A mini excavator that weighs 2 tons is a very useful and powerful tool for small construction, gardening, and farming tasks. Typhon Machinery’s engineering makes it the perfect mix of accuracy, strength that lasts, and good looks. This detailed review goes over the Typhon TYPHON TERROR XVIII Prestige 2 Ton Mini Excavator’s technical features and benefits, as well as its many uses and what buyers should keep in mind.

Overview: Compact Power Meets Efficiency

The 2 ton mini excavator is a tool meant for situations that require a limited working area but a high level of performance. TERROR XVIII Prestige by Typhon Machinery is a flagship model that basically sets the standards of what can be expected in this class. It is a perfect match for construction companies, landscapers, and real estate developers who are in need of a powerful machine in a small space, as it weighs about 2,000 kg, is powered by a Kubota D902 diesel engine, and is built for easy handling of the working area.

Highlights

- Weight of the machine: about 2 tons (4,400 lbs)

- The engine is a Kubota D902 diesel with three cylinders and water cooling.

- Output: 20.4 HP @ 3600 RPM

- The digging depth is around 2060 mm, and the bucket can hold 0.03 m³.

- Boom Swing: Yes, with a design that lets you change the offset.

- Optional heater/air conditioner cabin for the operator’s comfort

Engineering Excellence: Inside the Typhon TERROR XVIII

The TYPHON TERROR XVIII Prestige 2 Ton Mini Excavator is a great example of Typhon’s commitment to compact engineering performance, durability, and operator comfort.

Kubota Diesel Engine

The D902 engine from Kubota is very reliable and operates smoothly. The vertically oriented, water-cooled, 3-cylinder, 4-cycle engine delivers lower fuel consumption and less noise, making it ideal for residential and landscaping work.

Hydraulic System

Designed with very close to perfect hydraulics component, the 2 ton mini excavator is a machine that can be relied on for smooth digging, lifting, and loading. The free hydraulic thumb clip extends the effectiveness of material handling.

Operator Comfort

The Prestige model goes beyond comfort with an optional fully enclosed cab that can be both air-conditioned and heated, a feature that is hardly ever seen in the world of compact excavators. There are also easy-access controls, ergonomic seating, and broad visibility that provide the utmost safety and productivity.

Versatile Attachments

The 2 ton mini excavator can operate multiple tools such as:

- Standard digging bucket (380mm)

- Hydraulic thumb clip

- Auger and breaker attachments

- Tilting bucket (optional)With this versatility, the machine can be rapidly changed over for drilling, trenching, or grading work.

Efficiency and Performance

A 2 ton mini excavator bridges the gap between light-duty skid machinery and full-scale excavators. With a small footprint, it can deliver impressive breakout force and digging precision.

Compact Dimensions

Its short swing radius and extendable undercarriage make it maneuverable in backyards, narrow alleys, and urban job sites.

Fuel Efficiency

Thanks to the Kubota engine’s compression ratio and combustion efficiency, owners enjoy lower operating costs and minimal emissions—enabling both EPA and Tier 4 compliance.

Smooth Operation

Independent boom swing and responsive joysticks provide fine control even in delicate digging tasks such as irrigation trenching or root excavation.

Applications Across Industries

The 2 ton mini excavator is favored in industries requiring compact, agile, and economically operable equipment.

Construction and Civil Work

-

Small foundation excavation

-

Road maintenance and sidewalk repair

-

Utility line trenching and cable laying

Landscaping

-

Tree planting and stump removal

-

Lawn or garden shaping

-

Retaining wall installation

Agriculture

-

Ditching for irrigation

-

Land leveling for greenhouse setups

-

Cleaning small ponds or drainage canals

Demolition

-

Dismantling sheds or lightweight structures

-

Clearing site debris efficiently

Typhon Machinery Advantage

Typhon Machinery distinguishes itself through advanced design thinking and value-added features. The TYPHON TERROR XVIII offers high-grade hydraulics, luxury comfort, and strong build quality tailored to US and global metric standards.

Why Choose Typhon?

-

US-Based Support: Reliable parts and customer service network.

