Walk-Behind vs Ride-On Roller Compactors

Choosing the right machinery is key to the success of any road construction or soil compaction project. The issue of walk-behind vs. ride-on roller compactors is something that every site manager and contractor will have to deal with sooner or later.

The decision is not only about the size of the machines; it also concerns the efficiency, budget, site constraints, and the specific density of the material you are working with. Whether you are paving a giant highway or compacting a very narrow trench for utilities, knowing the differences between these two types of rollers will be of enormous help.

At Roller Compactor, we are here for you to make the right choices, and that is why this guide will give you all the details on machine specifications as well as their pros and cons to help you choose the one that fits your needs.

Why Compaction Equipment Selection is a Major Decision

Once we start to elaborate on the differences, we first need to realize why the decision is a significant one. Compaction involves increasing the particle density of soil or asphalt by pushing out the air trapped between soil particles/aggregate particles.

Picking a machine that doesn’t have enough weight will result in your structure failing, potholes developing, and foundations sinking. While a massive ride-on roller being used to compact soils in a small delicate site can damage the adjacent structures and is unnecessary.

- Structural Integrity: Good compaction makes the material strong enough to handle the load placed on it without settling.

- Cost Effectiveness: Picking the appropriate machine can help you avoid over compaction (wasting time/fuel) and under-compaction (price of rework).

- Safety Compliance: Highly secure job sites may restrict the type of equipment to be used for safety purposes.

Deep Dive: Walk-Behind Roller Compactors

Walk-behind rollers, aka pedestrian rollers, play a vital role in the precise compaction of soil. They efficiently deliver the required compaction of soil to fine detail at the job site situated in areas or spots that are relatively smaller and more difficult to reach than the ride-on roller.

The operator controls them using a handle or a remote control while walking behind the machine. In the walk-behind vs. ride-on roller compactors showdown, these units hold their own in tight spaces.

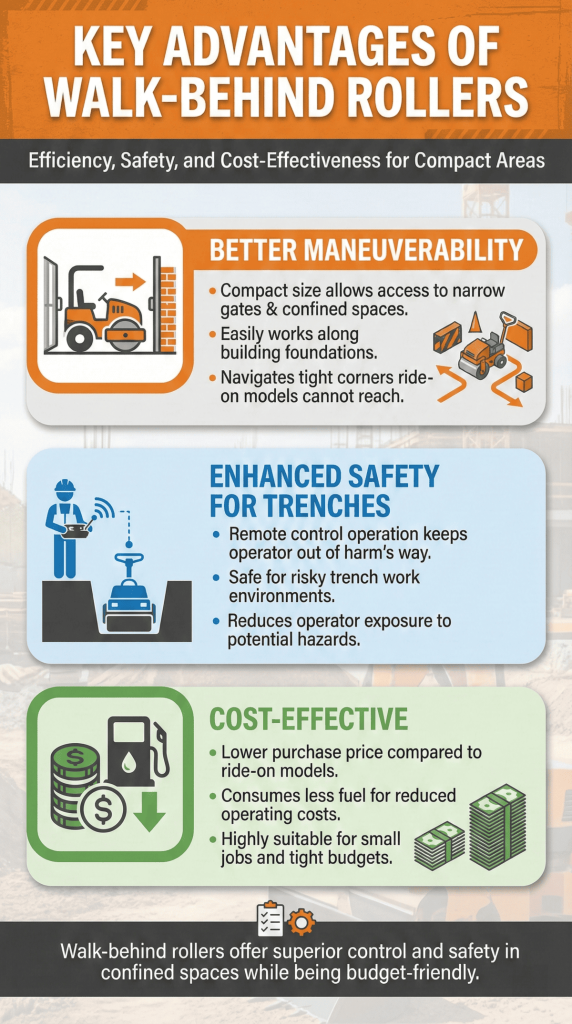

Key Advantages of the Walk-Behind Rollers:

- Better maneuverability: The compact size of these machines allows them to fit through narrow gates, work along building foundations, and make tight corners that a ride-on roller could not access.

- Enhanced Safety for Trenches: The operator can remotely control the equipment and thus stay out of harm’s way if the area inside the trench is risky.

- Enhanced Safety for Trenches: They are cheaper to buy, consume less fuel, and thus have lower operating costs, making them highly suitable for small jobs where the budget is a concern.

