Choose the proper mini excavator might be difficult. Having so many choices might be overwhelming. This guide helps. We simplify choosing the right mini excavator for your requirements. This handbook is for building professionals, landscaping company owners, and consumers.

Mini excavators are adaptable. They’re utilized in gardening, building, demolition, and personal usage. Not all mini excavators are equal.

Different models have different characteristics. These may drastically affect performance and project appropriateness. Let’s begin.

Understanding Mini Excavators—Prominent Uses

Mini-excavators are smaller than conventional ones. Small, nimble equipment is its purpose. Small and nimble, they can operate in small locations where heavier equipment cannot.

These devices excel in many fields. Many work sites use mini excavators for trenching and demolition. Urban locations with limited space benefit from them.

Mini excavators are employed throughout sectors. Their typical applications include:

- Tasks related to landscaping and gardening

- Small-scale demolition ventures

- Install and maintain utilities

- Work in agriculture and forestry

- Site preparation and leveling

Each work benefits from the mini excavator’s accuracy and compactness. Landscapers like its ability to traverse gardens without hurting them. Utility personnel use it for trenching and pipeline construction.

Projects have a lower environmental impact with efficient design. This makes mini excavators viable for many. Due to their fuel economy and little noise, contractors prefer these equipment. These criteria are critical for residential or sensitive settings.

Understanding mini excavator usage helps choose the best model for certain jobs. Knowing what these machines can perform helps you choose the right one for your project.

Advantages of Mini Excavators Over Larger Equipment

MINI excavators have several advantages over bigger ones. Their tiny design lets them function in tight locations without sacrificing power. They work well in spaces where bigger devices cannot.

Portable mini excavators are a key benefit. They may be transported without permissions or bulky vehicles, unlike bigger excavators. This mobility speeds up work site transfers and minimizes logistical time.

Mini excavators are also cost-effective. They use less gasoline owing to smaller engines, lowering operational expenses. Maintenance and repair costs are frequently reduced due to their simplified design. This saves operators and owners long-term.

Key Considerations for Selecting a Mini Excavator

Important factors to consider when buying a mini excavator. These variables will help you pick an excavator for your project and budget. Focusing on these may enhance workplace productivity. Consider operating weight and work site appropriateness. Mini excavators’ weight and size influence site accessibility. Fragile surfaces may not support heavy models.

Next, consider dig depth and excavator reach. A machine’s efficient digging depth and distance are affected. Matching capabilities to project demands saves costly delays. Engine power matters. It impacts machine performance and ruggedness. A powerful engine helps mini excavators employ attachments.

Hydraulic system efficiency matters too. A dependable hydraulic system enhances output. It affects function speed and flexibility. Also important is track material—rubber or steel. Track advantages vary by terrain and application. This choice impacts surface safety and traction.

Mini excavator selection factors include:

- Operating Weight

- Dig Depth and Reach

- Engine Power

- Hydraulic System

- Track type

Finally, consider operator comfort and safety. Comfortable operators work better and are less tired. Safety elements like ROPS (Roll Over safety Structure) enhance safety.

Operating Weight and Job Site Compatibility

Operating weight is crucial when choosing a mini excavator. Total machine weight includes accessories and operator. Operating weight affects machine-jobsite interaction.

Use a lightweight mini excavator for delicate or urban work. Heavy machinery may scratch delicate surfaces or struggle in tight places. Terrain and substrate type influence this option.

Additionally, operational weight impacts transit logistics. Lighter variants are simpler to transfer without permissions. This may save time and money on transportation.

Dig Depth and Reach: Matching Your Project Needs

Project compatibility requires dig depth and reach. How deep the excavator can dig affects foundation and utility work. Make sure the machine can reach your work depths.

Reach—arm distance from the cab—is also crucial. It controls the machine’s digging and loading capacity. Matching reach to project needs optimizes productivity and reduces repositioning.

The right dig depth and reach optimize performance. It improves job site workflow and operations. Review these specifications to meet project needs.

Engine Power and Performance

Engine power affects mini excavator performance. A strong engine improves efficiency and handles bigger loads. The equipment can also run in difficult situations without stalling.

Powerful engines support demanding attachments. It makes the machine more versatile and useful. For dependable operation, choose models with powerful engines for busy activities.

Increased power may increase fuel use. Power and efficiency must be balanced to control running expenses. Choose an affordable engine with enough power.