-

Premium Components: Kubota engines and durable pins (25 mm sized for heavy-duty endurance).

-

Complete Kit: Comes with bucket, toolbox, and operator manual out of the box.

-

High ROI: Low maintenance cost and top resale value for fleet owners.

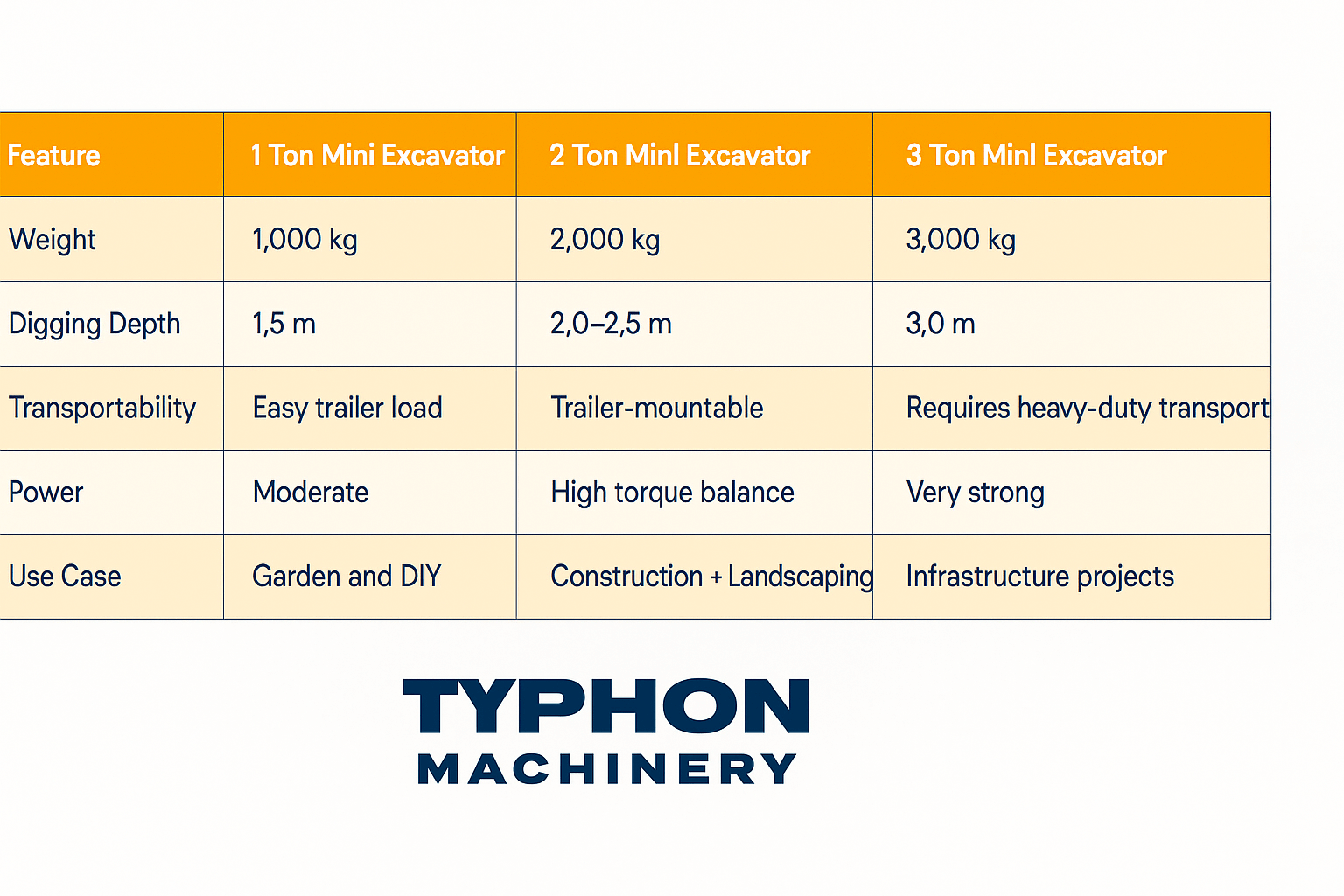

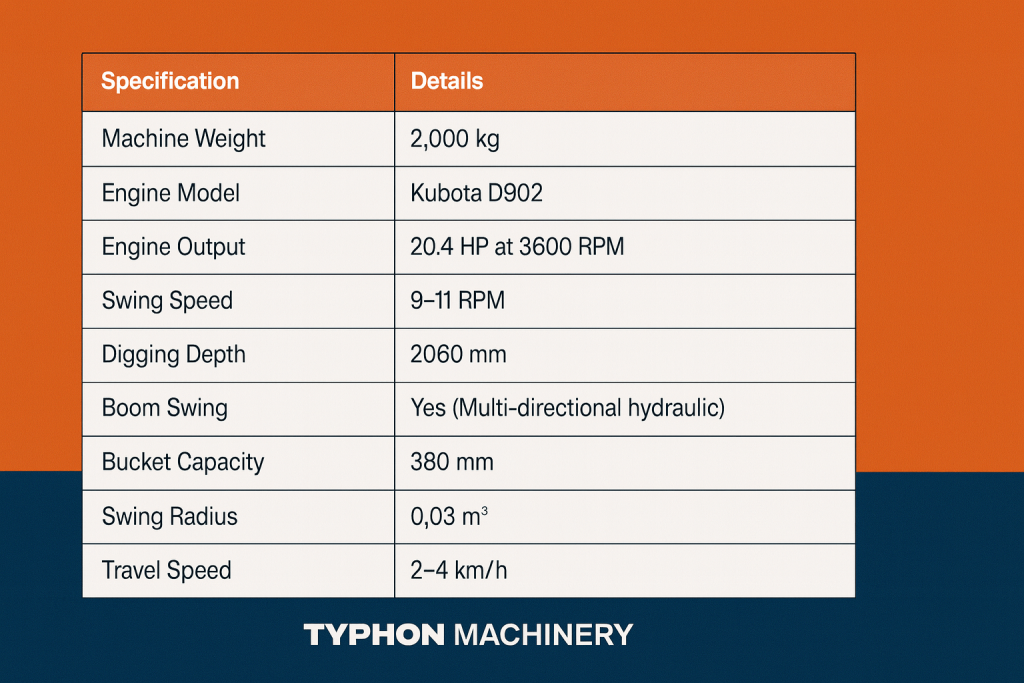

Technical Specifications (TYPHON TERROR XVIII)

Ease of Maintenance

Typhon machines are manufactured in such a way that they can be easily maintained over time. It is easy to search the hydraulics of the machine through access panels as well as the engine compartments, which are also designed for quick inspection and filter changes. In addition, with a simplified powertrain layout and readily available Kubota-compatible parts, the time which is not productive is kept to a minimum.

Safety and Stability

Despite its size, the 2-ton mini excavator maintains excellent stability through its low center of gravity and extendable track chassis. For enhanced safety:

