse.

1. The Auger

The Precision Driller

The auger attachment transforms your skid steer into a mobile drilling rig. It consists of a hydraulic motor that hangs from the loader arms, connected to a long, corkscrew-shaped drilling bit.

How It Works

When the hydraulics are engaged, the motor spins the bit with immense torque.

The operator applies downward pressure with the loader arms, thus forcing the screw to go into the ground. The auger is spinning, hence the “flighting” (the spiral blades) is taking the loose soil up and out of the hole, leaving a clean, cylindrical void.

Best Applications

- Fencing: Simply put, this is the auger’s bread and butter. In a matter of hours, it can drill hundreds of post holes, a job which would take a crew of men weeks if done manually.

- Tree Planting: Landscapers go for large-diameter bits (24” to 36”) to make the perfect planting holes for root balls, thus ensuring the soil is loose and aerated for the new tree.

- Deck Footings: Very important for drilling deep holes for concrete piers when building decks or pole barns.

Pro Operator Tip

Watch the Swing: When moving with the auger, the heavy bit acts like a pendulum. If you stop or turn too fast, the bit can swing wildly and damage property or the machine. Always keep the bit low to the ground during transport and stabilize it before drilling.

2. The Trencher

The Utility Surgeon

An excavator excavates a large, messy hole, while a trencher creates a surgical line. It looks like a giant chainsaw attached to the front of the machine.

How It Works

The trencher uses a heavy-duty chain equipped with cutting “teeth” (often tipped with tungsten carbide). As the chain rotates, the operator drives the skid steer in reverse. The chain tears into the ground, tearing the earth out of the trench and, through a spoil auger, depositing it back on the side in a heap.

Best Uses

- Irrigation Systems: Great for the installation of long lines of sprinkler pipe in parks or on golf courses with very little harm to the grass that is left around.

- Electrical & Fiber Optic: Makes narrow trenches (generally 6” to 12” in width) for the burial of conduit or laying of cables underground.

- Drainage: The most suitable method for the installation of French drains intended for the control of water runoff.

Pro Operator Tip

Tension Matters: Just like a chainsaw, the chain on a trencher can get loose. If it’s too loose, it can derail. If it’s too tight, it wears out the bearings. Check the tension every few hours of operation, especially when digging in rocky soil.

3. The Cold Planer

The Road Warrior

The cold planer is a heavy-duty attachment designed for roadwork and pavement maintenance. It is one of the more expensive and complex attachments, usually requiring a “high flow” hydraulic system to operate efficiently.

How It Works

Inside the housing is a heavy steel drum covered in carbide-tipped picks. The drum spins at high speeds to grind away asphalt or concrete surfaces. Truly, it doesn’t wreck the street; it takes off the specified amount of the surface by grinding, and the road that is left is rough and textured so that it can bond perfectly with the new asphalt.

Best Applications

- Pothole Repair: The planer by means of milling a square “keyway” around the broken area, thus allowing for a permanent patch, does it better than just filling a pothole (which most of the time fails).

- Removing Striping: The removal of road markings such as old lane markers or thermoplastic striping can be done by shaving them off without hurting the road underneath.

- Transition Milling: By smoothing out the “bump” that is the junction of the new driveway and the old road by the planer, the next can be done without the road structure showing.

Pro Operator Tip

Water is Key: Milling generates immense heat and friction, which kills the carbide teeth. Most planers come with a water kit (a tank and spray nozzles). Always run the water system to cool the bits and suppress the hazardous silica dust.

4. The Brush Cutter/Mulcher

The Land Clearing Beast

When you are facing a field of 6-foot-tall weeds, thick brambles, or saplings, a standard lawnmower is useless. You need a brush cutter (rotary mower) or a mulcher (drum style).

How It Works

- Brush Cutter (Rotary): Imagine a lawnmower on steroids. Heavy steel blades spin horizontally beneath a deck. They use momentum to slash through thick grass and saplings up to 3–4 inches thick.

- Mulcher (Drum): A horizontal drum with fixed teeth spins vertically. It grinds trees and brush into fine wood chips (mulch) instantly.

Best Applications

- Right-of-Way Maintenance: Removing trees and brush from under power lines or along highways.

