2.5 Ton Mini Excavator

If you’ve spent any time in the dirt game—whether you’re a landscape contractor, a plumber chasing sewer lines, or a general contractor managing residential builds—you know that the equipment you choose dictates your profit margin. Buy too small, and you’re spending three days on a one-day dig. Buy too big, and you’re tearing up the client’s driveway and spending a fortune on heavy haulers.

Enter the 2.5-ton mini excavator.

In my twenty years of operating heavy iron, I have come to the conclusion that this specific weight class is the absolute “sweet spot” for 90% of residential and light commercial work. It is the machine that bridges the gap between a toy and a tank. It has the grunt to rip out tree stumps and tackle tough clay, but the finesse to work next to a retaining wall without knocking it over.

This guide isn’t just a spec sheet. It’s a deep dive into why this machine is likely the most profitable tool you can add to your fleet this year. We are going to look at the real-world capabilities, the logistics of hauling, the operator experience, and the bottom-line numbers.

The Logistics Advantage: Why Size Matters

Before we even talk about digging, we have to talk about getting the machine to the job. This is where the 2.5 ton mini excavator wins the battle before the engine even starts.

If you step up to a 3.5-ton or 5-ton machine, you are suddenly entering a different world of logistics. You’re looking at Commercial Driver’s Licenses (CDL), massive dump trailers, and heavy-duty dually trucks. That’s a lot of overhead.

Typically, the 2.5-ton class weighs between 5,500 and 6,000 lbs. When you add a standard trailer, you are often still comfortably within the towing capacity of a robust ½-ton pickup or a standard ¾-ton truck. For a small business owner, this advantage is massive.

Site Access: The Tight Squeeze Specialist

Urban density is increasing. Property lines are shrinking. The days of having wide-open access to a backyard are gone.

A standard compact excavator in this class is usually around 5 feet wide (roughly 60 inches). Most residential gates are either 36 inches (too small for anything but a micro) or 6 feet (double gates). The 2.5-tonner slides right through those double gates.

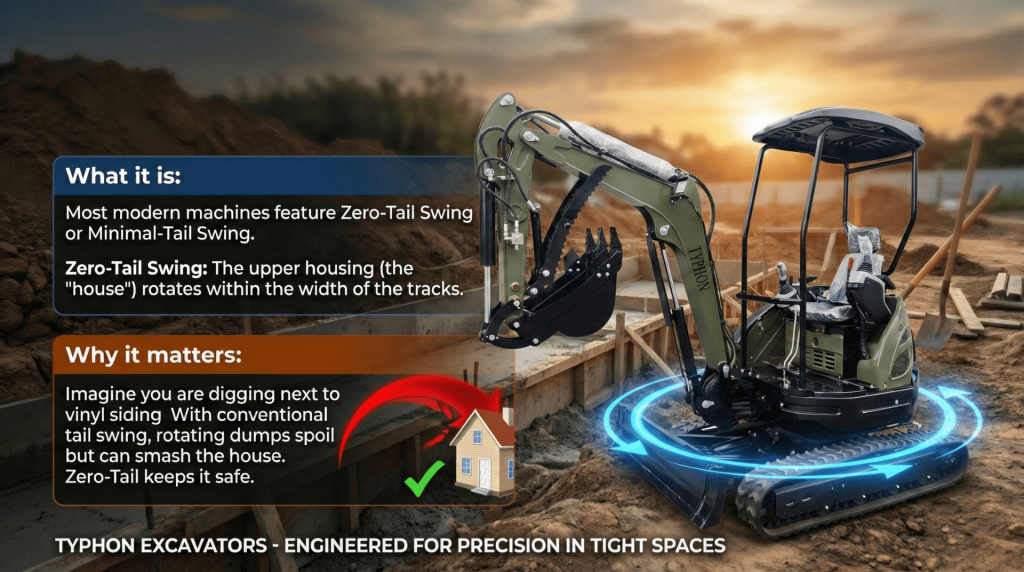

Furthermore, most modern machines in this class feature Zero-Tail Swing or Minimal-Tail Swing.

