10 Essential Attachments for Mini Excavators: Mini excavators are flexible. Their skills include excavating, grading, demolition, and debris disposal. Their true strength is adaptability. Mini excavator attachments excel here.

Mini excavators may be flexible with attachments. They may enhance its functionality, making it suitable for many tasks.

From buckets and hydraulic hammers to augers and grapples, the options are vast. Every attachment is designed to improve certain jobs.

Mini excavator efficiency may be improved by choosing the right attachments. It may also extend its lifespan, increasing your ROI.

This post covers the top 10 mini excavator attachments. It helps you find their uses and benefits.

Explore Mini Excavator Attachments

Attachments on a mini-excavator are crucial. They considerably boost machine flexibility. Attachments let excavators do tasks beyond just digging. Every interaction has a purpose as one needs to excavate, smooth, disassemble, and regulate materials. The right decision could raise workplace efficiency and output.

Before choosing an attachment for mini excavators, consider the job needs and capacity of the excavator. Your little excavator model will run properly only if you have the correct components. Wise decisions improve excavator efficiency and safety.

Buckets: Adaptability’s Soul

Mini excavator attachments need buckets. These devices are defined by their function. You may easily do several things with a bucket.

Different containers serve different purposes. A sturdy digging bucket is needed for excavation. Wider grading buckets are great for smooth finishes.

Attachment trenching bucket for mini excavators also helps to make perfect trenches on the field. Each kind is built for certain duties, assuring efficiency. With them, operators may easily manage many projects.

Some common buckets are:

- Digging buckets: Ideal for turning soil.

- Grading buckets: Perfect for leveling surfaces.

- Trenching Buckets: For narrow trenches.

Choosing the right bucket boosts mini excavator efficiency. Consider the topic and task needs before choosing. This ensures lifespan and productivity.

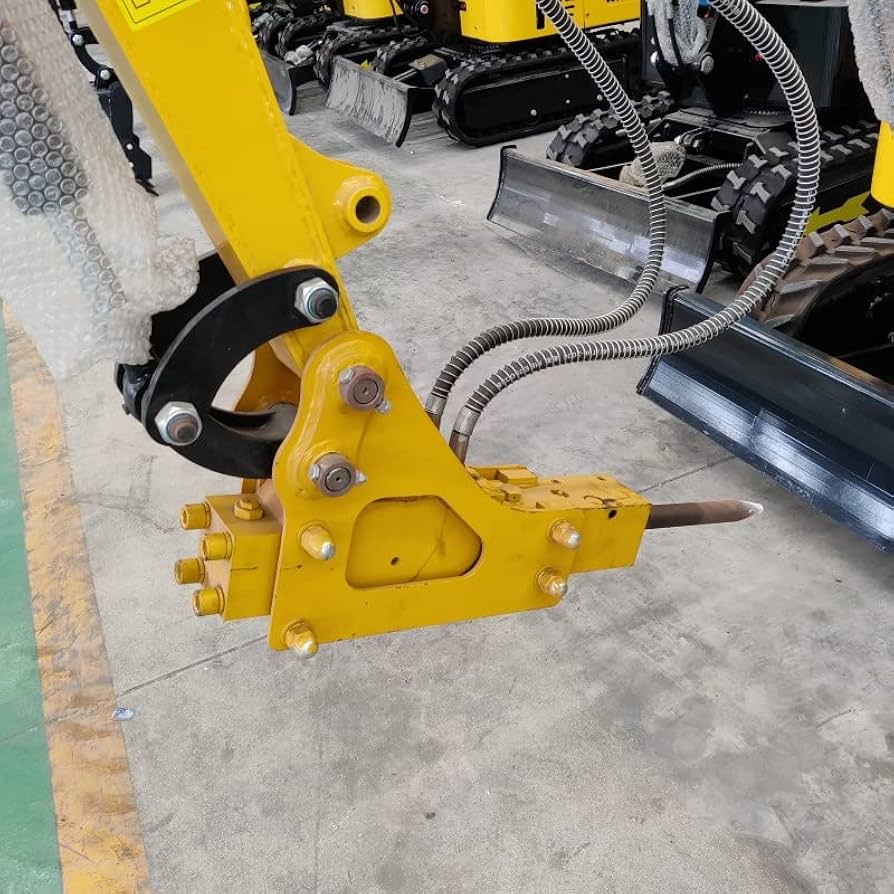

Hydraulic Hammers: Innovations

Hydraulic hammers make small excavators powerful demolition equipment. They are vital to penetrating tough material. Contractors working with concrete or rough terrain need this accessory.