- Fire Breaks: Quickly removing vegetation to create a fire break to prevent wildfires from spreading.

- Site Prep: Converting an overgrown land into a site ready for building in just a few hours.

Pro Operator Tip

Keep the RPMs Up: These attachments are power-hungry. If you drive too fast into thick brush, the drum slows down, and you lose cutting power. Listen to the engine; if it starts to bog down, slow your travel speed to let the cutter head recover its momentum.

5. The Grapple Bucket

The Iron Claw

The grapple bucket is the most popular upgrade from a standard bucket. It features two independent hydraulic cylinders that operate a set of curved “jaws” or clamps over the top of the bucket.

How It Works

Unlike a standard bucket where you have to balance the load, the grapple physically clamps down on the material. This allows you to grab uneven, bulky, or loose objects that would otherwise fall out.

Best Applications

- Disaster Cleanup: Unmatched for moving storm debris, fallen tree branches, and mixed trash after a hurricane or tornado.

- Demolition: It can tear down a drywall partition and grab the entire pile of studs and sheetrock in one bite to load into a dumpster.

- Log Handling: The jaws allow you to pick up logs lengthwise or grab a bundle of brush securely.

Pro Operator Tip

Don’t Twist: The hydraulic cylinders on the grapple are strong but vulnerable to twisting forces. When you have a heavy load clamped in the jaws, avoid dragging the bucket sideways across the ground, as this can bend the grapple teeth or cylinders.

6. The Snowblower

The Winter Savior

For contractors in northern climates, the snowblower attachment turns the off-season into a profitable season. It is far more efficient than plowing when snow piles get too high.

How It Works

A large auger at the front skims the snow and feeds it into a high-speed impeller fan. The fan shoots the snow out of a directional chute, launching it 30 to 40 feet away.

Best Applications

- Deep Drifts: Plows can only push snow so far before the pile becomes immovable. A blower takes off the snow fully, hurling it over fences or into trucks.

- Narrow Spaces: Perfect for walking path and driveway cleaning in small areas where it is not possible to pile the snow on the sides.

- Loading Trucks: The pipe can be directed to load dump trucks that are used for street cleaning after removing the snow.

Pro Operator Tip

Flow Management: Wet, heavy snow requires more power than light powder. If the chute clogs, it’s usually because you are driving too fast. Slow down to let the impeller clear the snow before feeding it more. Never use your hand to unclog the chute while the machine is running.

The Ultimate Attachment Arsenal: Transforming Your Skid Steer

A skid steer loader is only as good as the tool attached to it. While the machine provides the muscle, these attachments provide the talent. Whether you are running a specific model like the TYPHON STOMP or a standard universal machine, this lineup covers every possible application from heavy demolition to delicate lawn care.

Here is a detailed breakdown of the essential attachments that turn your loader into a one-machine fleet.

1. Land Clearing & Forestry

Skid Steer Loader Mulcher

The Forest Eraser This machine is the heavy artillery of land clearing. The Mulcher doesn’t just cut down trees; it eliminates them. Designed for forestry professionals, this attachment uses a high-speed rotating drum equipped with carbide teeth to shred underbrush, wild overgrowth, and trees up to several inches thick.

- Why You Need It: It eliminates the need to haul debris away. By grinding vegetation into a fine mulch, you return nutrients to the soil and clear land in a single pass.

- Best For: Creating fire lanes, clearing right-of-ways, and reclaiming overgrown property.

Skid Steer Loader Stump Grinder Attachment

The Finishing Move Cutting a tree down is the easy part; dealing with the stump is the headache. This attachment mounts a cutting wheel with carbide teeth that grinds stumps down well below ground level. It allows you to sweep the tool side-to-side, chewing through hardwood and roots until the stump is reduced to woodchips.

- The Advantage: Much faster and less destructive to the surrounding lawn than digging the stump out with a bucket.

Skid Steer Loader Brush Cutter/Lawn Mower Attachment

The High-Speed Groomer While the mulcher handles trees, the mower attachment is designed for tall grass and thick weeds. It floats over the terrain, maintaining a consistent cut height even on uneven ground.

