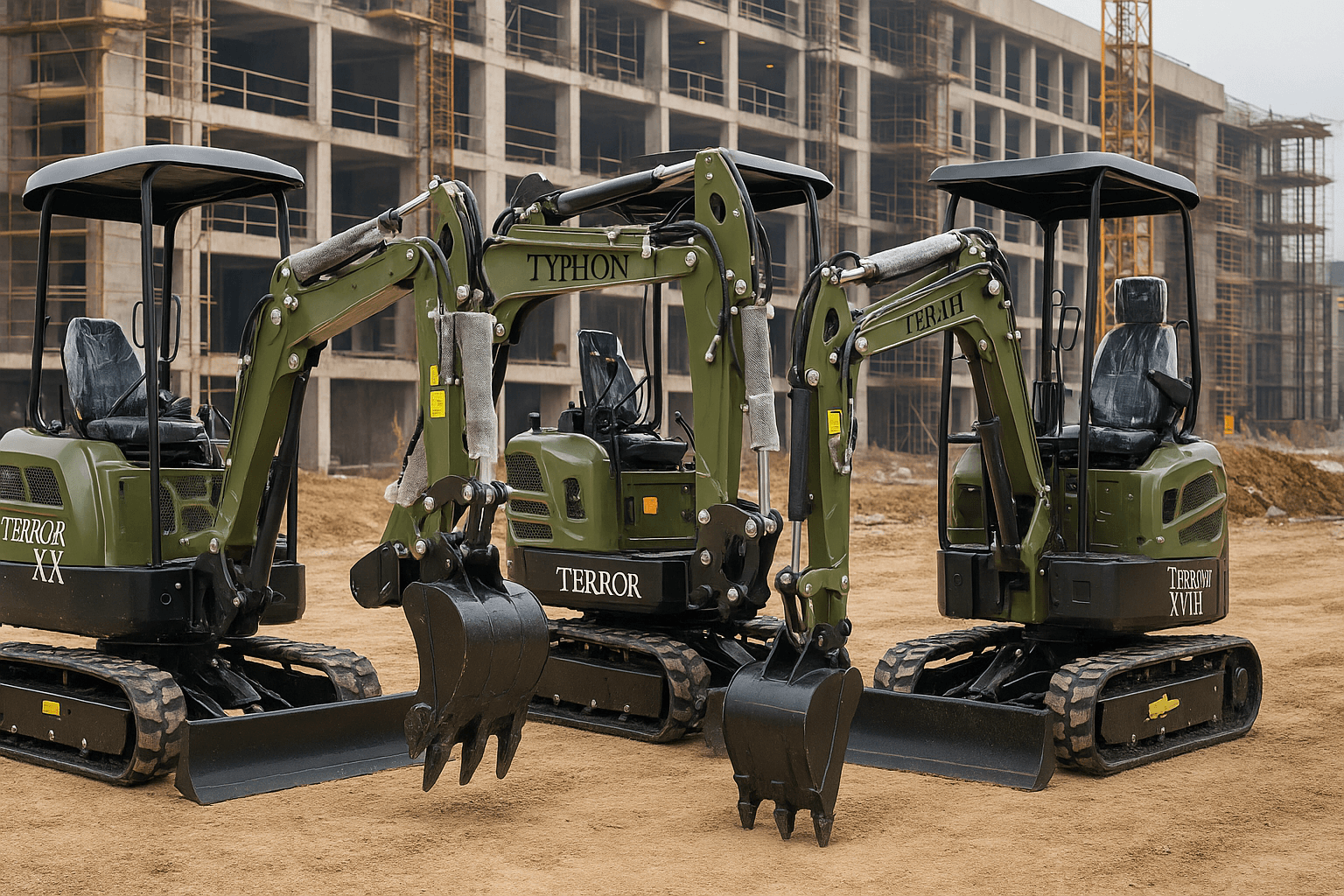

Mini Excavators Take Over Major Projects

Within the building industry, size is not necessarily everything. Mini excavators are demonstrating their versatility by easily handling large operations.

Small yet powerful, these devices are transforming the sector. They are demonstrating that, particularly in confined areas, smaller may sometimes be better.

Still, what gives mini excavators such flexibility? It’s not just their scale. Their breadth of attachments also lets them become multipurpose instruments.