The hydraulic hammer strikes quickly and hard. These impacts are essential for dismantling heavy items. It’s best for demolishing structures.

Different excavator types may use hydraulic hammers of varied sizes. Compact hammers suit cities. Bigger ones tackle heavy duties easily.

Essential hydraulic hammer duties include:

- Remove concrete slabs and foundations.

- Rock Breaking: Divide large stones.

- Asphalt removal: Road and walkway cleanup.

Hydraulic hammers must be chosen carefully. Consider hydraulic excavator pressure and flow. Optimizes attachment performance and durability. Safety is key with hydraulic hammers. Protective gear and training are necessary. Protects operators and enhances productivity.

Carefully Drilling Using Augers

Augers are crucial for precise hole-making. Outdoor locations and construction projects benefit most from them. Fast, efficient drilling saves time and effort.

These instruments vary in width to suit different uses. Every project, from deep foundations to post-holes, calls for an auger. The specifications of the project should guide auger size.

Mini excavators’ hydraulics power augers. This guarantees dependable functioning in difficult soils among hydraulic thumb clip attachment. Make sure the machine’s hydraulic capacity matches the auger’s.

Augers’ typical uses include:

- Post hole digging plays Ideal role in fences and signage.

- Create perfect conditions for young plants with planting more trees.

- Stability requires foundation piling for a standard process.

Beyond size, choosing an auger needs thought. Consider soil type and obstacles. Clay, sand, and rock may need special auger tips or power.

Care for augers extends their lifespan. Regularly check for wear and tighten bolts and connections. This will prevent disturbances and stabilize drilling.

Grapples: Engaging Solution

Mini excavators become grasping equipment with grapples. They handle various materials well. Grapples easily lift logs, rocks, and building waste.

Grapples grip uneven items due to their design. They are great for carrying odd-shaped goods. Their versatility in debris control is unmatched.

Different grapples have different uses. These include root, log, and demolition grapples. Choose the right kind for the job.

Essential grapple uses include:

- Sorting waste: Helps organize construction detritus.

- Landscaping: Moves rocks and heavy lumber easily.

- Demolition: Safely removes major building sections.

Consider material size and weight while picking a grapple. Ensure the small excavator’s hydraulic system is compatible with its hp bs engine mini excavator. This ensures smooth operation and reduces equipment stress.

Grapples need regular maintenance to work well. Regularly inspect hydraulic connections for wear. The attachment will last longer and function better with proper maintenance.

Rating: Better Material Management

Mini excavators require thumbs. They increase grip on uneven materials. Increased expertise simplifies things. Thumb attachments add hands. Bucket assistance is increased. Thumbs make grasping and handling simple. Thumbs important in construction and gardening. They position stone, wood, and natural materials precisely. This improves worker safety and efficiency.

Common functions:

- Material management and transportation are made easier with loading and unloading.

- Helps remove fallen branches and debris.

- Landscaping: Arranges huge stones and plants.

Consider the excavator’s size and duties while picking a thumb. Fixed thumbs are sturdy and simple. Hydrolic thumbs are diverse and useful. You must align a thumb with the bucket before installation. Normal wear and hydraulic leak checks boost durability. This versatile item lasts longer with regular care.

Rippers: Navigating Difficult Settings

Rippers are crucial to ground preparation in difficult situations. Great at loosening hard or frozen terrain. Mini excavator attachments facilitate hard operations.

Mainly, rippers break through and soften rigid layers. They are ideal for deep excavations. Operators can easily break compacted ground using rippers.

and soften rigid layers. They are ideal for deep excavations. Operators can easily break compacted ground using rippers.

Rippers are used in agriculture, construction, and forests. They break up clay, rocky, and frozen soils. Their versatility makes them valuable in many sectors.

Rippers are used for:

- Narrow ditches may be dug quickly and easily.

- Land clearing is important for gently removing roots and boulders.

- Roadwork is a continuous process to removes old asphalt and prepares soil for rehabilitation.

Choosing a ripper depends on soil type and mini excavator strength. Heavy-duty rippers are best for severe chores, while lightweight ones are better for easier ones. Maintaining top performance and preventing unexpected failure requires regular checkups. Rippers may boost excavation efficiency with proper care.

Plate compactors boost efforts

Plate compactors stabilize loose materials. They’re great for ground stability. The attachments compress soil, gravel, and other materials severely. Vibrations power plate compactors. Increasing material density via vibrations reduces settling issues. Compaction stabilizes foundations during construction. These tools are for trenching, landscaping, and roadbuilding. They may compress hard-to-reach dirt. They skillfully prepare areas for paving or construction.

