Why Mini Excavator Should be Equipped with a Thumb Attachment

A new wave of zeal has engulfed mini excavators owing to their remarkable nimbleness, adaptability, and the fact that they are able to do wonders even in the smallest available spaces.

Nevertheless, even such a versatile machine has a limit, and for an excavator to be without a thumb attachment, its potential is very limited. A thumb attachment can be rightly referred to as a jack-of-all-trades for a mini excavator, as it greatly improves the productivity, precision, and safety of the equipment.

In this post, why and how the attachment works are discussed, as well as which of the devices one will select and how to make the right decision.

What Is a Thumb Attachment?

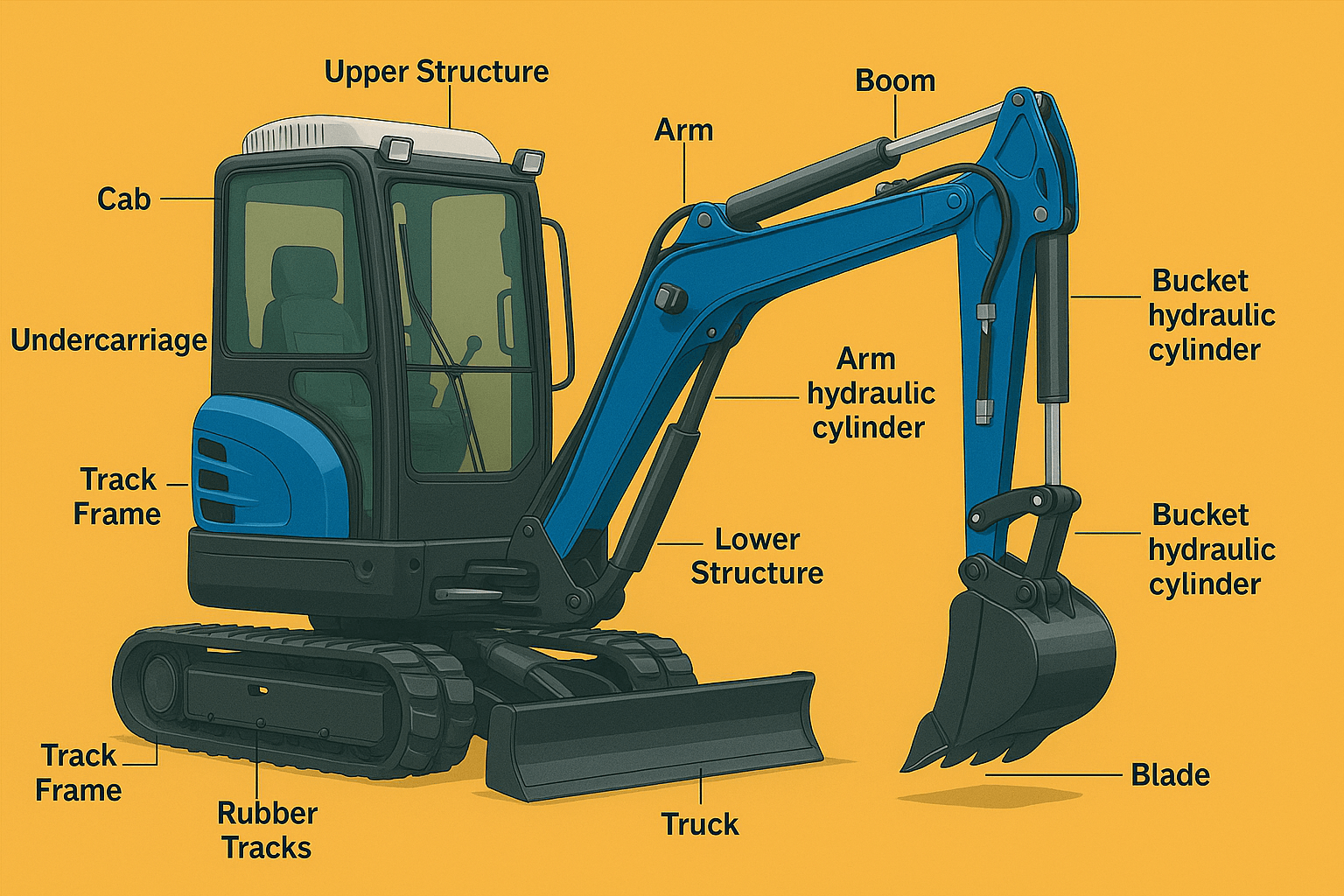

In essence, a thumb attachment is like another thumb to the machine, and it at the same time resembles human opposable thumb – it not only grabs items like human hands but is also what an excavator is using to hold the arm-end bucket.

These shared the same working principle that the thumb induces the bucket’s movements, providing the necessary force while the latter supports and practically functions as the host of the former. Here you can find the original post, Find the original web page here.

