7 Types of Excavators and Their Uses on the Construction Site: When you have to move large volumes of earth, your job site really needs an excavator. Popular earthmoving machines called excavators have a bucket, arm, spinning cab, and moveable tracks. These parts provide this large equipment greater digging power and mobility, thereby enabling it to carry out many tasks, from digging trenches and breaking holes to carrying away garbage and mining excavation.

- Crawler Excavators

- Wheeled Excavators

- Dragline Excavators

- Suction Excavators

- Skid Steer Excavators

- Long Reach Excavators

- Mini Excavators

What are excavators used for? Excavators are used for many different contractor and industrial purposes like mining, road building, building construction and demolitions.

Excavators come in several varieties; larger ones contain various equipment for heavy-duty tasks while smaller ones manage drilling and excavating. When hiring your excavator, you’ll want to think about its size and speed as well as working circumstances on the project site, including the quantity of space and the soil kinds.

Crawler, dragline, suction, skid steer and long reach excavators are the most prevalent kinds of excavators with features ideal for overview of the excavator. We will discuss every kind of excavator and the task each one is most suited for.

1. Crawler Excavators

Unlike other big excavators that operate on wheels, crawlers move on two enormous, unending tracks and are ideal for mining and heavy-duty construction work. Often referred to as compact excavators, these machines employ hydraulic power systems to raise dirt and heavy waste.

Their chain wheel mechanism lets them glide down and scale slopes with less risk, making them appropriate for grading mountainous regions and landscaping uneven terrain. Crawlers offer more balance, flexibility, and stability overall even if they are slower than conventional excavators.

Advantages: Offer more stability and balance over rough terrain

Drawbacks: Not as quick as certain other excavators

2. Wheeled Excavators

Similar in size and look to crawlers, wheeled excavators operate on wheels rather than tracks. While still providing the same power capacity, replacing tracks with wheels makes them quicker and more convenient to move over concrete, asphalt and other flat surfaces.

Wheeled excavators are often employed for roadwork and urban projects as wheels provide less stability on uneven ground than tracks. Operators, on the other hand, can install outriggers to improve stability during transition from an uneven terrain to asphalt or concrete.

Advantages: Quick and simple to navigate on level surfaces

Disadvantages: Bad performance on uneven ground

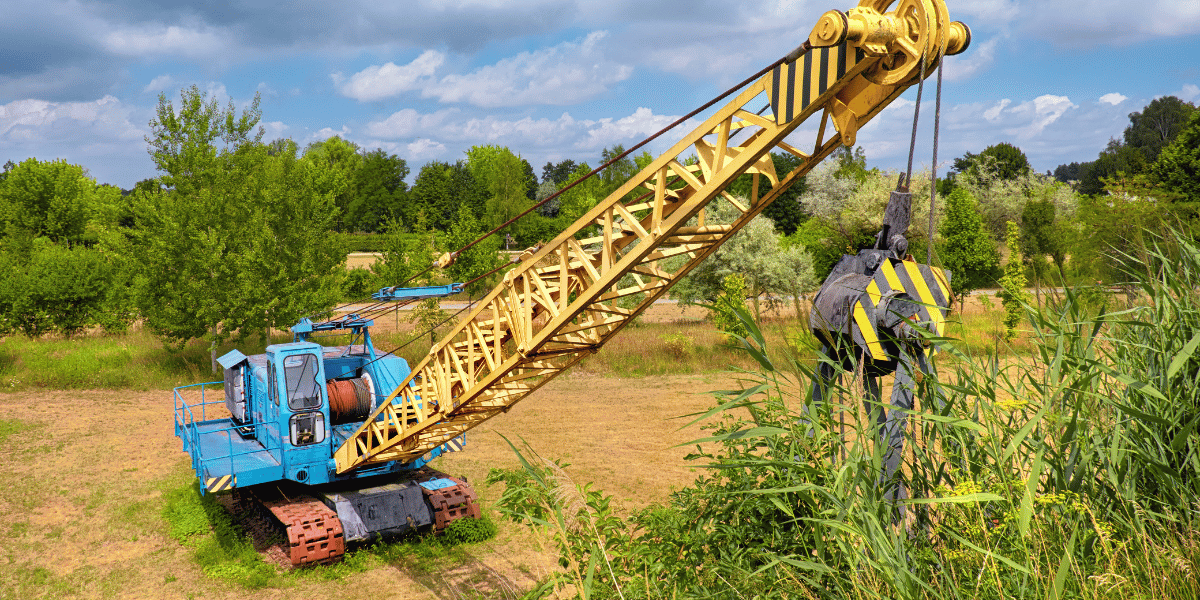

3. Dragline Excavators

Operating on a different method, the dragline excavator is a bigger excavator. The machine uses a hoist coupler to connect a bucket to a hoist rope system. A dragline running from the bucket to the cab holds the other side of the bucket. While the dragline drags the bucket toward the driver, the hoist rope lifts and lowers the bucket.