-

ROPS-capable design for operator protection

-

Boom inspect valves for hydraulic pressure stability

-

Emergency shut-off systems near operator seat

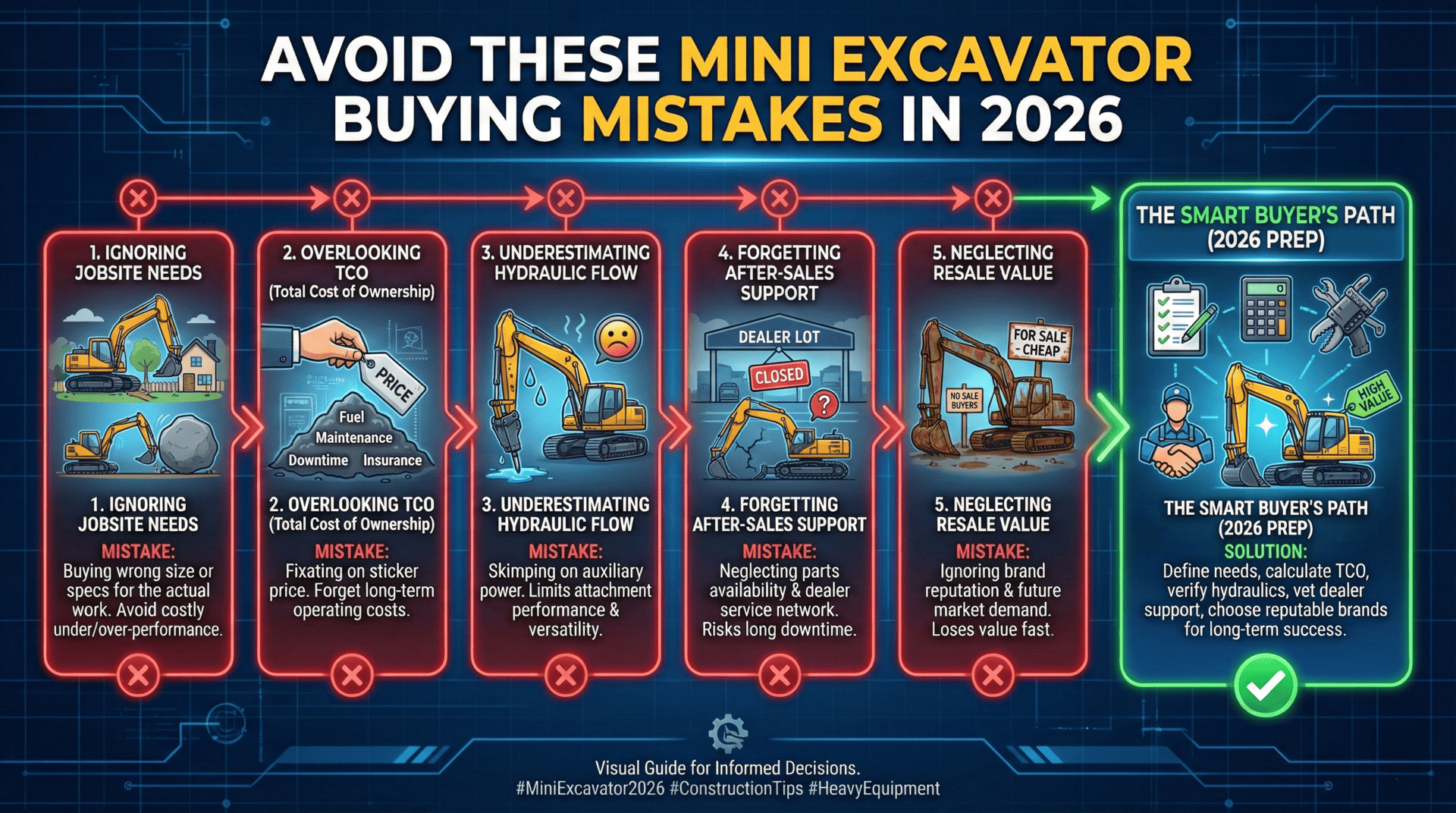

Cost, Value, and Ownership Benefits

Owning a 2-ton mini excavator from Typhon Machinery means enjoying a perfect balance of power, performance, and low ownership cost.

Fuel and Cost Efficiency

Consumes 30–40% less diesel than standard 3T excavators while maintaining strong digging forces.

ROI and Resale

Because of Typhon’s reliability reputation and Kubota engine longevity, resale value remains high—making this an intelligent fleet investment.

Available Extras

-

600 mm tilting bucket (included in selected packages)

-

Aftermarket auger drives and breakers

-

Custom paint and branding options for businesses.

Real-World Performance Cases

Contractors report that the 2 ton Typhon mini excavator performs well across terrain types—from urban backyards to muddy agricultural zones. The wider track footprint makes it suitable for uneven or soft soil without significant rutting.

Operators also appreciate its precision control while trenching electric lines or gas connections in restricted city plots.

The Future of Compact Excavation

Among small-scale earthmoving equipment that is changing, the 2 ton mini excavator remains the most versatile, agile, and cost-efficient solution. Typhon Machinery takes this class to the next level with the TERROR XVIII Prestige, a device that combines top-notch engineering and luxury features designed for the comfort of the operator.