- Zero-Tail Swing: This means the upper housing (the “house”) rotates within the width of the tracks.

- Why it matters: Imagine you are digging a footer right next to a client’s brand-new vinyl siding. With a conventional tail swing, every time you rotate to dump your spoil, the back of the machine swings out. One slip-up and you’ve smashed the house. With a zero-tail 2.5-ton machine, if your tracks fit, you fit. You can focus on the bucket, not the bumper.

Detailed Analysis: Power vs. Weight

Let’s get technical. Many guys think, “It’s small, so it must be weak.” That used to be true twenty years ago. Today, hydraulic technology has advanced to the point where these machines are punching way above their weight class.

The Digging Geometry

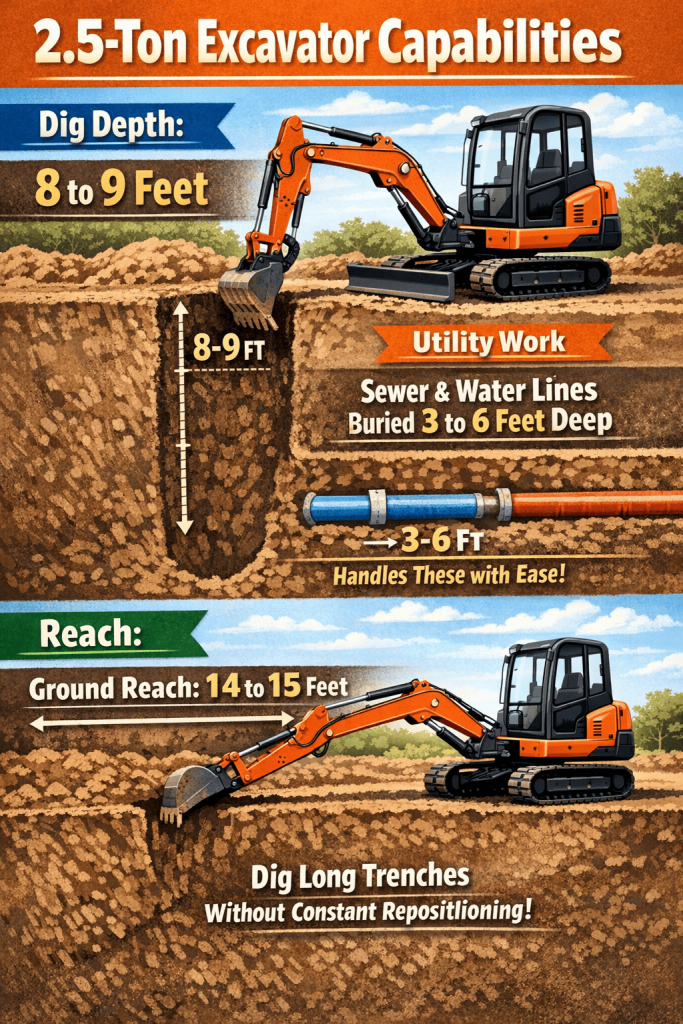

A quality 2.5-ton machine will typically give you a dig depth of around 8 to 9 feet.

- Utility Work: Most sewer lines and water mains in residential areas are buried between 3 and 6 feet deep. This machine handles that with ease, leaving you plenty of buffer room.

- Reach: You usually get a ground reach of about 14 to 15 feet. This allows you to dig a substantial trench without having to reposition the tracks every two minutes.

Breakout Force Explained

When looking for a mini excavator for construction, pay attention to “Bucket Breakout Force.” In this class, you should expect around 5,000 to 6,000 lbs of force.

To put that in perspective: That is enough force to rip through 6-inch tree roots, pry up concrete sidewalks, and dig through “caliche,” or compacted clay. The hydraulic pumps on these modern units are high-flow, meaning you can curl the bucket and boom up simultaneously without the functions fighting each other.

Comparative Analysis: Finding the Right Class

To help you visualize where the 2.5-ton fits in the market, I’ve put together this comparison table based on typical job site scenarios.