For temporary jobs, leasing a mini excavator might be a reasonably priced fix. More businesses are renting mini excavators as this trend picks up steam.

This page will explore the realm of mini excavators. We will discuss their features, advantages of renting, and how they are significantly influencing a range of employment.

Thus, read on regardless of your level of expertise—construction or do-it-yourself. For your next job, you could discover that a mini excavator is just what you need.

The Mighty Mini: Knowing Mini Excavators

Unsung heroes on many project sites are mini excavators. They go over areas that leave conventional machines in struggle. Their modest size belies their adaptability, which makes them essential for many jobs.

What are Mini Excavators?

Compact tools used for material handling and excavating are mini excavators. Though little, they have a striking force. These machines fit different project requirements as their weights fall between one and ten tons.

Their mobility distinguishes them from more standard types. Where larger equipment cannot turn, mini excavators can. On crowded situations, their agility changes everything by allowing exact work without compromising strength.

The Force Driving the Compact Dimensions

Let their scale not mislead you. Designed for strength and efficiency, mini excavators are Their sturdy hydraulic systems provide the force required for demanding work. They are a preferred among operators visiting difficult places because of their authority.

Furthermore very good fuel economy do these machines provide. Reduced gasoline use results in less environmental impact and financial savings. Those who want to lower their carbon footprint without sacrificing performance will find them ideal.

Mini Excavators vs. Standard Excavators

Powerful but not always useful are traditional excavators. Mini excavators bridge the void and provide mobility and simplicity of use. For smaller projects, they provide comparable capabilities combined with convenience.

Mini excavators are user-friendly even if bigger excavators might scare. Learning to run them is faster, hence they are reachable for different degrees of expertise. Their architecture facilitates many jobs with less training required.

Often times, selecting a compact excavator results in lower running expenses. For many tasks, they are a sensible solution because less fuel and maintenance are required. They are great investments because of their cost-effectiveness and balanced of electricity.