Anywhere you can think of—the farm or the construction site, trench digging or demolition prep—this powerful yet small excavator is changing the way professionals handle small-scale excavation. It is not only a tool but also a sign of the performance, precision, and reliability of Typhon.

Write a features and specs section referencing Typhon Machinery

Features and Specifications—Typhon Machinery 2 Ton Mini Excavator

The TYPHON TERROR XVIII Prestige 2 Ton Mini Excavator by Typhon Machinery is a perfect example of how the brand aims to integrate power, accuracy, and user comfort in their compact construction machines. This mini excavator, which is a combination of Japanese-engineered reliability and American design optimization, is literally a powerhouse in its class.

Key Features

1. Compact and Powerful Design

Engineered for small and medium construction projects, the TERROR XVIII offers optimal mobility in tight workspaces while maintaining impressive breakout force and stability. Its compact build allows easy access into gardens, residential yards, and urban construction zones.

2. High-Performance Kubota Engine

Powered by a Kubota D902 diesel engine, this machine delivers 20.4 HP at 3600 RPM through a 3-cylinder, 4-cycle, water-cooled IDI engine known for durability and fuel efficiency. This setup ensures reliable operation under continuous heavy-duty use.

3. Diverse Application Range

Ideal for digging, drilling, bulldozing, ditch cleaning, trenching, landscaping, and rock-breaking, the 2-ton mini excavator adapts to multiple work environments—parks, farms, roads, and construction sites.

4. Boom Swing and Hydraulic Control

The versatile boom swing system increases flexibility in trenching and close-wall digging operations. Its precision-tuned hydraulic system allows smooth, responsive operation and greater control for first-time users.

5. Ergonomic Operator Cabin

The Prestige Edition includes a luxurious cabin with integrated air conditioning and heating—rare in compact models. The cabin also features ergonomic levers, an intuitive control panel, and large visibility zones to reduce operator fatigue during long shifts.

6. Safety and Durability

Manufactured with reinforced booms, 25 mm high-tensile joint pins, and a low center of gravity, the TERROR XVIII ensures enhanced stability. Every unit complies with EPA certification standards, confirming both safety and low emissions.

7. Comprehensive Excavation Package

Each mini excavator comes fully equipped with:

-

1 × 0.03 m³ standard digging bucket (380 mm)

-

1 × Toolbox and digital manual

-

1 × Cabin or canopy (air conditioner/heater option for Prestige)

- 1 × Free hydraulic thumb clip attachment

This complete kit ensures buyers are ready for operation right out of the crate.

8. Fuel and Hydraulic Systems

Equipped with a 6L fuel tank and 17L hydraulic oil tank, the system delivers continuous operation for extended tasks. Its advanced filtration system minimizes contamination and extends hydraulic life.

Technical Specifications—TYPHON TERROR XVIII

Why Typhon Machinery Leads in Compact Excavation

Typhon Machinery has engineered the TERROR XVIII to meet professional standards without sacrificing user simplicity. The combination of premium Kubota diesel technology, luxury-driven comfort, and heavy-duty architecture makes this 2 ton excavator an exceptional choice for contractors, farmers, and excavation specialists alike.

Each component—from the hydraulic joystick controls to the steel boom architecture—is crafted to deliver long-term resilience, consistent performance, and operator satisfaction, redefining what compact excavation can achieve in everyday worksites.

How does Typhon Machinery ensure mini excavator durability

Typhon Equipment keeps mini excavators in top condition through the combined use of durable material selections, clever designs, and state-of-the-art protective features. Every mini were constructed by Typhon excavators are made of high-strength steel and stainless steel frames are designed to resist harsh operations and wear; thus, the life of the most important structural parts is extended.

Typhon does not hesitate to integrate cutting-edge technology into its machinery, such as smart control systems, dual pump hydraulic setups for efficient oil flow, and an upgraded cooling system that permits the machine to be used continuously without overheating—even if it is a full-day task.

The protection of the hydraulic hoses through the routing and the strong joint pins that support the minimization of breakdowns and mechanical stress, and the use of stainless steel and heat-resistant parts for the areas that are heavily used and are exposed to heat are some of the ways the company has enhanced the durability besides that.