Hydraulic System Efficiency

Mini excavators need hydraulic efficiency. It makes boom, arm, and attachment functioning smooth. A strong hydraulic system boosts the machine’s versatility.

Mini excavators with improved hydraulics provide better control. Load-sensing hydraulics enhance power distribution. Fuel efficiency and wear & tear are improved by efficient systems.

Select a hydraulically better machine. This streamlines procedures and enhances productivity. Maximizing ROI requires efficient hydraulics.

Track Type: Rubber vs Steel

Rubber or steel rails affect machine performance. Rubber tracks decrease noise and protect surfaces. Residential areas that need ground preservation benefit from them.

Steel tracks improve traction and durability. They work in tough terrain and big construction sites. Steel rails are more stable on uneven areas but might harm fragile soils.

Choose track kinds based on your projects. Compare their benefits to find the best match. This choice may greatly impact machine performance and project success.

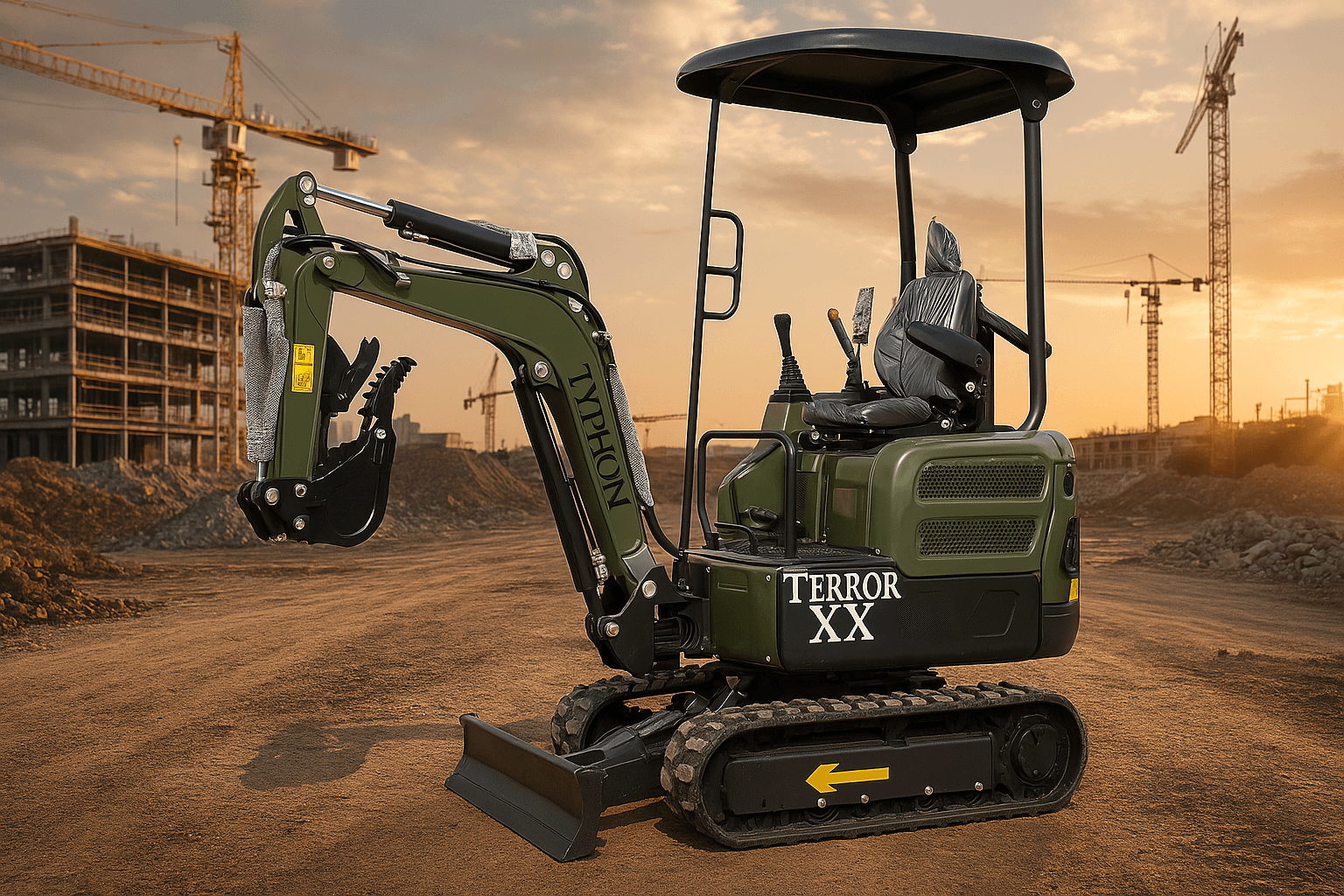

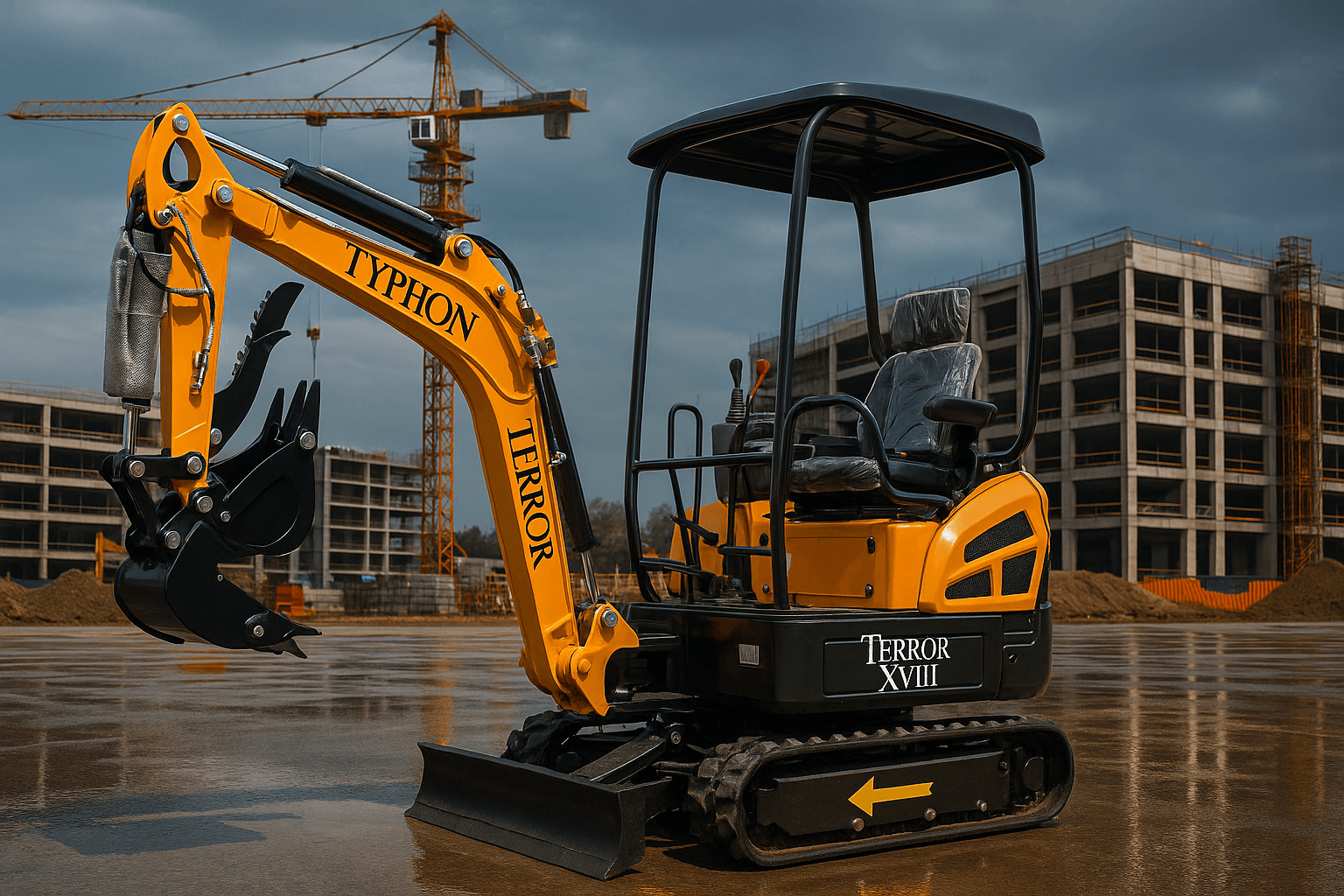

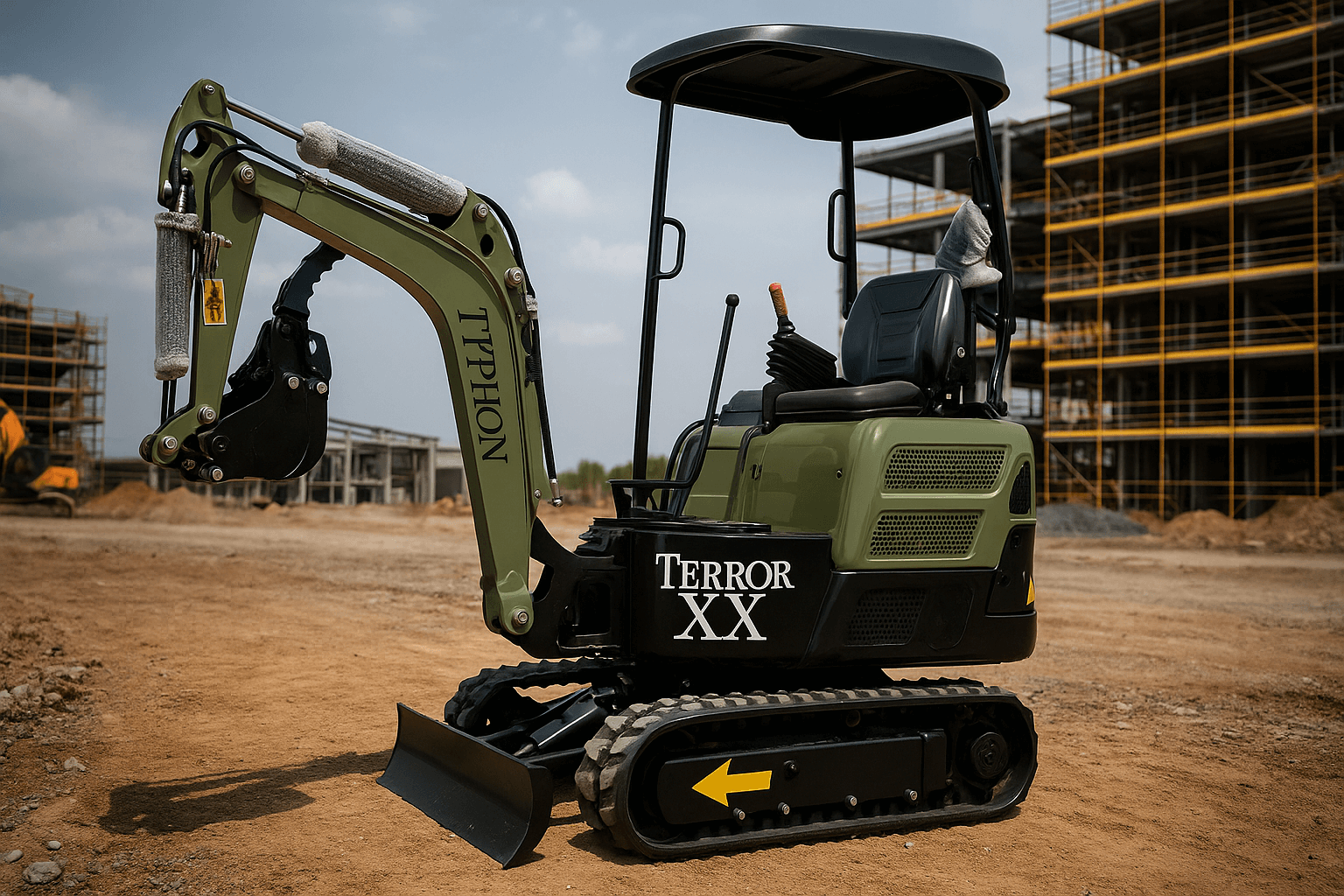

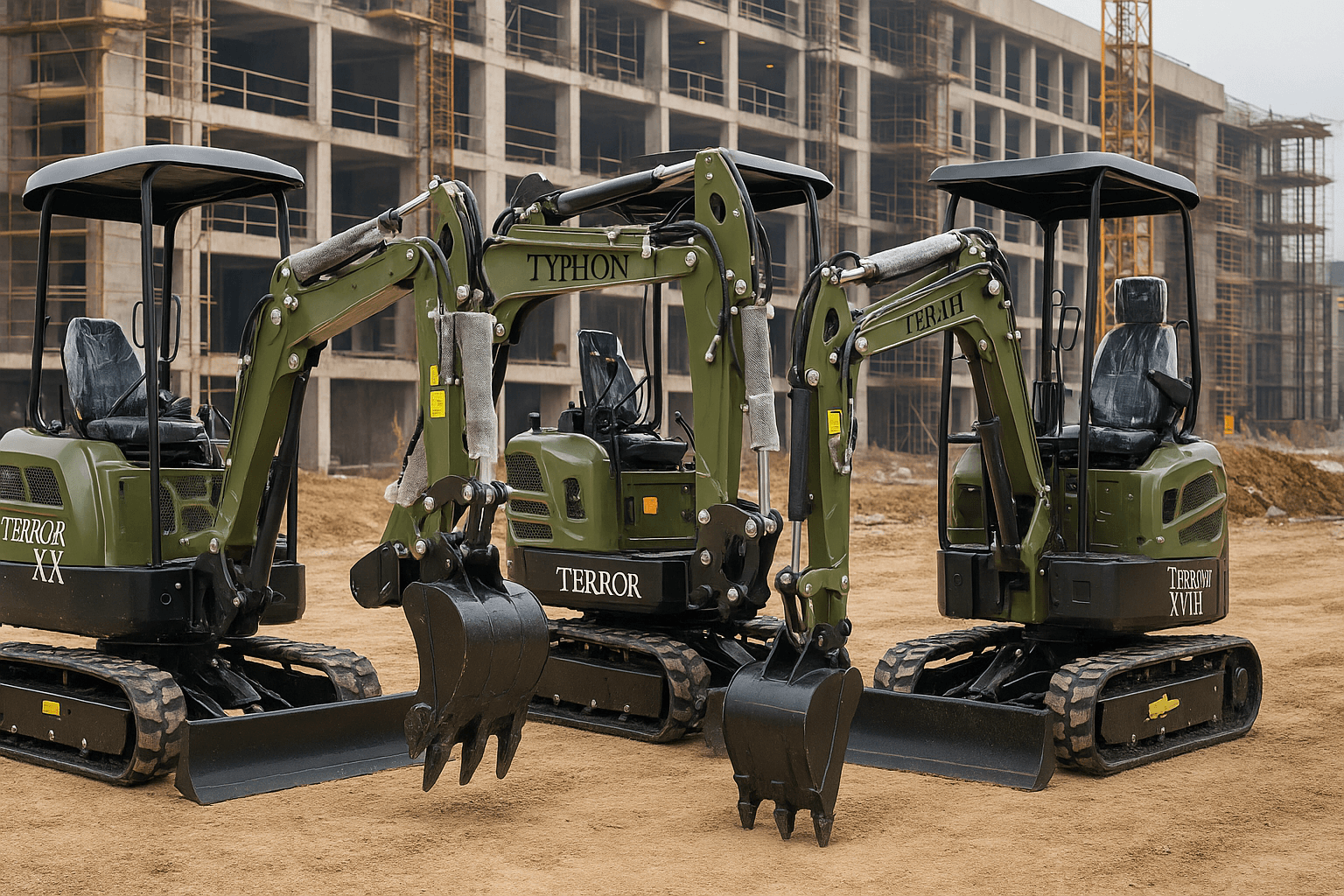