Work Site Versatility with Regard to Excavator Attachments

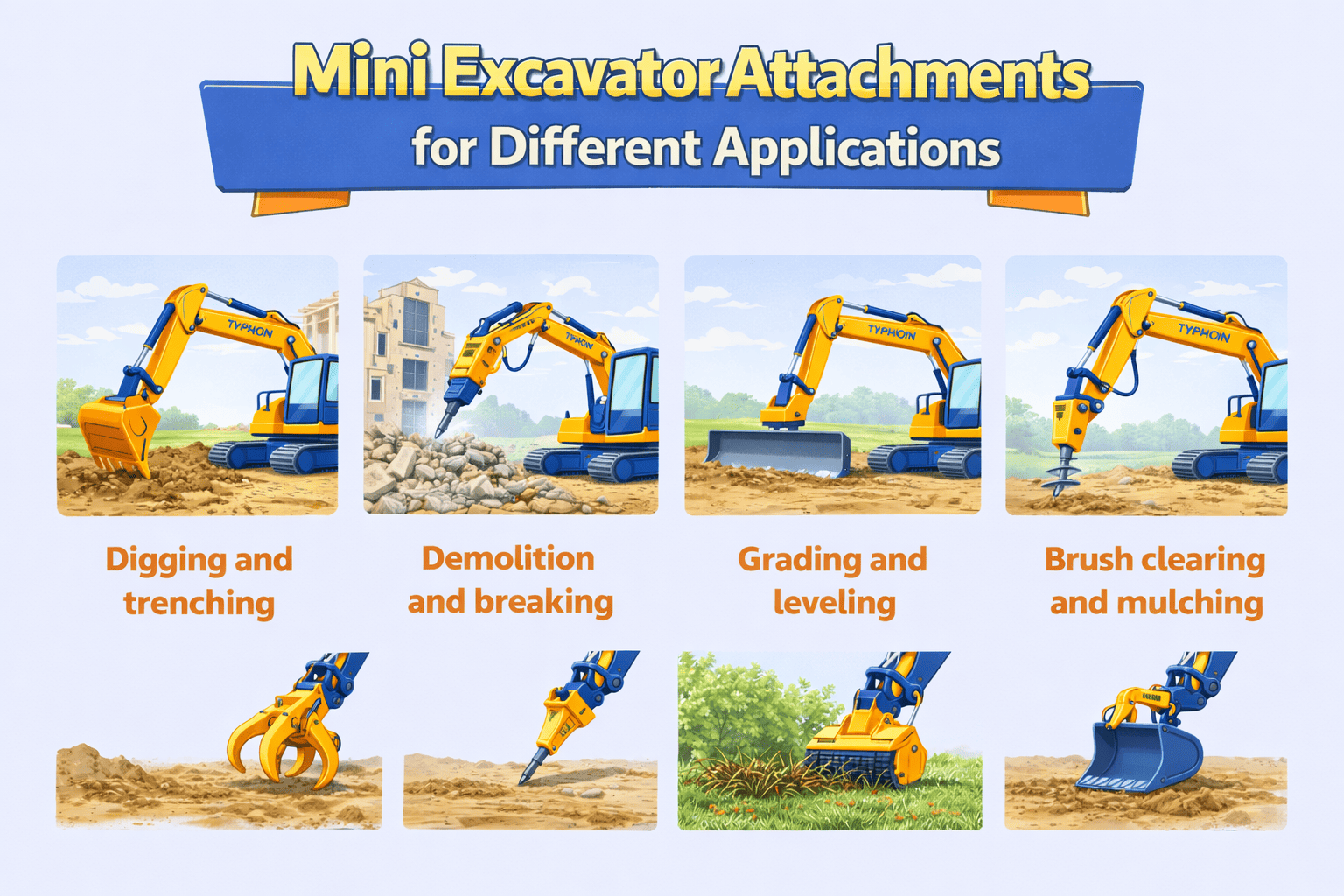

Attachments helps to handle the Mini excavators to be flexible and diverse. These gadgets turn them from basic diggers into multipurpose work horses. From gardening to demolition, there is a tool for every chore.

Attachments expand the capacity of mini excavators outside of excavation. They let drivers easily handle different jobs. Projects needing several purposes depend on this flexibility.

Moreover, using the correct attachment improves efficiency and saves time. This adaptability enables meeting of project targets without sacrificing quality. Task completion may be much improved with the correct instrument.

Many times, rental businesses provide a selection of attachments. This choosing guarantees that you have the correct instrument for every task. It streamlines the procedures, particularly for temporary projects.

Another rather cheap investment is in attachments. It makes best use of one machine, therefore lowering the need for more equipment. Small businesses and do-it-yourselfers would much benefit from this adaptability.

Typical References and Their Applications

Attachments improve the micro excavators’ performance. Common ones are listed here:

- Buckets: Perfect for excavating and shifting dirt.

- Augers: Perfect for ground hole drilling.

- Hammers: Applied in rock and concrete cracking.

- Graps: Perfect for logs and trash.

Different excavating demands call for different sized buckets. For jobs like fence post placement, augers streamline. With their great force, hammers save time on demolition tasks always outlook mini excavators market.

Grapples simplify lifting big objects. Every attachment serves a particular function, therefore extending the capabilities of the most popular mini excavators. Success of a project depends on choosing the correct one.

Customizing Your Mini Excavator for the Current Task

Task performance depends on customization. Choose attachments based on job-specific requirements. Customizing the tool set reduces downtime and optimizes performance.

Analyze the extent of the project to choose on attachments. Different projects might call for different answers. Customizing with flexibility guarantees your mini excavator meets the need.

Always check with professionals or rental companies. Their direction will help to choose the appropriate instruments. Appropriate customizing improves project results and output of productivity.

Renting vs. Owning: Mini Excavators

Renting mini excavators has clear benefits over buying them. Purchasing equipment straight-forward may not be possible for many companies, particularly smaller ones. Renting offers another that keeps freedom.

Renting might be more sustainable financially as well. It lets companies distribute money to other important areas without making a significant initial cost. Moreover, rental costs are predictable, which helps to create budgets.

Renting also helps with maintenance, another issue avoided. Usually, rental firms handle all maintenance chores. This helps to maintain seamless operations by reducing concern about repairs and service.

Renting also allows one to access the newest models. This guarantees the use of features and modern technologies, therefore improving efficiency. It helps businesses stay competitive without always spending on equipment improvements.

Seasonal or temporary project requirements fit renting rather well. Equipment is not needed kept or stored during downtime. For changing project needs, renting appeals because of this adaptability.

Besides, renting periods are flexible. Companies may pick times ranging from days to months that fit certain project plans. This flexibility meets demands unique to a project without long-term commitment issues.

