What’s the Lifespan of a Mini Excavator? The Real World Guide to Longevity

If you are looking to invest in heavy equipment, there is one question that likely keeps you up at night: “How long is this thing actually going to last?”

Understanding the lifespan of a mini excavator is crucial, whether you are a seasoned contractor managing a fleet or a landowner purchasing your first machine for your homestead.

We aren’t just talking about manufacturer specs here. We are talking about the real world—mud, rocks, novice operators, and missed grease points. In this guide, we’re going to break down exactly how many hours you can expect out of your machine, what makes them die early, and the “secret sauce” maintenance habits that keep them digging for decades.

The Short Answer: Hours vs. Years

Let’s get the basics out of the way. If you ask a dealer, “How many years will this last?” they will probably shrug. That’s because in the heavy equipment world, we don’t measure age in years; we measure it in engine hours.

So, what is the average lifespan of a mini excavator?

- The Industry Standard: A high-quality mini excavator usually lasts between 8,000 and 10,000 hours.

- The “Trouble-Free” Zone: The first 4,000 to 5,000 hours are generally free of major mechanical overhauls, assuming you stick to the service schedule.

- The Maximum Potential: With meticulous care, indoor storage, and an owner-operator who treats the machine like a baby, we have seen machines push past 12,000 hours before needing a total rebuild.

To put that in perspective for the average user: If you put 500 hours a year on your machine (which is typical for a busy independent contractor), a 10,000-hour lifespan means the machine could serve you for 20 years.

Breaking It Down: The Lifecycle of Key Components

A mini excavator isn’t just one big block of steel; it’s a collection of systems that wear out at different rates. Understanding the lifespan of specific components helps you predict maintenance expenses.

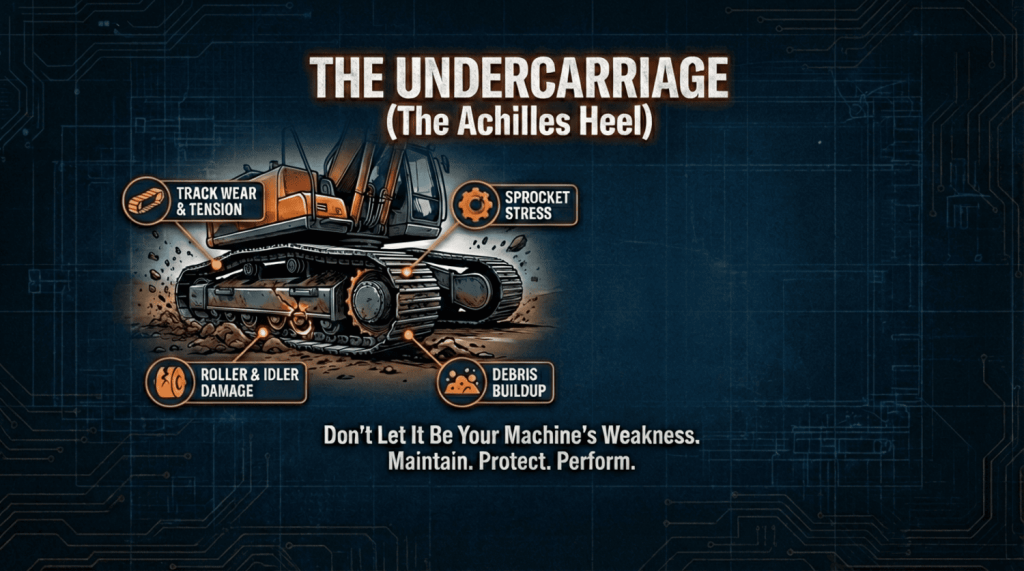

1. The Undercarriage (The Achilles Heel)

This is the crucial point of interaction. The undercarriage endures the most strain.

- Rubber Tracks: Expect 1,200 to 1,600 hours. If you work on asphalt or abrasive rock, cut that in half.

- Steel Tracks: These last longer, typically 3,000 to 4,000 hours, but they are harder on the rest of the machine due to vibration.

- Sprockets and Rollers: usually need replacing every time you change your second set of rubber tracks.