Besides that, the company’s commitment to durability is also evident in its maintenance-friendly design, which features easily accessible service panels and diagnostic telematics.

Predictive maintenance capabilities and real-time performance monitoring provide operators with a tool that helps them spot the problems that will become failures if not addressed, and thus they can act accordingly, reducing the downtime that is not planned and extending the lifespan of the machine. Typhon’s focus on durability translates into lower operating costs over the machine’s lifetime and a higher return on investment for owners.

What engine options are available for Typhon mini excavators

Typhon Machinery has a wide variety of engine options for its mini excavators, giving buyers the possibility to choose powertrains that are the most efficient for their particular use and available funds.

The best-selling engine of the mini-excavator series is the EPA-certified Kubota D902 diesel engine, which is installed on such models as the TERROR XVIII and TERROR XX and which delivers 20.4 HP, quietness of the operation, and the record of durability in the industry as a whole for the performance of small excavation tasks.

Moreover, some mini-excavator models from Typhon are going to be powered by the Kubota D1105 engine (with 25.1 HP) to provide more torque and bigger buckets, the Kubota V1505 engine (rated at 24.4–24.8 HP) for medium-weight machines, and Perkins diesel engines to those who want a reliable and easy-to-maintain 2.5-ton class.

Small units like the TERROR XIII or XV STORM may be equipped with gasoline engines such as Briggs & Stratton (B&S XR2100, 13–13.5 HP) and Honda (up to 22.1 HP).

Such a range ensures that the Typhon line is capable of fulfilling the needs of different users, be it heavy-duty trenching and landscaping projects or light construction and farm tasks.

What are the key differences in engine maintenance for Kubota vs Perkins

The primary distinctions between the maintenance of a Kubota and a Perkins diesel engine, which are usually found in mini-excavators, revolve around the differences in their maintenance intervals, designs of the systems, and the intricacy of the service:

Maintenance Intervals

- Kubota engines normally call for oil and filter exchange after the first 50 hours of work and then every 200-300 hours depending on the model and the conditions of work. Checking oil, coolant, and air filters should be done daily and is a must for ensuring good performance. Kubota prolongs the engine life through more frequent maintenance at shorter intervals.

- Perkins engines mainly have longer intervals between major services, for instance, 500 hours for oil changes and other main maintenance tasks. Perkins advises following a complete maintenance schedule that includes checks of coolant and valve clearance at longer intervals than those of Kubota.

System Design and Accessibility

- Kubota engines are thoughtfully designed for convenient access; they have fully opening bonnets and places for filters that are easy to get to thus simplifying routine maintenance out in the field. The small water-cooled system and fuel filters are very accessible; therefore, the servicing can be done quickly.

- Perkins engines, although they are also compact, may have more integrated systems that require skilled technicians for operations such as valve clearance adjustments and injector servicing. Usually, specific tools are needed for some Perkins engine adjustments and the fuel system maintenance might be slightly more complex.

Parts and Support

- Kubota offers worldwide parts accessibility and very easy-to-use service manuals, which in turn makes life a lot easier both for operators and service teams when they are looking for the parts that are necessary to perform regular upkeep and also for the parts which are needed to be changed. This is supported by a worldwide presence, which ensures expertise is always available.

- Perkins provides the same broad service networks, but sometimes it takes a while until the dealers have specialized parts, for example, injectors or advanced fuel system components, ready for you, and this is what leads to an increase in service complexity.

Fuel and Oil Specifications

- normally have specific oil and very high-quality fuel requirements in order to meet emission standards and to be able to work reliably at high revolutions per minute. At the same time, the fuel system maintenance is always focused on the use of pure fuel and quick replacement of the filter

- The engines are designed to be fuel flexible and may accept a broader range of diesel qualities, still the cleanliness of the fuel system should be the most important thing. Changes of oil along with filtration done in the Perkins engines focus on the protection of injectors and turbochargers.

Summary

Choosing between Kubota and Perkins engines depends on operator needs for maintenance frequency, local servicing capabilities, and project demands for engine robustness and flexibility.