Draglines are sometimes built on-site because of their weight. Large-scale civil engineering projects like canal construction often employ the unusual mechanism of this kind of excavator.

Advantages: Canal dredging and underwater excavation are best served by dragline method.

Drawbacks: Size and weight render it unworkable for lesser tasks

4. Suction Excavators

Suction excavators, often called vacuum excavators, have a suction pipe that may provide up to 400 horsepower. To loosen the ground, the excavator first unleashes a water jet.

Then the pipe, which has sharp teeth at the edge, generates a suction removing dirt and debris up to 200 miles per hour.

For sensitive subterranean projects, a suction excavator is perfect as it may lower the risk of damage by more than 50 percent.

Advantages: Increased accuracy lowers harm during sensitive tasks

Drawbacks: For large-scale uses, small suction pipes are unpractical.

5. Skid Steer Excavators

Unlike standard excavators, skid steers have booms and buckets facing away from the operator. This configuration lets the attachments go over the cab rather than around it, therefore enabling these excavators to be usable in more restricted spaces and to negotiate challenging maneuvers.

Often used for digging pools, site cleaning, domestic maintenance, and rubbish clearance where space is more constrained and items are spaced widely apart.

Advantages: Simple to navigate in small and restricted areas

Drawbacks: On uneven or slick surfaces, they don’t function as well.

6. Long Reach Excavators

The long reach excavators, as its name implies, has a lengthier arm and boom components. The design enables improved functioning in difficult-to-reach areas. Over 100 feet horizontally, the extending arm of the excavator can reach.

Best employed for demolition tasks like structure cracking and wall breakdown over bodies of water, these excavators include The arm may accommodate many attachments to carry out further tasks including shearing, crushing and cutting.

Advantages: For demolition operations and hard-to-reach places, longer boom is perfect.