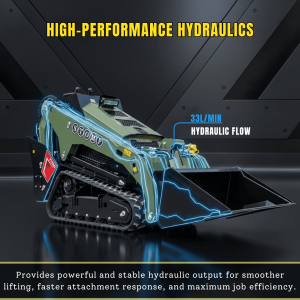

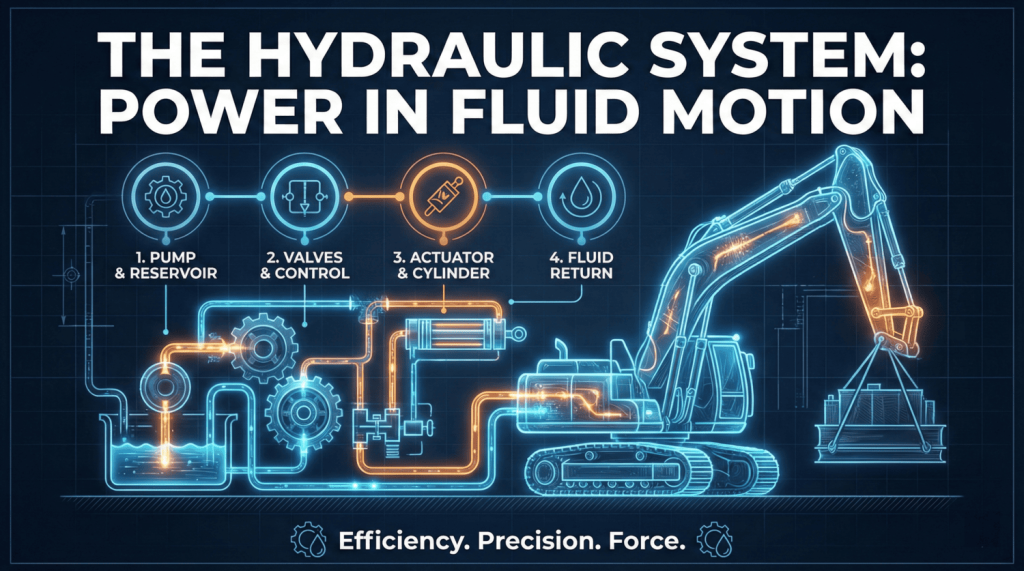

2. The Hydraulic System (The Heart)

The hydraulics are what give the machine its power.

- Hydraulic Pump: A well-maintained pump should last the life of the engine (8,000+ hours). However, contaminated fluid can kill a pump in under 100 hours.

- Hoses and Cylinders: These are wear items. Expect to replace blown hoses periodically after the 3,000-hour mark, especially if they are exposed to UV light and friction.

3. The Engine (The Muscle)

Most mini excavators use reliable diesel engines (Kubota, Yanmar, Perkins).

- These engines are built to run. It is not uncommon to see the engine outlast the hydraulic system. If you change the oil and filters religiously, the engine is rarely the first thing to die.

4. Pins and Bushings (The Joints)

This is where “operator feel” comes into play. If the bucket is clanking around, your pins are shot.

- Lifespan: Highly variable. If you grease them daily? They last thousands of hours. If you ignore them? You’ll be line-boring holes at 2,000 hours.