Visualize this equivalence: a hand in the form of a bucket and an open grip while adding a thumb makes the former a pincer that is capable of taking control and thus able to grip, lift, and lay with the accuracy of the latter. In an expanded sense, the drivers’ chores are not limited to just digging; they have a more sophisticated capability of materials management. 2. Thumb Attachment is Used for Top Purposes

The Main Good Sides of the Usage of a Thumb

Enhanced Versatility & Precision

More flexibility in material handling: Carrying timber, stones, pipes, or hazardous materials for the recovery process is made simple, secure, and quick.

Thumbs are an aid to multi-frictional applications: they can be used for landscaping and utility work, as well as for breaking down and recycling.

Accurate positioning control: The hydraulic thumbs cause the operators to be able to hold and control the items tightly and place them precisely between the stones in retaining wall construction.

Boost Motor Power

Improved velocity: The loading of mixed materials becomes a single-operation task, reducing the time needed to two-thirds by hand labor.

One way of expressing an operator’s efficiency: The breaking-down of a crew into a single person while work is still carried out is realized through the use of a thumb and a bucket.

Safety and Stability

Sure operation: It minimizes the risk of a load dropping or shifting, and thus the person who is introducing the load together with those on the sidelines remains in a safe position.

Unmovable weight: Beyond everything else, the thumb is especially helpful if lifting the weight that is of irregular shape.

Machine Value and Resale

Business and the Lifespan of the Machine and Its Values:

Higher selling prices: The buyers pay more for the excavators that come with thumbs—the market condition is such that the buyers are aware of this feature.

Get the worth of money back from the device. The first investment of $800-1500 for hydraulic types is recouped quite fast by the new rate of production; thus, the overall term is now very favorable.

Select the Type of Attachment Best for You:

Choosing the Correct Thumb

Manual Fixed Thumb

- Design: Traditional and old-fashioned thumb; solid pin or weld-on thumb; in a fixed position.

- Pros: Budget-friendly, uncomplicated.

- Cons: No way of changing the angle; hence, the thumb is not very practical; not many contemporary users are even aware of this type.

Permanent-Mount Hydraulic Thumb

- Design: Fastened to the stick by a base plate, with a separate cylinder doing the work.

- Pros: The whole operation is regulated from the cab, a full array of angles is gripped with precision.

- Cons: This system has the downside of requiring both extra hydraulic power and network.

- Ideal for: Regular heavy use, diverse material handling operations, etc.

Coupler-Mounted Hydraulic Thumb

- Design: Connected by a quick coupler; it does not go off even when a bucket is switched.

- Pros: No chance of losing the attachment; it is still consistent after the replacement of buckets.

- Cons: The main problem is that it will be long as being extended to where the bucket is and requires match bucket positioning.

Stick-Mounted Hydraulic Thumb

- Design: It is linked to the stick and works independently of the bucket.

- Pros: The main foci are the accuracy of the barrel when it is aligned and the best for applications that are gradually closing.

- Cons: The process will be slightly longer because there will be some more welding as well as the fitting that will follow afterwards.

Progressive-Link Thumb

- Design: The apparatus has an extra component to enable the movement of the thumb to tilt sidewards thereby having a greater level of rotation.

- Pros: The ability to have a compact thumb during a full retractron of the extra link’s extended means of rotation is the best solution, in addition, it also helps in reducing the risk of clashing.

- Cons: It is heavy on components and intentions, and therefore its overall cost is quite high.

Compatibility Among choosing Right Thumb Attachment

Ensure the finger size is compatible with the machine model, the pin size of the stick, and the width of the bucket. There are universal thumbs—however, you must double-check the dimensions to be sure.

Hydraulic Requirements

When only auxiliary hydraulic circuits are there, opt for a hydraulic thumb.

Material & Weld Quality

Inspect that full-penetration welds and high-grade steel are used to steer clear of bending and wear problems.

Application—Match Thumb Type to Task

| Task Type | Thumb Type |

|---|---|

| Heavy logs, demolition | Hydraulic main-pin or stick-mounted |

| Landscaping, mulch | Hydraulic thumb |

| Light-duty debris | Fixed thumb |

| Frequent bucket changes | Coupler-mounted thumb |

Size & Fit

- Length: The length should match your machine’s operating weight. For example, a 4,000 to 6,000 lbs unit, requires an approximate 21″ long thumb.

- Width: The width of the thumb should be the same as the bucket to ensure a strong grip. Most universal thumbs are ~7″ wide, but others 10″, 14″+, etc. are also available.

Thumb Install or OEM?

Thumbs fixed in factories are the best—bracket-ready models will be easier to add as an option.

A professional welder, along with hydraulic connections and pressure tests, needs to be carried out in a retrofit installation, unless there are brackets that are pre-installed.