Why Renting Is the Wise Decision

Renting gives equipment right away access. There is no waiting period, allowing rapid project commencement. This effectiveness guarantees meeting of strict deadlines.

One of the main reasons to rent is economy. It releases the weight of big initial money. Rather, companies may direct resources to meet operational requirements.

One further advantage is risk reducing. One machine is not committed to anything long term. Businesses may change models to fit different project needs free from budgetary constraint.

Renting gives businesses changing their emphasis or increasing flexibility. It fits well with corporate changes. Making sure that obsolete or extra equipment doesn’t stop operations.

Choosing the Correct Mini Excavator Rental

Start by looking at job criteria. To get the excavator size, list the jobs and scale. For best performance, match the features of the model with project requirements.

Investigate renting businesses carefully. Seek for respectable companies with good client comments. The dependability of a corporation usually reflects its level of services.

Ask about more services and assistance. Good rental agreements provide insurance, help, and maintenance. These may help initiatives to provide peace of mind.

At last, carefully consider the conditions of contracts while analyzing the insights mini excavators market. Make sure use and price fit project requirements. Knowing the details guarantees a good rental experience and helps to avoid unexpected expenses.

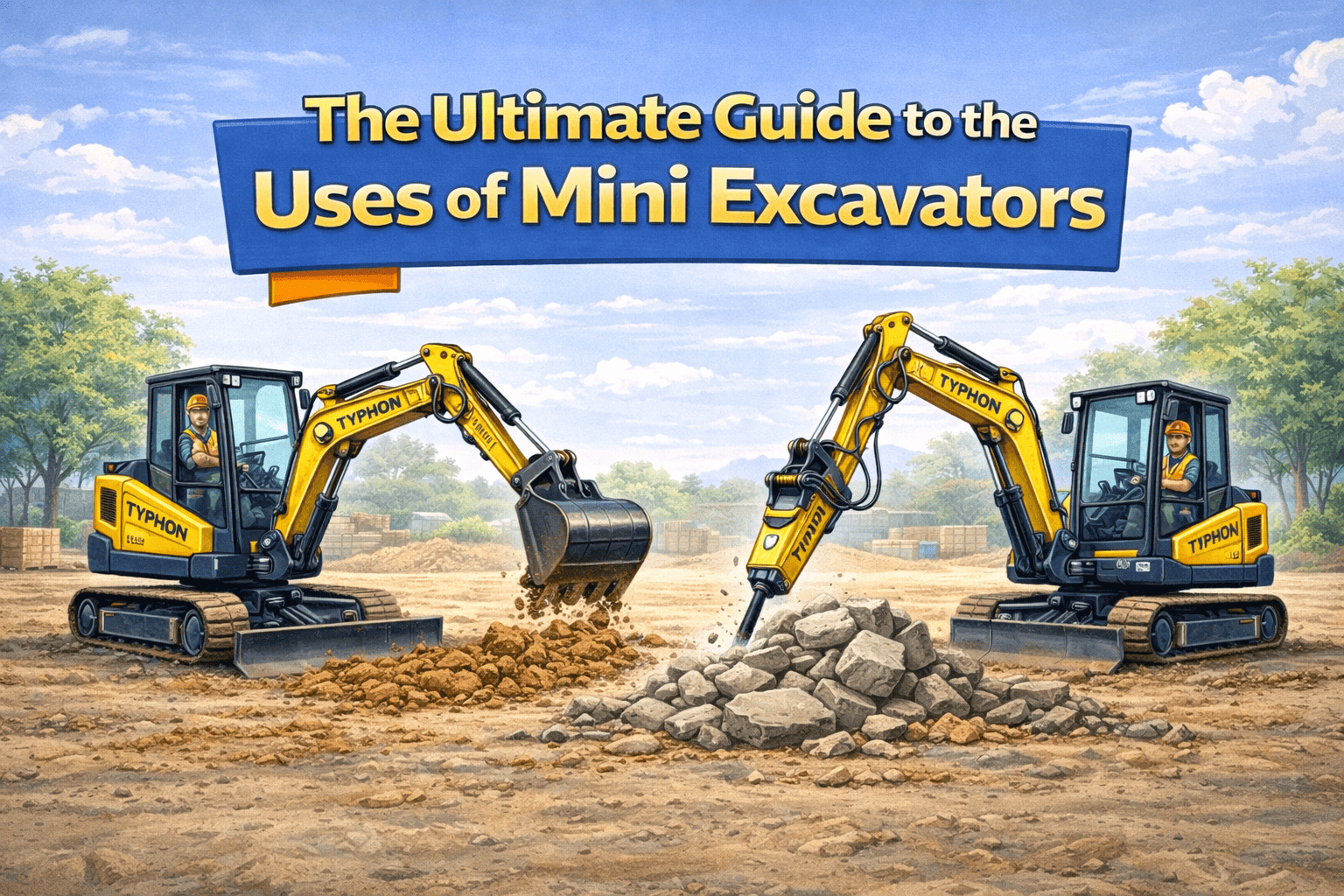

Large Jobs, Small Package: Mini Excavators in Use

Mini excavators have shockingly great power. They can manage jobs usually assigned to bigger machines. Unmatched in adaptability, they are very essential on many different project locations.

These little tools can fit into limited areas. For procedures needing accuracy and flexibility, they are perfect. Once difficult tasks because of size restrictions are now possible.

Mini excavators do a variety of tasks depending on the attachments. They easily excavate, lift, and destroy. Their flexibility qualifies them for many different sectors.

The smaller footprint disturbs the earth very little. Projects requiring care around existing buildings or fragile settings would be ideal for this soft approach. Mini excavators protect delicate places of integrity.

Projects in Residential and Landscape Design

Mini excavators really shine in homes. They help with jobs like utility trench digging. The devices can easily grade dirt for use in landscaping projects.

Their accuracy is great for putting in things like backyard ponds. Minimal disturbance preserves the property of the homeowners. Mini excavators provide clean, quick completion of jobs.

They shine in limited areas and close yards. Their small scale makes access possible where bigger machinery cannot walk. Mini excavators do home tasks without any problems.

Applications in Urban and Municipal Areas