Table 1: The Excavator Class Showdown

| Feature | 1-Ton “Mini” Excavator | 2.5-Ton Compact Excavator | 3.5-Ton+ Mini Excavator |

| Transport | Fits in a truck bed or small utility trailer. No brakes are needed usually. | Tows easily with a standard pickup & landscape trailer. | Requires heavy-duty truck (1-ton dually) & CDL often required. |

| Access Width | Ultra-narrow (retractable tracks <30″). Fits through front doors. | Standard ~60″ width. Perfect for fence gates. | Wide (>66″). Too wide for many residential backyards. |

| Digging Depth | Limited (5-6 ft). Surface work, irrigation. | Deep enough for mains, septics & basements (8-9 ft). | Deep digging (10ft+), commercial grade. |

| Stability | Feels “tippy” with heavy loads/swinging. | Solid footprint. Handles heavy clay & rocks well. | Very stable, but the heavy footprint damages turf. |

| Operator Cab | Usually open ROPS (roll bar) only. | Often available with a full AC/heat glass cab. | Standard full cab comfort is the norm. |

| Ideal For | Indoor demo, doorways, tight alleys. | Landscaping, Utilities, Driveways, and Retaining Walls. | Roadwork, large commercial sites, heavy excavation. |

As you can see, the small excavator for landscaping in the 2.5 ton range offers the best compromise. It isn’t a toy, but it isn’t a logistical burden.

Versatility: It’s Not Just a Bucket, It’s a Robot

If you are buying this machine just to dig holes with a bucket, you are wasting 50% of its potential. The modern 2.5 ton excavator is a hydraulic tool carrier.

1. The Hydraulic Thumb (The Must-Have)

I cannot stress this recommendation enough: Get the thumb.

A hydraulic thumb clamps down against the bucket. It turns your excavator into a hand.

- Demolition: You can grab a piece of concrete, lift it, and place it gently in the truck rather than dropping it.

- Land Clearing: You can pluck scrub brush and small trees right out of the ground, shake the dirt off the roots (saving dump fees), and stack them neatly.

- Rock Walls: Building a boulder retaining wall with a thumb is an art form. You can pick up a rock, rotate it, and set it with puzzle-piece precision.

2. The Grading Blade

The dozer blade on the front isn’t just for pushing dirt. It’s your stabilizer.

- Pro Tip: When you are digging in hard ground, drop the blade and lift the front of the tracks about 2 inches off the ground. This transfers the weight to the blade and the rear tracks, creating a solid, non-rocking platform.

- Backfilling: With a 2.5-tonner, the blade is wide enough to cover your tracks. You can backfill a trench efficiently. Some premium models even offer an “angle blade” that allows you to windrow dirt to the side, though that adds to the mini excavator price.1

3. Augers and Breakers

Need to drill 50 post holes for a privacy fence? Pop the bucket off (which takes 30 seconds with a quick coupler) and put on an auger drive. You’ll drill a 4-foot-deep hole in tough soil in under a minute.

Need to remove an old patio? Hook up a hydraulic hammer (breaker). The 2.5-ton machine has enough down-pressure to drive a breaker effectively through reinforced concrete.

The Operator Experience: Comfort Equals Productivity

I’ve spent thousands of hours in the seat. I can tell you that a comfortable operator is a profitable operator. If your back hurts and you’re sweating to death, you work slower.

The Cab: Cab vs. Canopy

This is the big debate.

- Open Canopy (ROPS): Cheaper, better visibility, easy to hop in and out of. Great for landscapers who are constantly on and off the machine checking grades.

- Enclosed Cab (HVAC): More expensive, but allows you to work in any weather. Rain, snow, or 100-degree heat—you are inside in a climate-controlled bubble. If you work year-round, the cab pays for itself because you don’t have to shut down when the weather turns.

Controls: Pilot vs. Mechanical

Old-school machines used mechanical levers linked directly to the valves. They were jerky and heavy.

Modern 2.5-ton machines use pilot controls. These are hydraulic or electronic joysticks. They require very little effort. You can operate them with your fingertips.