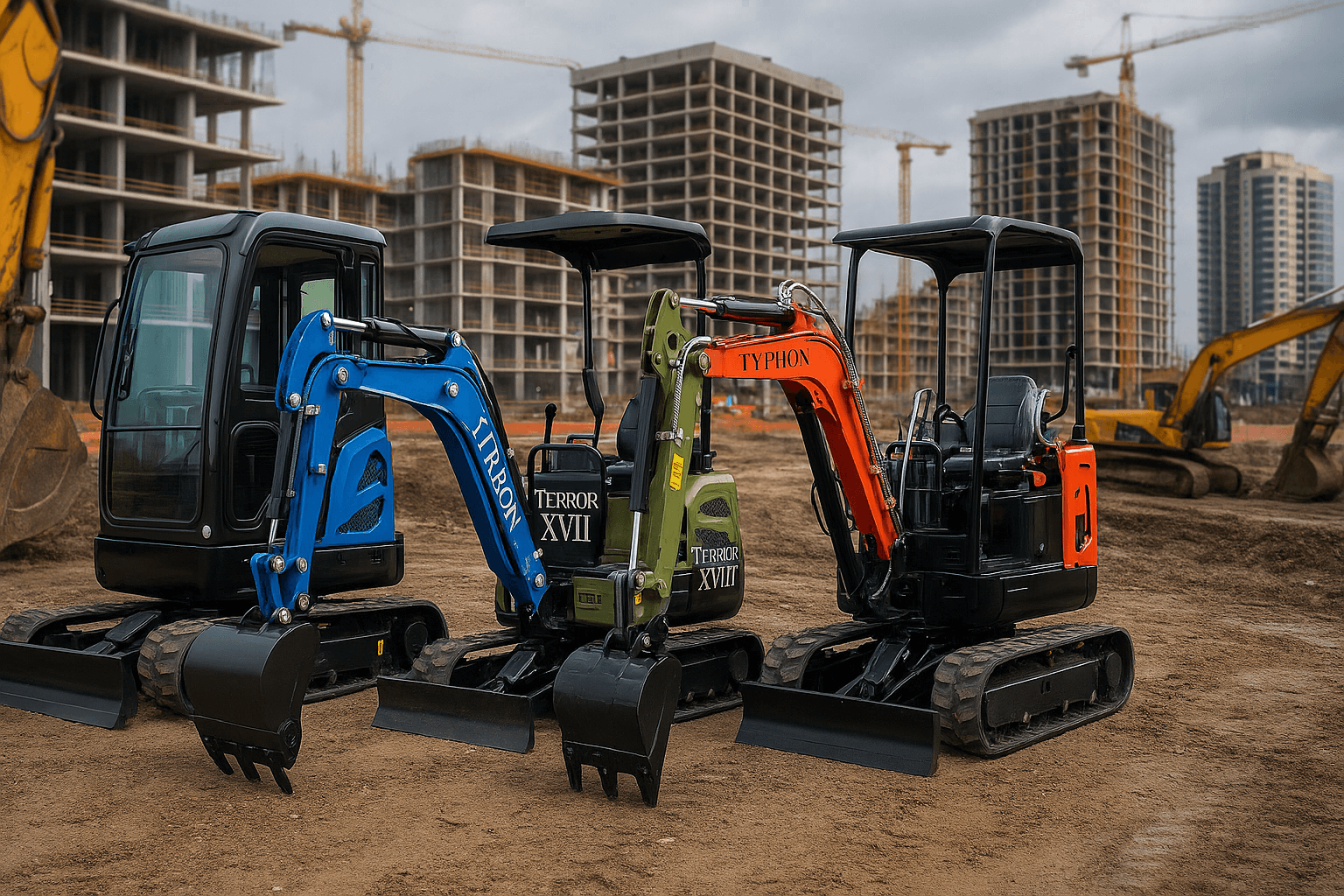

Mini Excavator Brand Comparison

Choose the best mini excavator for your job by brand reputation. Each brand has unique qualities for different uses. Knowing them may aid selection.

Mini excavators like Caterpillar, Bobcat, and Kubota are popular. These companies make reliable machines. Many options are available for different budgets and needs.

Prominent industry professionals pick Caterpillar for its powerful engines and innovative technology. Their mini excavators are tough enough for difficult conditions.

Bobcat’s portfolio is versatile. Their small size and mobility make these devices ideal for urban and constrained spaces.

Kubota’s engineering and fuel efficiency are great. Mini excavators with reliable hydraulics and simple controls are their expertise. They want comfort and performance.

Also consider Hyundai and John Deere. Competitive products from these firms may meet project demands. Feature and specification evaluation may aid customize choices.

Popular mini excavator brands are listed below:

- Caterpillar: Advanced technology and durability

- Bobcat: A compact and versatile design.

- Kubota: Fuel-efficient, user-friendly

- John Deere: Competitive features, dependability

- Hyundai: Affordable, gaining popularity

How Attachments Increase Functionality

Mini-excavators go farther. They have tremendous versatility with attachments. Mini excavators’ capabilities are considerably enhanced by these additions.

Augers, buckets, and breakers rule attachments. Each has a purpose. The auger may drill fence post or planting holes, while the bucket digs. Breakers break concrete well.

Quick couplers change attachments rapidly, reducing worksite downtime. This versatility lets one machine execute several tasks, improving efficiency.