Mini excavators really help urban areas. They do basic jobs like trenching for new pipelines. Their tiny scale reduces interference on busy metropolitan streets.

Mini excavators are very useful in municipal maintenance work. Jobs like sidewalk maintenance and park beautification streamline themselves. Their use guarantees effectiveness in preserving infrastructure and city looks.

Lower noise levels fit cities with noise sensitivity. Mini excavators run without disturbing the serenity in homes. Early morning or late-night municipal work would be ideal for this capability. The global mini excavator market has larger impact and small, medium and large projects.

Industries and Specialized Tasks

In specialized fields, mini excavators shine. With accuracy, they manage delicate archaeological excavation so as to preserve history. Their small size provides flexibility in visiting challenging locations.

Still another specialization is utility installation. Mini excavators gently lay pipes and wires. Industries with speciality value their accuracy and capacity.

Their adaptability helps forestry chores. Mini excavators support site preparation and underbrush clearance. They are vital in many different fields as they efficiently meet special industrial problems.

Running mini excavators: safety and ease of use

Running a mini-excavator is simple. The controls are user-friendly and easy. Even beginners can pick things fast, therefore cutting the need for instruction.

Modern safety measures abound on these devices. These cover alarm systems and rollover protection systems. Such characteristics improve operator safety, a vital consideration on any building site.

Reduced noise helps them to be more comfortable. Reduced tiredness by operators guarantees effective and safer operation. The cabin’s careful layout improves view even further.

Usually done by operators themselves, regular maintenance is easy. This simplicity reduces project downtime. Simple maintenance maintains efficient functioning.

Both project managers and operators choose mini excavators mainly because they combine modern safety with simplicity.

Learning Mini Excavator Operating Techniques

It is really easy to master a mini excavator. Simple controls are provided by most models. Usually within hours, operators are very competent on mini excavator how to handle them properly.

There are plenty of training materials out there. Many rental businesses provide seminars. These help operators to enhance their work performance.

A short learning curve promotes more general acceptance. Those who like do-it-yourself projects find running these devices less frightening. This inclusiveness gives consumers from all backgrounds empowerment.

Safety Elements and Optimal Strategies

Mini excavators’ safety is first concern. Systems of rollover protection provide one piece of mind. This capability reduces running hazards.

One of best practices is doing pre-operation inspections. Frequent maintenance extends the life of the machinery. It guarantees also efficient and safe operation of the equipment.