- Pattern Selector: Most machines now come with a pattern changer valve. This lets you switch between “ISO” (Excavator pattern) and “SAE” (Backhoe pattern).3 This is crucial if you have different operators who learned on different machines.

Engine & Maintenance

Construction equipment lives a tough life. It eats dust, mud, and gravel. The engineering behind these compact machines focuses on durability.

The Power Plant

You will usually find a 3-cylinder or 4-cylinder diesel engine in this class (Kubota, Yanmar, Perkins, etc.)

- The 25 HP Threshold: This is a key regulatory detail. Engines under 25 horsepower are generally exempt from the strictest Tier 4 Final emissions regulations that require Diesel Particulate Filters (DPF) and DEF fluid.

- Why this is good: DPF systems can clog if the machine idles too much, requiring a “regen” cycle that stops work. By staying under 25 HP, the 2.5-ton machine avoids this headache. It’s simpler, cleaner, and cheaper to maintain.

Maintenance Checklist

When you are looking at a machine, verify the access.

- Grease Zerks: Are they easy to reach? The boom swing pin is notorious for being neglected because the zerk is hidden. Good designs make these visible.

- Tracks: You generally have a choice between rubber and steel.

- Rubber Tracks: Standard on this size. They don’t damage driveways or turf.

- Steel Tracks: Rare on 2.5-tonners, but better for jagged rock demolition sites.

- Cooling: Check the radiator screen. These machines work low to the ground where dust and dandelion seeds float. A good machine has an easy-to-clean slide-out screen.

Understanding the Financials: Mini Excavator Price and ROI

Now, the part that matters to your bank account. How much does it cost, and how does it make money?

New vs. Used Pricing

- Premium Brands (Cat, Kubota, Bobcat, Deere): A new 2.5 ton unit with a cab and thumb will run you anywhere from $45,000 to $60,000. These hold their value incredibly well.

- Direct-to-Consumer/Import Brands: The market has been flooded recently with machines in the $20,000 to $30,000 range. These can be great starter machines, but you must verify parts availability. A cheap machine is effectively a paperweight if you can’t get a replacement hydraulic pump.

The ROI Calculation

Let’s perform some simple calculations.

- Rental Cost: Renting a 2.5 ton machine typically costs about $350 – $450 per day (plus delivery fees).

- Ownership Cost: If you finance a $40,000 machine over 5 years, your payment might be around $800/month.

If you use the machine for three days a month, you have paid the monthly note. Everything after that is profit.

Plus, there is the “convenience factor.” When you own the machine, you can take small jobs—like digging a 2-hour trench for a neighbor—that wouldn’t be worth the hassle of renting. You become more agile.

Resale Value

High-quality mini excavators depreciate slowly. It is not uncommon to buy a machine, put 1,500 hours on it over 3 years, and then sell it for 75–80% of what you paid. When you factor that in, the actual “cost” of owning the machine is very low compared to renting.

Real-World Applications Checklist

To wrap this up, here is a quick list of jobs where the 2.5 tonner dominates. If you do any of these, this machine is for you.

- Foundation Waterproofing: Digging along the foundation of a house to repair cracks.

- Septic Install: Digging the tank hole and the leech field lines.

- Pool Prep: Digging out for fiberglass or vinyl liner pools in tight backyards.

- Hardscaping: Moving pallets of pavers and large landscape boulders.

- Brush Clearing: Removing invasive species like honeysuckle or buckthorn.

- Driveway Prep: Removing topsoil and spreading gravel base.

Final Verdict: The Professional’s Choice

The 2.5 ton mini excavator isn’t just a purchase; it’s a partner. It’s the machine that saves your back, speeds up your schedule, and impresses your clients.

It offers the perfect balance of power and portability. It’s big enough to get the job done right but small enough to get the job done anywhere. Whether you are an established construction firm looking to add a versatile support machine or a landscaper ready to stop renting and start building equity, this excavator is the answer.

Stop digging by hand. Stop waiting on rental deliveries. Take control of your job site with a machine built to work as hard as you do.