- Application: Perfect for roadside maintenance, clearing vacant lots, or mowing large pastures where a standard tractor might be too tippy.

2. Excavation & Digging

NEW Backhoe Digger (For TYPHON STOMP)

The Mini-Excavator Converter This attachment is a game-changer for owners of compact loaders like the TYPHON STOMP. It effectively turns your skid steer into a mini-excavator. It features a digging arm and bucket that allows you to dig deep trenches or footings from a stationary position.

- Human Touch: It saves you the cost of hauling a second machine to the job site. You get the digging depth of an excavator with the mobility of a skid steer.

TYPHON Skid Steer Loader Trencher Attachment

The Surgical Line Cutter When you need to lay pipe or electrical cable, you don’t want a massive trench—you want a clean slot. The Trencher uses a heavy-duty chain with cutting teeth to slice through the earth.

- Pro Tip: This specific TYPHON model is engineered to handle rocky soil without stalling, ensuring a consistent depth for irrigation or utility lines.

Skid Steer Loader Earth Auger Attachment

The Hole Specialist Stop digging post holes by hand. The Earth Auger is a hydraulic drill that bores perfect, vertical holes in seconds. Whether you are installing a fence, planting trees, or pouring concrete piers, this tool ensures every hole is uniform.

- Versatility: You can swap bits ranging from small 6-inch pilots to massive 36-inch tree planters.

3. Earthmoving & Grading

Skid Steer Loader Land Leveler Attachment (USA)

The Driveway Doctor Also known as a planing beam or grader, this tool is essential for road maintenance. It cuts down high spots and fills in low spots simultaneously as you drive.

- Why It Works: Unlike a bucket, which follows the bumps, the long frame of the leveler bridges gaps, creating a perfectly flat surface for gravel driveways or seedbeds.

Skid Steer Loader Bull Dozer Attachment

The Pusher Sometimes you just need raw pushing power. This 6-way adjustable blade turns your skid steer into a mini-dozer. You can angle the blade to windrow material to the side or tilt it to cut drainage ditches.

- Best For: Backfilling trenches, spreading piles of fill dirt, and rough grading.

Skid Steer Loader 4-in-1 Bucket Attachment

The “Clamshell” Wonder If you can only buy one bucket, make it this one. It functions as:

- A Bucket: For loading and carrying.

- A Dozer: Open the jaws to push dirt.

- A Grader: Open the jaws and drag backward to smooth dirt.

- A Grapple: Clamp down to pick up logs or rocks.

Skid Steer Loader Rock Bucket Attachment (USA)

The Sifter This bucket features long, skeleton-like tines instead of a solid bottom. When you scoop a pile of dirt, the loose soil falls through the gaps, leaving only the rocks and debris in the bucket.

- Use Case: Essential for farmers clearing fields of stones before planting, or for construction crews cleaning up job site debris.

4. Demolition & Hardscape

Skid Steer Loader Hydraulic Hammer/Concrete Breaker (USA)

The Jackhammer on Steroids Demolition work is brutal, but this attachment makes it easy. It delivers high-impact blows to shatter reinforced concrete, asphalt, or rock.

- The Feel: You will feel the power of this tool in the cab. It’s designed for breaking up driveways, sidewalks, and foundations quickly so they can be hauled away.

Skid Steer Loader Grappler (Grapple Grabber)

The Iron Hand This is the ultimate cleanup tool. With two independent hydraulic claws, it bites down on uneven loads.

- Best For: Moving brush piles, demolition scrap, logs, and large rocks that would tumble out of a standard bucket. It secures the load so you can move fast without spilling.

Skid Steer Loader Ripper Attachment

The Ground Breaker When the ground is frozen, packed hard, or full of roots, a bucket just skims the surface. The Ripper uses heavy steel shanks to slice deep into the ground, “ripping” the soil structure to loosen it up for digging or grading.

5. Maintenance & Specialty Tools

TYPHON Skid Steer Loader Snow Blower Attachment

The Winter Warrior Don’t just push the snow into a pile that blocks your view; remove it. This blower intakes snow and launches it up to 40 feet away.