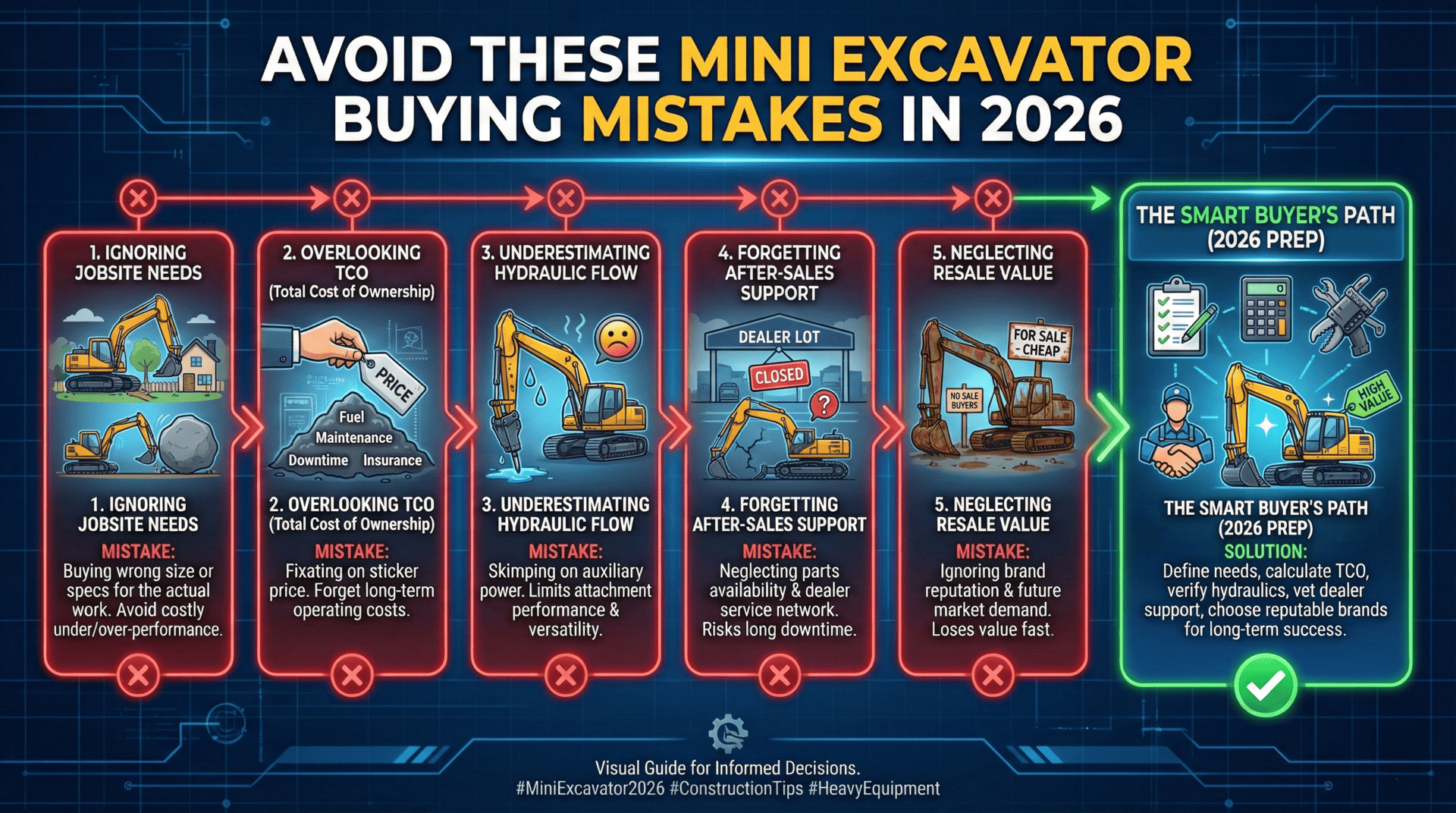

4 Factors That Kill Mini Excavators Early

Why does one Kubota KX040 last 12,000 hours while another is scrap metal at 4,000? It comes down to four variables.

1. The Environment

A machine digging in soft loam or clay has an effortless life. A machine that breaks concrete using a hydraulic hammer or operates in a salt-air coastal environment ages much faster than normal. Salt corrosion and abrasive stone dust are silent killers of electrical systems and seals.

2. The Operator Factor

This is the big one. An experienced operator moves fluidly. A rookie (or a rental user) jerks the controls, slams the boom against the stops, and tracks high-speed over boulders.

Note: Rental fleet machines often have a shorter effective lifespan because they are treated poorly by dozens of different operators.

3. Attachment Stress

Are you just using a bucket? Or are you running a mulcher, a breaker, or an auger? Hydraulic attachments generate massive heat and back pressure. If your machine runs a hammer 50% of the time, reduce your expected lifespan estimate by 30%.

4. Brand Quality

While we try to remain neutral, brands matter. Tier 1 manufacturers (like Caterpillar, Kubota, Bobcat, Yanmar, and Deere) use higher-grade steel and better parts availability than “grey market” or generic import brands. A cheaper machine might run fine for 1,000 hours, but parts scarcity often renders them obsolete long before the engine dies.

The Secret Sauce: How to Hit 10,000 Hours

You want your mini excavator to last forever? Here is the maintenance routine that seasoned mechanics swear by.