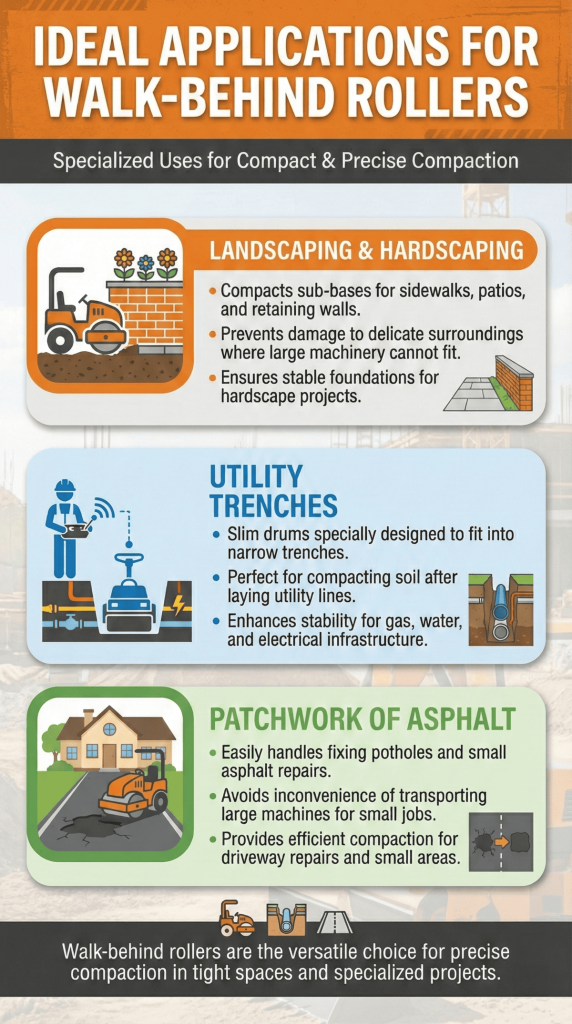

Walk-Behind Rollers are ideal for:

- Landscaping and hardscaping: Sidewalks, patios, and retaining walls are all examples of where sub-bases need to be compacted but large machinery is not an option due to their potential to damage the surroundings.

- Utility trench: Their slim drums are specially made to fit into the trenches used for laying gas, water, and electrical lines.

- Patchwork of Asphalt: Whenever it comes to fixing potholes or small areas of a driveway, a walk-behind roller can easily handle these tasks without the inconvenience of moving a big machine.

Deep Dive: Ride-On Roller Compactors

On the other hand, ride-on roller compactors are at the other end of the spectrum. They are like the beasts of the construction world and are necessary for large-scale infrastructure projects. The name itself tells you that the operator can sit in a cab or on a seat on top of the machine. When you compare walk-behind vs. ride-on roller compactors, ride-on models take the trophy for speed and power.

Main Benefits of Ride-on Rollers

Strongly Perform High Compaction: A roller compactor is a type of heavy machinery that is used for compacting soil or different surfaces to make them hard and smooth. The ride-on roller compactors come with a high static and vibratory forces that allow them to compact the road base with thicker lifts (layers) and in fewer passes, which is a critical factor in the case of highways having density specs that are very strict.

Keep the Operator Comfort and Less Fatigue: If the operator work for day-long, then the ergonomic seating (sometimes with the climate control in the enclosed cabs) is a huge help in reducing operator fatigue (to greatly) compared to walking behind a vibrating machine for hours.

When Working on Big Areas, Be More Efficient: Because of their drum which is wider and their travel speed which is faster, a ride-on roller can cover the widest area possible in the least time. They even say that a project can be done within two days if a foot machine is used. Therefore, using ride-on rollers may be considered as one of the key factors to projects being on schedule.

Ideal Applications for Ride-On Rollers:

Highway and Road Construction: This is the typical case where ride-on rollers are used for thousands of miles of laying asphalt or for compacting the road base, where the elements speed and consistency are very important.

Large Parking Lots: Parking lots for commercial and industrial purposes require a flat surface to be laid which can endure the heavy truck traffic. This can be achieved by using the heavy static weight of ride-on rollers.

Airport Runways: Projects such as airport runways are so huge that they require hard compaction to be done throughout the entire surface with only heavy-duty ride-on rollers being able to achieve such compaction densities consistently.

Comparison of Two Roller Compactors: Walk-Behind vs Ride-On Roller Compactors

Making the right purchase or rental decision takes into consideration certain factors, which we will discuss. It is hardly ever so that one is better than the other, but which is “better for you” at the present moment.

1. Project size and site challenges

In a nutshell, the size of your site will largely determine the type of machine you use. Imagine the scenario of a residential backyard with a gate size of 40 inches; clearly, a ride-on roller is out of the question.

However, in the case of a 10-mile road, a walk-behind roller would take weeks to complete what a ride-on could accomplish within days.

- Narrowest access point: If you have less than 48 inches, then your choice of machine is limited to the walk-behind roller.

- Area coverage: Generally, walk-behind rollers are good for small spaces up to 2,000 square feet, whilst ride-on rollers gain efficiency as the size increases beyond 5,000 square feet.

- Surface conditions: A steep slope would be risky for a ride-on roller because of its high center of gravity; to be safe, remote-controlled walk-behind rollers might be used there.

2. Budget and ROI

Your budget impacts the walk-behind vs. ride-on roller compactors conversation tremendously. So different are not only the acquisition costs but also the operational costs vary greatly)

- Purchase or Leasing Cost: The price difference between the ride-on and walk-behind roller can vary 3 to 10 times. Should it be a unique small project, a ride-on rental may wipe out your profits.