Drawbacks: Not suitable for small areas

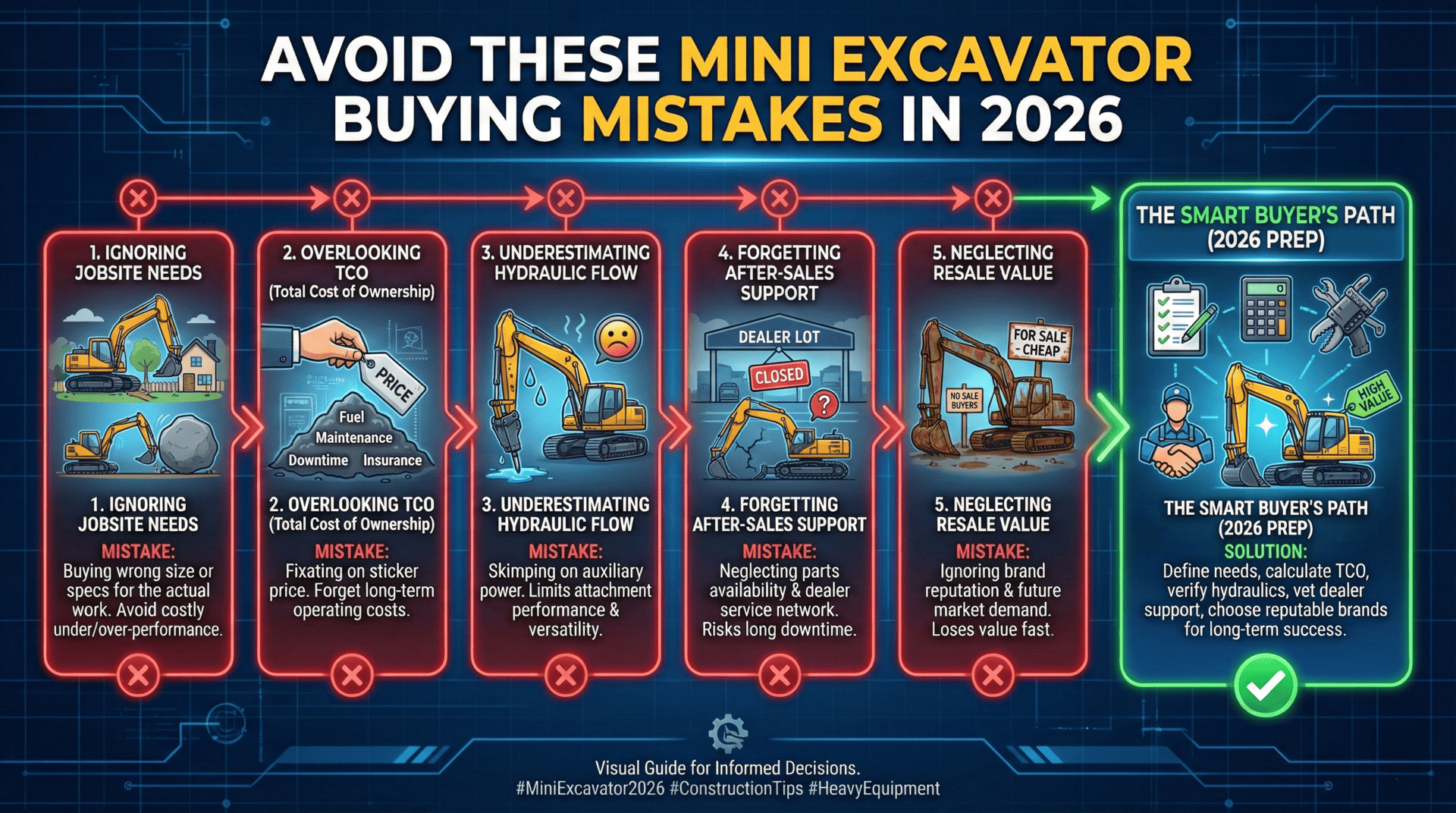

7. Mini Excavators

More contractors have been adopting mini excavators—smaller, lighter versions of the conventional excavator able to minimize ground damage and fit through congested, restricted locations like parking lots and inside areas—in recent years. Often referred to as compact excavators, micro excavators usually include zero tail-swing or lowered tail-swing to negotiate tighter corners and prevent obstacle contact.

Advantages: Easily fits into small locations and may be used indoors.

Disadvantages: Can only manage lesser loads

Excavator Attachments and Parts

The design of an excavator lets it fulfill several flexible functions. While a house-like cab gives the operator controls to guide the excavator, hydraulic cylinders, booms, arms and attachments offer digging and holding capabilities. To raise and remove trash from the workplace, a rotating platform and wheels give the required movement.

Excavators employ several hydraulic attachments with various functions. Apart from a bucket, additional frequent attachments are fast coupler, clamp, breaker, and auger.

Bucket

The most usual attachments shown on excavators are buckets. These steel attachments feature tooth-like edges that can offer scooping and digging capacity. The most frequent are ditching buckets meant for grading stones and trenching buckets used to excavate trenches, however buckets exist in many other kinds.

Auger

Attaching an auger lets you drill into the earth. These helical attachments, driven by hydraulic circuits, may drill deep holes and reach over anything. Ranging from 4 inches to 50 inches in length, augers come in varied specifications and sizes for different digging circumstances and terrains; they can dig up to 32 feet.

Breaker

Though far bigger in size, breakers are comparable to jackhammers. These attachments can penetrate more difficult materials including stone and concrete with up to 1,000 pounds of impact force.

Clamp

Clamps let excavator operators lift big items too heavy for a bucket, such tree trunks and concrete. The attachments may either be utilized with buckets or serve as components of a grapple. Clamps are simple to add and remove from excavators.

Coupler

Without a crew, couplers let you rapidly change between equipment and accessories. Their adaptability is useful while switching between various jobs and procedures on a work site.

Differences Between an Excavator and a Digger

Commonly seen on building sites, backhoes—also called diggers—are sometimes mistaken for excavators. Although they have comparable digging and lifting capacity, backhoes and excavators vary in size, weight, and use cost best uses of excavator.

Usually big machines, excavators may weigh as much as 200,000 pounds with excavator size cost best in the industry. Their bucket and boom design lets them spin a whole 360 degrees.

Conversely, a backhoe is usually far smaller and more closely resembles a tractor in look. The design allows just 200 degree side-to-side rotation for a backhoe. Its front and back buckets may push garbage toward the car, load rubbish, and unearth stuff. For light to medium-duty tasks with varied uses, renting a backhoe is ideal.

Although many various kinds of excavators exist, their fundamental uses are same along with size cost best uses for every excavator. Their lifting and excavating capabilities make them a mainstay on practically every building job. For many businesses, renting is the most affordable choice given their great expense.