Installation & Maintenance

It is advisable to get professional assistance for the installation, particularly with hydraulic thumbs that need welding, pipe fitting, and pressure testing.

- Frequent checks: the condition of pins, bushings, welds, and hydraulic lines should be checked for wear, leaks, and lubrication — this activity is the best way to prevent breakdowns and prolong the machine’s life.

- Keep it clean: Only the debris that is capable of causing the equipment to seize must be taken away.

When You Don’t Need a Thumb

Just think about your work if most of it deals with materials like topsoil, sand, small rocks, or pebbles, and if you don’t deal with the large rubble and there will be less than the normal amount of it, then you should definitely abandon the thumb since using a bucket is no different without one. For regular trenching, grading, or loading gravel by the bucket, it’s just a waste of money.

Thumb Attachment Products from American Excavator

The American Excavator Store offers:

The Budget Style Hydraulic Thumb Clip ~$300 – for machines under 3 tons & hydraulic operation lacking any extra features, just plug-n-play hydraulic the thumb.

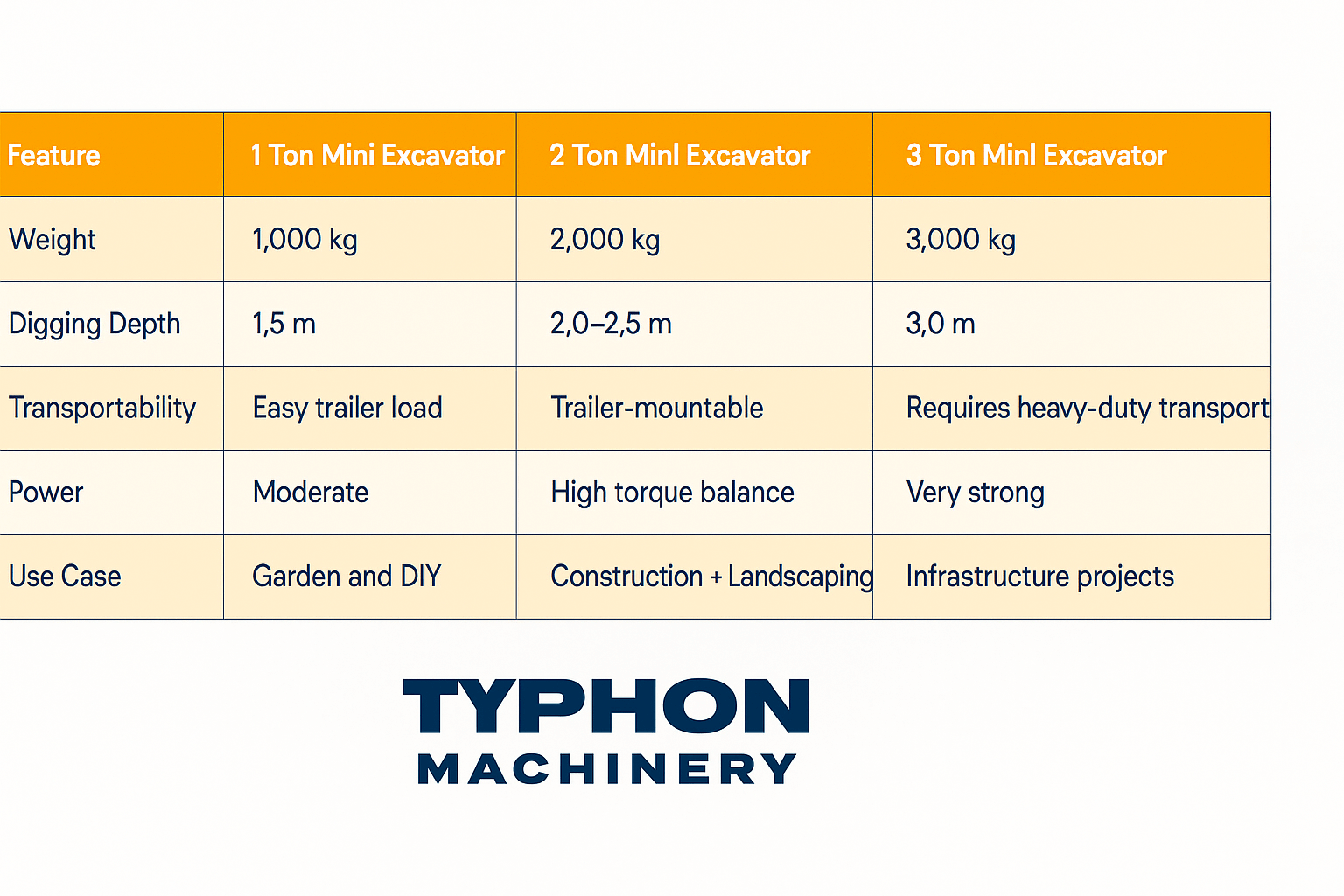

A Hydraulic Thumb Clip for the TYPHON range – similarly priced, also the platform, the new-style, green machine excavators.