Mini excavators have attachments for worksite purposes. The right addition may make your machine a grading and lifting powerhouse. Adaptability cuts equipment costs.

Comparison Considerations – Zero vs. Conventional Tail Swings

Mini excavators move via tail swing. Traditional or zero tail swing designs effect machine use.

Models with zero tail swing spin within track width. This makes them ideal for urban and constrained areas. Their small size lets them work near structures safely.

Traditional tail swings are more balanced and deeper. Since their tails extend beyond the tracks for operation, they may be better for wide areas.

Considering your usual work areas might help. Zero tail swings work in tight areas and regular ones in larger ones. This decision might significantly effect project safety and productivity.

Comfort and Safety for Operators

Comfort strongly impacts mini excavator productivity. Large cabs may keep drivers fresh. Operator happiness relies on ergonomic chairs and controls.

Mini excavators require safety features. Many models have ROPS/FOPS. These characteristics safeguard operators from mishaps in risky work environments.

Visibility affects comfort and safety. Visibility improves with big glass surfaces or 360-degree cameras. Accidents reduce as operator awareness increases, making workplaces safer.

Many current mini excavators offer configurable controls. Pattern control changers allow operators adjust ISO or SAE controls to taste. Personalization enhances comfort and reduces training time, allowing operators to perform securely and efficiently immediately.

Operating Costs and Fuel Efficiency

Fuel efficiency matters when purchasing a mini excavator. Fuel-efficient devices save money. This may save time, especially for heavy use.

Many mini excavators have fuel-efficient engines. Workload-dependent auto-idle and environmental modes control power. These methods cut fuel usage for simple tasks.

Budgeting requires understanding operating cost consequences. Gasoline, maintenance, and repairs should accompany equipment purchases. Fuel-efficient mini excavators are cheaper and more sustainable for long-term projects.

Model fuel consumption data is usually published by manufacturers. Comparing these values may help you choose the cheapest. Fuel-efficient cars save money and the environment by reducing emissions.

Costs Of Ownership, Maintenance, And Service

Mini excavators need regular maintenance to last. Regular maintenance prevents significant mechanical difficulties and guarantees reliability. Maintenance must be scheduled according to manufacturer guidelines.

Service point accessibility affects maintenance efficiency. Filters and fluids are easily accessible, making regular checkups quicker and easier. A well-designed machine lets technicians work without disassembling.

Ownership expenses exceed purchase price. Take into account spare parts, lubricants, and repair downtime. Since reliable machines reduce unexpected costs, they save money over time.

Proper maintenance influences machine resale value. Equipment with a good service history costs more. When selling or trading in the equipment, keeping accurate maintenance records might help.

Renting vs Purchasing: What’s Best for You?

You must evaluate your demands before renting or buying a mini excavator. For occasional use or short-term projects, renting may be cost-effective. This option lets you use the newest models without depreciation.

Those with regular or long-term needs may choose purchasing. Constant usage may lower equipment ownership costs. You may personalize your excavator with attachments for your tasks when you own.

Ownership has duties. Maintenance, storage, and insurance are important expenditures. Renting usually includes these services, reducing operational issues and downtime.

Analysis of project schedules and financial restrictions should inform your selection. Consider the entire expense of owning vs the ease of renting. Assess your requirements, finances, and goals to choose the best commercial or personal project route.

Inspection Tips Before Buying a Mini Excavator

Check the excavator before buying. Check the machine’s exterior for corrosion or damage. The undercarriage supports the machine’s weight and wears heavily.

Next, assess the performance-critical hydraulic system. Listen for odd arm and bucket sounds. Test controls to guarantee smooth and predictable operation.

Check the service history if available. Frequent maintenance may indicate a healthy equipment. However, significant repairs may be suspicious. If unsure, ask a professional inspection.

Peace of Mind with Warranty and Dealer Support

Mini excavators with robust warranties may provide buyers piece of mind. Engine and hydraulic systems should be covered by a comprehensive warranty. Understanding the guarantee and covered items is crucial.

Dealer support is essential for equipment durability. Check the dealer’s responsiveness and dependability. Available help saves time and money during unforeseen failures.

Additionally, verify spare parts availability. A well-stocked dealer prevents part delays. A reliable dealer can improve your ownership experience by providing help and confidence.