Plate compactors are used for:

- Trench compaction stabilizes backfill, decreasing settlement.

- Foundation Preparations establishes stability and prevents movement.

- Paving projects provide smooth, sturdy paths and roads.

Compatibility and weight are important when choosing a plate compactor. Attachment hydraulic capacity should match the excavator. Regular maintenance ensures smooth functioning. This prolongs the compactor’s and excavator’s life. Compaction improves project efficiency and quality. Plate compactors increase building results when utilized properly.

Tiltrotators—Full Circular Efficiency

Mini excavators benefit from tiltrotators. Their 360-degree spin gives them flexibility. This makes challenging angles easy for the attachment. Their adaptability appears in limited areas. Tiltrotators make obstacle navigation easy. They reduce time by minimizing machine adjustments. Many applications benefit from these compact excavator attachments. They increase trenching, digging, and grading accuracy. Better control boosts task accuracy.

Advantages of tiltrotators include:

- Improved Maneuverability helps to manage difficult areas easily.

- Reduced machine movement increases productivity.

- Job Precision improves accuracy.

Make sure a tiltrotator fits before buying. Small excavator rules should apply. They boost performance but need upkeep. Frequent inspections improve equipment performance and lifespan. Mini excavators benefit from difficult angles. Employee productivity and accuracy improve with tiltrotators.

Brush Cutters: Clearing Paths

Land management relies on brush cutters. They make your small excavator plant-removal-friendly. These accessories easily organize messy rooms.

Underbrush and weeds are easily removed with their design. They can handle deep grass and mini trees. This versatility helps landscapers and developers.

Brush cutters vary in size and design. Choosing the right solution depends on the plants and landscape. Consider how much energy your activities need.

Essential brush cutter features:

- Sharp Blades: Traces thin plant growth.

- Flexible: For many environments and plants.

- Time-saving: fast clearing of big areas.

Your mini excavator may not work with the brush cutter. Keep hydraulic flow balanced. Regular maintenance prevents damage and boosts performance. Using brush cutters boosts productivity. They have sturdy ground preparation and maintenance equipment for small excavators. The correct brush cutter helps people manage their environment or clear paths for projects. These attachments show plant growth management efficiency.

Pallet Forks: Improving Standards

Material handling is transformed by pallet forks. Mini excavators move and lift objects effortlessly. The adaptability is essential in hectic job locations. This attachment makes your excavator a forklift. Moving logs, pallets, and other big items is easy. Adaptability drives work efficiency.

Before selecting pallet forks, consider the lifting capacity of your compact excavator. Ensure your equipment aligns with the weight capacity and fork dimensions. This method provides a sense of balance and smooth functionality.

Pallet forks have several advantages:

- Suitable for variety of lifting tasks in various climatic fields.

- Reduces physical effort of a worker and speeds the working process.

- Efficiently reduces the site duration and personnel costs.

Standard forklifts struggle in narrow places, but pallet forks work well. Space-constrained building locations benefit from them. Their usage considerably reduces equipment needs.

Safety first while using pallet forks. Prepare operators to properly handle loads among excavator attachments mini and major projects. Regular inspections and maintenance keep the attachment in good condition. Pallet forks improve excavator capabilities and worksite efficiency.

Choose the Right Attachments for Mini Excavator

Choosing the right attachments improves your mini excavator’s performance. Evaluate your planned tasks. The attachment should match the task for optimal performance.

Consider its compatibility with your mini excavator. Verify size and capacity specs since not all attachments fit all models. This ensures safe and easy operation without straining the equipment.

Choose high-quality, long-lasting attachments. Premium products reduce wear, downtime, and extend excavator and attachment life. Find trustworthy companies and positive reviews to help you decide. Selecting the proper attachments boosts project and operator satisfaction.

Nurturing and Protection: Fostering Connection

Mini excavator attachments need regular maintenance to last. Start with regular inspections to notice wear and tear quickly. Fixing issues quickly may save money. Lubricating components reduces friction and extends life. Use the required grease or oil for each attachment. This small surgery improves durability and efficiency.

Maintenance and safety are crucial, therefore we should regard them equally. Taught operators safety and attachment handling. Handling mistakes may ruin tools. Proper storage maintains attachment quality and function while not in use.

Maximizing Mini Excavator Potential

Selecting the right accessories may make your mini excavator very flexible. Each attachment has distinct features that make it easy to handle diverse jobs. Choose sturdy attachments for digging, breaking, and lifting to improve efficiency.

Consider present and future initiatives while planning your small excavator’s future. Attachments may enhance productivity and ROI with careful selection. Careful selections and equipment maintenance may boost your small excavator’s performance.