Operators should be alert. Knowledge of the environment helps to lower incidences. This approach guarantees strong project performance along with safety aspects.

In general, the future is compact.

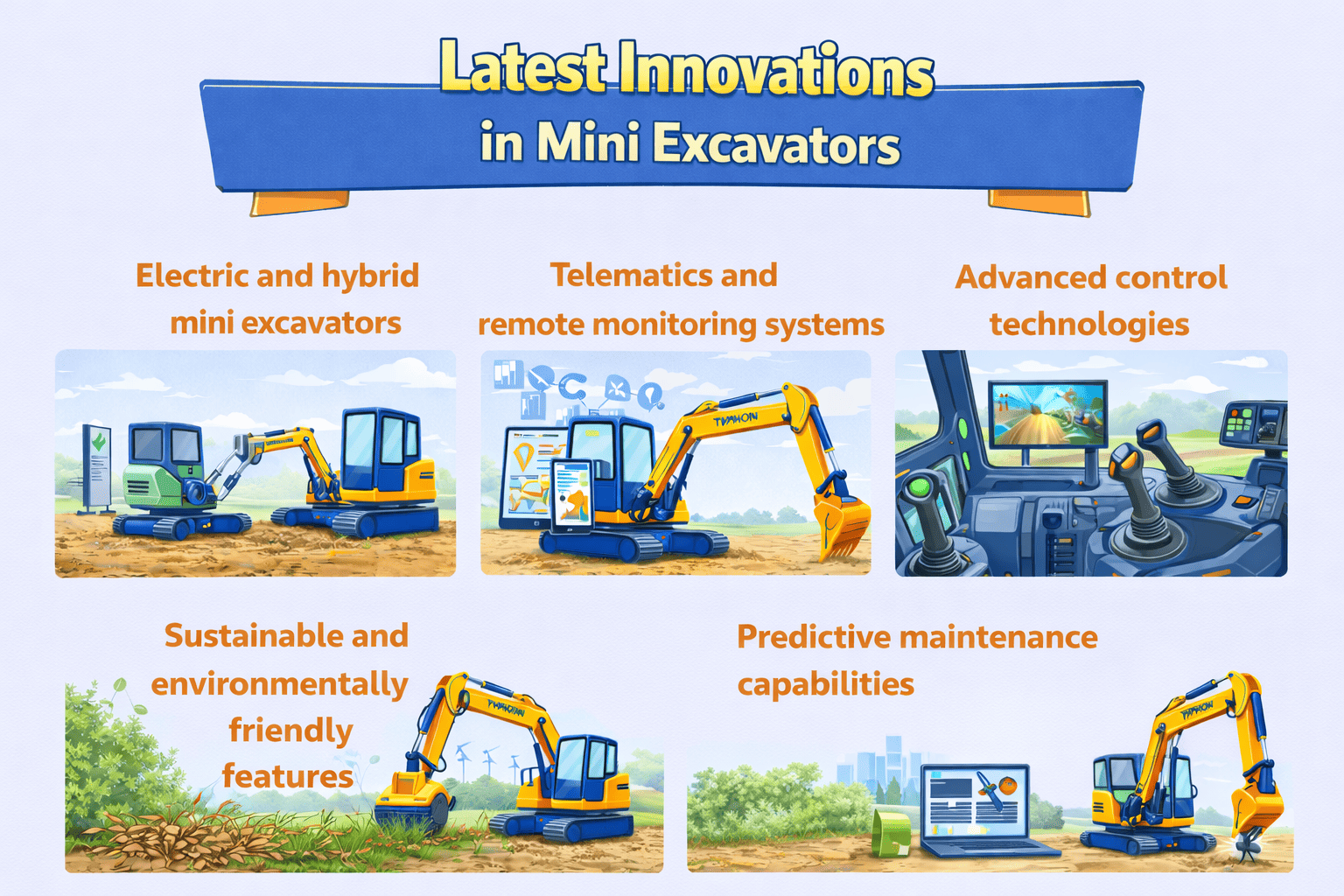

Mini excavators are changing the scene of building. Their adaptability and small scale make them very essential for many kinds of tasks. Their uses would only grow as technology develops.

Demand for these clever devices is rising. Smaller, more flexible equipment will surely rule the market in a future. Mini excavators have a very significant effect indeed.