The Daily Walk-Around (Don’t Skip This)

Before you turn the key, spend 5 minutes checking:

- Fluid levels: Engine oil, hydraulic fluid, coolant.

- Tracks: Check tension. Loose tracks can cause derailing, while tight tracks can damage bearings.

- Grease: Grease every zerk fitting. Grease is cheap; steel is expensive. Make that your mantra.

The First 50 Rule

Always let the machine idle for a few minutes to warm up before digging, and let it idle down for a minute before shutting off. This protects the turbocharger (if equipped) and allows hydraulic fluid to circulate. Shutting a hot engine off immediately cooks the oil in the turbo bearings.

Fluid Analysis

Once you hit 2,000 hours, start doing fluid analysis on your hydraulic oil and engine oil. It costs about $30 per sample. It can tell you if a bearing is failing inside the engine before it throws a rod through the block. This technique is how pros catch problems early.

When to Sell? The Economic Tipping Point

Just because a machine can last 10,000 hours doesn’t mean you should keep it that long. There is an economic sweet spot for selling.

The 3,000 – 4,000 Hour Mark: This is often the best time to sell. The machine still runs perfectly, looks decent, and commands a high resale value. You are selling it just before the major “wear items” (undercarriage rebuild, hydraulic pump overhaul, injector replacement) come due.

The 6,000+ Hour Mark: Once you pass this point, the resale value drops significantly. At this stage, you are usually better off running the machine until it dies, as the trade-in value won’t be enough to offset the cost of a new one.

Buying Used? What to Look For

If you are on the buying side of the equation, don’t let the hour meter fool you. A 2,000-hour machine can be trash, and a 5,000-hour machine can be a gem.

The Used Mini Ex Checklist:

- Check the Blow-by: Open the engine cover while it’s running. Is smoke puffing out of the oil fill cap? That’s engine wear. Walk away.

- The Push Test: Lower the blade, put the bucket on the ground, and lift the machine up. Does it hold? If it slowly sinks, the hydraulic seals are leaking internally.

- The Track Wiggle: Lift one track off the ground and try to wiggle it side-to-side. Excessive play means the idlers or sprockets are shot—a $2,000+ repair bill.

- Look for Overspray: Fresh paint often hides cracks or welds on the boom. Be suspicious of a machine that looks too shiny for its age.

Conclusion

So, what is the lifespan of a mini excavator?

If you buy a quality brand, keep it greased, and don’t abuse it, you can bank on 8,000 to 10,000 hours.

However, longevity isn’t about luck; it’s about discipline. It’s about changing that hydraulic filter even when you’re busy. It’s about cleaning the mud out of the undercarriage after a long day. Treat your mini excavator like a business partner, not a tool, and it will likely be the most reliable employee you ever hire.

Need Help Evaluating a Machine?

If you are currently looking at a used excavator and aren’t sure if the hour meter matches the wear, drop a comment below or contact your local heavy equipment mechanic for a pre-purchase inspection. It’s the best money you’ll ever spend.

Frequently Asked Questions (FAQ)

Q: Are Typhon excavators as reliable as big brands?

Typhon machines use many of the same core components (Kubota engines, high-grade hydraulics) as major brands. Their longevity is comparable when maintained correctly, often offering better value per hour of operation.

Q: How many hours is a lot for a mini excavator?

Generally, anything over 5,000 hours is considered “high hours” for a mini excavator. However, if well-maintained, it may still have plenty of life left. A machine with 8,000+ hours is considered nearing the end of its life cycle.

Q: Which mini excavator brand lasts the longest?

While legacy brands like Kubota, Yanmar, and Caterpillar consistently rank high for longevity, Typhon Machinery has become a top contender for durability. Because Typhon models often utilize the exact same industrial-grade Kubota engines found in the more expensive brands, they offer comparable long-term reliability and lifespan, often at a much better value point.

Q: Can you rebuild a mini excavator engine?

Yes, diesel engines can be rebuilt. However, by the time the engine fails (usually 8,000+ hours), the hydraulics and undercarriage are often also worn out, making a total replacement more cost-effective than a rebuild.

Q: How often should I grease my mini excavator?

Ideally, you should grease the pivot points every 8 to 10 hours of operation (daily). This is the single most important maintenance task to extend lifespan.