- Why TYPHON? It is a great tool to be used in a situation where a lot of snow is to be removed, and to be able to do so with a minimum of clogging, it is also suitable for cutting down long driveways and parking areas even if the snow is wet and heavy.

Skid Steer Loader Sweeper Attachment (USA)

The Job Site Janitor Bristles on the rotating brush of this attachment are refreshed from a collection hopper. It cleans dust, mud, and debris from the pavement and gathers it for unloading.

- Application: Vital for keeping public roads clean when trucks are leaving a muddy construction site or for cleaning parking lots and warehouses.

Skid Steer Loader Rotary Plow Tiller Attachment

The Soil Prep Pro

Farmers and landscapers cannot do without this tool. It goes deep into the soil, mixing in compost or fertilizer and smashing chunks of soil to get a soft, well-ventilated seedbed that is suitable for planting.

Skid Steer Loader Lawn Scarifier

Lawns accumulate thatch—a layer of dead grass that suffocates the soil. That is why they need the scarifier, which works very gently by raking the surface, thus removing moss and thatch without damaging the healthy grass, with water and air being able to reach the roots now.

Skid Steer Loader Trench Filler

The One-Pass Closer Digging the trench is only half the job. This specialized tool features augers or blades that guide the spoil pile back into the trench as you drive alongside it. It is significantly faster and neater than trying to push the dirt back in with a bucket.

Skid Steer Loader Fork Pallet Attachment

The Logistics lifter Simple but indispensable. This turns your skid steer into an all-terrain forklift.

- Necessity: You cannot unload a delivery truck of sod, brick, or cement bags without it. Unlike a warehouse forklift, a skid steer with forks can carry pallets across mud and rough terrain to exactly where they are needed.

6. The Operator Experience: Cab and Controls

Entering a skid steer is a unique experience. Because the lift arms run along the sides of the vehicle, there are no side doors. You must climb over the bucket (using non-slip steps) and enter through the front windshield area.

Once inside, it can feel claustrophobic to the uninitiated, but modern cabs are marvels of engineering. They are often pressurized to keep dust out, air-conditioned, and equipped with Bluetooth radios.

Control Patterns

Historically, skid steers used hand and foot controls (hands for steering, feet for lifting the bucket). This required significant coordination.

Nowadays, ISO joystick controls are what is commonly used.

- Left Joystick: Directs the vehicle through the various maneuvers of moving forward, reversing, turning left, and turning right.

- Right Joystick: Manipulates the loader arm (boom up, boom down, bucket curl, bucket dump).

With this clever design, operators can still perform at a high level for long hours while the old manual lever method used more of their energy and caused faster fatigue.

7. Safety: The Bucking Bronco

Despite their utility, skid steers can be dangerous. Their short wheelbase (the distance between front and rear wheels) makes them prone to a “teeter-totter” effect.

If an operator lifts a heavy load too quickly while moving forward, the machine can tip forward onto its front tires. Conversely, reversing abruptly can cause the machine to “buck” backward. This bouncing ride is why seasoned operators always wear their seatbelts (and the lap bar restraint is mandatory for the machine to start).

Visibility is another major challenge. The large lift arms and the engine sitting directly behind the driver create significant blind spots. Rear-view cameras and side sensors are becoming standard safety equipment on modern job sites to prevent backing into walls—or worse, people.

8. Buying vs. Renting: A Quick Guide

When to Rent:

- You are a homeowner doing a weekend project (grading a driveway, moving mulch).

- You need a specific attachment (like a breaker) for a one-off job.

- You don’t have a heavy-duty trailer and truck to tow the machine (rental companies deliver).

When to Buy:

- You are a contractor using the machine more than 3 days a week.

- You need the machine available 24/7 for snow removal contracts.

- You have the mechanical aptitude to handle grease, oil changes, and track tensioning.

Conclusion: The King of the Compacts

The skid steer loader has come a long way from the turkey barns of Minnesota. It has evolved into a sophisticated, computerized, comfortable, and incredibly powerful machine.

For the construction industry, it represents the ultimate efficiency—one operator, in one machine, performing the work of ten laborers. Whether on wheels or tracks, radial or vertical, the skid steer remains the undisputed king of compact equipment. It is the one machine that no serious contractor can afford to be without.