These cost-effective, sturdy options bring about the productivity you need efficiently and without having to pay the premium prices.

ROI & Real-World Examples

Hydraulic-thumb users report:

They spend 45% less than MSRP, however, the increase in resale value and productivity that exceeds the cost make the purchase profitable.

It also provides safety and a guarantee that unwanted materials will be handled carefully which is good for the local communities and the environment in general.

Final Takeaway: The Thumb is Fundamental

One of the mini excavator applications far outweighs the mere digging function which is a problem solver while only having the right tools. That thing is being a trench-digger when it is equipped with a thumb. Such versatile construction equipment may be used for various tasks like placing stones, uprooting stumps, and even clearing the debris. The thumb is so powerful like the tractor so multifunctionality is guaranteed.

Simply put, you can fulfill the following with the equipment:

- Release potentiality: have the thumb and the bucket and you have unlocked the full potential of the instrument as it now is multifunctional to the extreme.

- Fuel economy: no need of extra time, workers, or workforce.

- Security “top of the list”: handling the materials firmly and no accidents.

You will also augment your equipment’s price if you sell the thumbs as they add value to your product. The fact is that your future customers will undoubtedly be glad of it.

By virtue of the convenience it provides for money-saving and security reasons in the line of duty, as well as its superior product performance, the thumb attachment seems to be indispensable for every mini excavator.

Next steps in case you’re already good to go: Are You Ready?

Examine the pin sizes, hydraulics, and bucket dimensions of your machine.

Ensure your typical tasks and materials are in order.

Pick thumb variety according to the usage frequency and its level of difficulty.

Talk to the dealer or a mechanic and get their advice for the installation.

Commence the utilization and measuring of the proficiency gains — thumbs soon will be one of the tools you won’t be able to live without.

Appendix: Quick Guide to Thumb Types

| Thumb Type | Cost | Requires Hydraulics? | Installation Complexity | Best For |

|---|---|---|---|---|

| Manual Fixed Thumb | Low | No | Easy | Occasional use, budget-focused |

| Permanent Hydraulic Thumb | Mid–High | Yes | Moderate to Complex | Frequent handling, heavy materials |

| Coupler-Mounted Thumb | Mid–High | Yes | Moderate | Quick bucket swaps |

| Stick-Mounted Thumb | Mid–High | Yes | Complex | Precision work, close-to-cab operation |

| Progressive-Link Thumb | High | Yes | Complex | Maximum rotation, tight street conditions |

FAQs:

Do I really need a thumb for my mini excavator?

Without any doubt, you definitely should if you have to handle irregular materials such as rocks, logs, brush, or demolition debris on a regular basis. A thumb will turn your machine into a multifunctional instrument, which can not only scoop and dump but also grab, hold, and place the goods. This way, it’s not only time- and labor-saving for the person who does gardening, construction, and infrastructure work but also the most efficient way of doing things.

Can I install a thumb on my existing mini excavator?

Indeed, many mini excavators are openly set up to be matched with the thumb attachments which are sold in the market. These are the steps you need to do:

- Check the stick pin diameter and bucket width

- Confirm if you have the auxiliary hydraulics required for a hydraulic thumb

- Select the suitable model, i.e., manual or hydraulic according to your needs

Some models are designed to fit the thumb attachment with brackets already installed, thus it becomes a much easier task to mount the thumb.

What’s the difference between a manual and hydraulic thumb?

Manual thumbs are non-adjustable and fixed in one place. They are simple in construction and thus cheaper, but you have fewer opportunities to use them.

Hydraulic thumbs are usually activated by the use of hydraulic power from the operator’s cab and are fully functional and are practical for frequent use and if heavy duty is needed.

Given this information, it is clear that if there is a lot of lifting to do and the task is tough, then the purchase of hydraulic one will be a good return.

Can I switch buckets with a thumb installed?

Yeah, of course, but it would be mostly the way a thumb is mounted which frequently determines if quick-change bucket use is possible.

Hydraulic thumbs attached to the stick are more versatile but can probably be unleashed and adjusted a few times to engage better with the different bucket profiles.

Find a set of thumbs that have truly universal design or quick-coupler compatibility if you frequently replace attachments.

Will a thumb interfere with my bucket operation?

If both are installed and sized correctly, the thumb will not be in conflict with the work of the bucket. An appropriately designed thumb will be folded and will not cause any trouble when turning in the idle position as well as be not rigidly fixed in the middle of the way during the action of the machine. The so-called ‘tilt-link’ thumbs can give additional angles of rotation and at the same time help to reduce the possibility of hitting the boom.