- Transportation: Large Ride-on rollers usually require a specialized heavy-haul lowboy trailer and a licensed driver, thus significantly adding transport costs. Walk-behind rollers can be transported on a normal trailer or the bed of a pickup truck.

- Fuel Cost: Larger engines in the ride-on rollers run on much more fuel (diesel), so please factor in fuel costs before bidding on the project.

3. Compaction performance and efficiency

Finally, the objective is always to realize a particular level of soil density.

The depth at which soil can be effectively compacted: A ride-on roller can easily manage soil layers (lifts) of 12 inches or more depending on its weight. On the other hand, walk-behind rollers are mostly limited to thinner layers of 4-8 inches.

- Passes needed: A ride-on roller may be able to achieve target density in considerably fewer passes than a walk-behind roller. A walk-behind roller, on the other hand, may have to double or even triple the number of passes to get the job done.

- Surface finishing: For the surface finishing of asphalt, tandem ride-on rollers generally produce an even smoother more consistent finish (mat) than walk-behind rollers, which sometimes can leave marks if the operator is not very experienced.

Comparison Table: At a Glance

| Feature | Walk-Behind Roller | Ride-On Roller |

| Operator Position | Walking behind or Remote Control | Seated on machine/cabin |

| Machine Weight | Typically 1,000 lbs – 3,500 lbs | 2 tons to 20+ tons |

| Drum Width | 20 inches – 35 inches | 35 inches – 84+ inches |

| Compaction Force | Low to Medium | High to Very High |

| Transport | Pickup truck or small trailer | Heavy-duty trailer / Lowboy |

| Best Use Case | Trenches, patchworks, tight spaces | Highways, parking lots, large bases |

Walk-Behind vs Ride-On Roller Compactors: FAQs

Do walk-behind rollers compact asphalt well?

Walk-behind asphalt rollers made particularly for this task are very efficient. Dual smooth drums plus water sprinklers to make sure hot asphalt doesn’t stick to the drum are some of these type of machines’ features. Besides driveways, biking paths, and pothole repair, these machines are spot-on for such uses. They are incapable of generating enough pressure needed by high traffic roads however.

Do I require a driving license to operate a ride-on roller?

Operating heavy machinery such as a ride-on roller in a public area mostly requires the operator to have a driving license and sometimes even a heavy equipment operator’s certification in many regions. On private sites, even though government-regulated licenses might not be mandatory, a certification (like OSHA certification in the US) from the employer or insurance company is usually required to guarantee safety.

Which roller is safe for trench work?

Among the two choices of rollers, a walk-behind type particularly one with a remote control (a trench roller) is much safer. Because it doesn’t require the worker to be physically present inside the trench during compaction, it protects him/her from potential cave-ins and high noise levels. Generally, ride-on rollers are too wide for standard utility trenches.

What is the difference between single drum and double drum ride-on rollers?

Single drum rollers fitted with rubber tires at the back are primarily used for soil and gravel compaction; plus the tires provide good traction on loose terrain. … Double drum rollers (steel drums front and back) are solely meant for asphalt pavements application; here the two smooth drums help produce a flatter surface without tire marks.

Is there any maintenance difference?

More complex hydraulic systems, larger engines, and higher mileage parts like articulated steering joints and cab climate systems of ride-on rollers entail that maintenance cost/time will be higher compared to walk-behind rollers. Walk-behind rollers are plainer, fewer hydraulic lines and smaller engines, thus cheaper and less time-consuming to service it.

Can I operate a ride-on roller on a slope?

Yes, but extreme caution should be exercised. Ride-on rollers have a high center of gravity and can tip over, so you must follow the manufacturer’s specifications on gradeability (usually expressed in % slope) strictly. In the case of very steep slopes, the safer choice is either a winch-assisted roller or a remote-controlled walk-behind unit.

“Walk-Behind vs Ride-On Roller Compactors”, is it all about size?

No, type of compaction also matters. Walk-behind rollers (mostly trench rollers) on occasion use “padfoot” drums for deep lift compaction of cohesive soil (clay). Ride-on rollers also have padfoot types, but the vibratory mechanism of walk-behind trench rollers is specially designed to produce deep, intense compaction required in utility backfilling – which is quite distinct from wide-area surface compaction of a ride-on unit.

In Sum: Walk-Behind vs Ride-On Roller Compactors

There is no winner in the walk-behind vs. ride-on roller compactors fight—there’s only the right tool for the job. If your project involves narrow trenches, residential driveways, or areas with limited access, a walk-behind roller will be a wise investment for you in terms of agility and cost-effectiveness.

It provides precision and safety beyond the capability of larger machines. However, if not only speed but also acreage is your concern, then ride-on rollers are the necessarily powerful complement of the open ground or miles of asphalt whose density specs and deadlines you mustn’t miss.

Typhon Machinery advises you to come to a different conclusion at every job. Do not try to put a ride-on roller where it does not fit and do not exhaust yourself while paving a parking lot with a walk-behind unit. Get to know each very well, and you will raise efficiency, safety, and profit.