Comparing Mini Excavators to Job Site Needs

Understanding your task site demands helps choose a mini excavator. Projects need different skills and standards. Assess the terrain and space first.

Compact variants with negligible tail swing may work best in confined places. They make navigating without striking obstructions easier. Consider if your location needs the excavator to operate near walls or buildings.

Also important is the soil or surface you’ll work on. Rocky or uneven terrain may need a stronger machine. Harder digging conditions need stronger equipment.

Consider transit logistics and accessibility last. Ensure your mini excavator can be conveniently moved to and from the site. These criteria should match project needs for best outcomes.

Environmental Concerns and Emission Standards

Equipment selection depends on environmental standards. Mini excavators nowadays must meet strict emissions criteria. This reduces environmental effect and follows local rules.

New mini excavators in several locations must meet Tier 4 criteria. These rules dramatically minimize hazardous emissions. Understanding these standards prevents legal complications and promotes sustainability.

Consider your machine’s environmental impact beyond emissions. Cost savings and environmental preservation depend on fuel economy. Eco-friendly models save money and the environment.

Buyer’s Checklist: Evaluating Different Models

Selecting a mini excavator requires careful consideration. Models vary in features and specs. These factors must be considered to obtain the right fit. Check the machine’s operational weight. Confirm compatibility with work site terrain and size. This affects excavator maneuverability and transport.

Be mindful of attachments. Test model compatibility using different tools. The correct accessories may boost the machine’s capabilities. Consider a pre-purchase examination. This anticipates problems. Prevent pricey maintenance surprises with an examination.

This simple checklist will help you evaluate:

- Operating Weight: Ensure Operating Weight is appropriate for your terrain and needs.

- Dig Depth & Reach: Does the depth and reach fulfill project requirements?

- Engine Power: Is the horsepower sufficient for the specified task?

- Compatible attachments: Can they hold relevant tools?

- Tail Swing Design: Consider the Tail Swing Design that fits your work site’s space.

- Fuel Efficiency: Will it be cost-effective over time in terms of fuel efficiency?

By carefully following this criteria, you may make a smart mini excavator purchase. Taking time to analyze each model helps you get the correct equipment for your project.

Financing Options and Budgeting for Your Mini Excavator

Plan for a mini excavator with a suitable budget. One must be well aware of financial alternatives. Many dealers provide reasonable financing for budgets. These programs might have low interest rates or extended payment terms to help relieve stress.

Renting provides benefits over buying. One may find free little excavators available. Companies could relocate money to other areas as leasing is less expensive than purchasing. Lease expiry may provide more modern models, which would be beneficial.

One must budget going beyond the purchasing cost. Think about gas, insurance, and maintenance. These will help you to complete your budget. Your mini excavator investment is profitable and sustainable without unanticipated financial trouble.

New vs Used Mini Excavators: Making the Right Choice

Both new and used mini excavators have advantages. New equipment has advanced technology and guarantees. Dependability and performance customers would like this.

- Used mini excavators cost less upfront. They make inexpensive, useful tools. They cater to light or thrifty users.

- Used tools may have hidden deterioration and a lower lifespan. Complete service records and inspections are crucial. This indicates machine condition and recommends buying.

- Your budget, project requirements, and long-term goals will decide this. Consider future costs like used model maintenance. Most investment success hinges on choices.

Technological Advancements and Future Trends

Technological developments in mini excavators are significant. These innovations boost safety, efficiency, and usefulness. GPS integration is revolutionary. Project planning and drilling are more accurate using GPS.

Automated mini excavators are emerging. Manufacturers incorporate semi-autonomous features. By automating repetitive tasks, these features reduce operator fatigue and enhance productivity.

Telematics are expanding. In real time, these technologies provide machine performance and usage. Fleet management remote monitoring provides optimal performance and prompt maintenance.

Future sustainability will impact the industry. Electric micro-excavators arise. These devices operate quietly and emit less. Mini excavators will become more flexible and eco-friendly as technology progresses.

Conclusion: Making an Informed Decision

Mini excavators need cautious selection. Assess project duties and requirements. This helps you choose the greatest specifications and features. Consider engine power, dig depth, and operating weight. These variables impact work site appropriateness and machine performance. Consider attachments for versatility.

Brand and model research matters. Compare prices and benefits of renting versus buying. Make an informed choice that maximizes value and efficiency for your needs by following these steps.