The primary purpose of mini excavators is to perform precise and efficient work in confined spaces. Their popularity has been mainly driven by the need for these machines in the construction, landscaping, agriculture, and infrastructure sectors, not only for small-scale digging but also as tech-savvy, powerful, and nimble units. Let’s learn the essential mini excavator parts to get a complete description.

It is quite helpful to know the features of a mini-excavator and mini excavator parts. Learn what each part does if you happen to be a contractor, a business owner, or a fleet manager. TYPHON Machinery is a professional and reliable partner in the mini-excavator business who can provide you with excellent machines for various working conditions of your projects, support you well after the sales, and offer you top-quality spare parts.

Undercarriage: Stability and Maneuverability

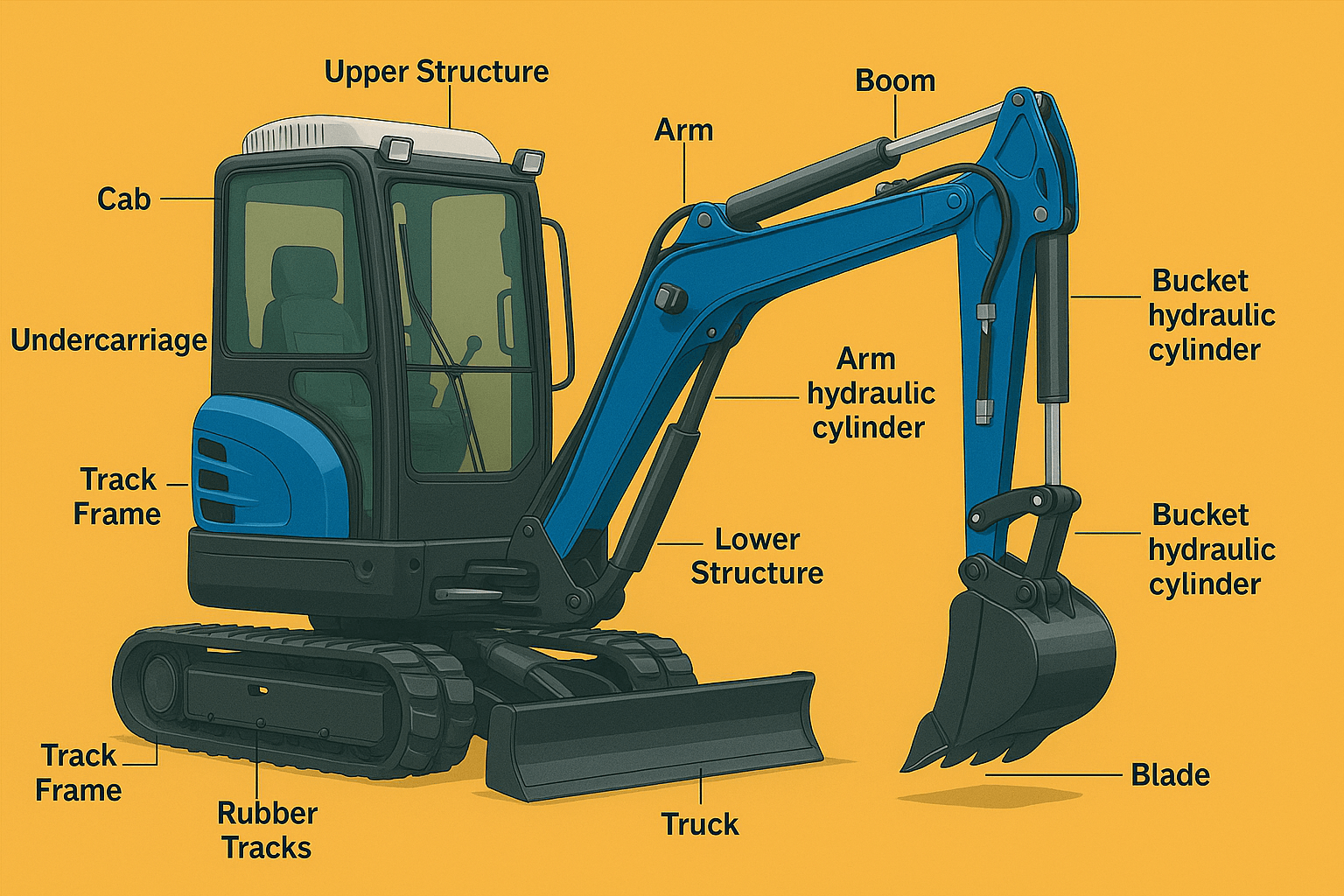

An argument could be put forward that the undercarriage is the part of the structure that is basically the root, which not only holds the rest of the frame but also gives the machine the ability to move. It is the strong build of the undercarriage with which small excavators are fitted that makes them capable of going on rough, uneven, or even delicate terrains without falling or slipping. The very first features of the undercarriage are:

- Rubber tracks: They provide the necessary grip, lessen the impact on the ground, and make the movement simple and maneuverable in limited spaces.

- Track frame & rollers: Made of long-lasting ballistic material, they guide the tracks precisely and vibration-free by the cab.

- Travel motors: These are the reason for the changes from speed to power that are most of the time doubly quick and smooth between the different work zones with a little period of downtime.

The dozer blade is a component of the undercarriage that plays a vital role in leveling, stabilizing, and pushing back the earth. It also helps stabilize the excavator on uneven ground. Like track tension, dozer blade maintenance is a part of everyday work in the field.

Operator Cab: Command and Comfort

The cab is the place of control where ergonomic design is blended with the most up-to-date control technology. Operators can enjoy:

- 360-degree visibility: Makes the worksite much safer.

- Easy-access controls: Efficient joystick layout for controlling boom, arm, and bucket. 2

- Isolation from vibration and noise: Noise and vibration are limited through the use of specially designed engine mountings and cab insulation. To the operator this means more comfort, especially during long working hours.

Moreover, there can be adjustable seats, temperature controllers, and logical monitoring displays—some of the comforts that come standard with leading mini excavators like the TYPHON range.

Upper Structure: Power and Precision

The upper structure sits on the undercarriage and includes the engine and hydraulic system, along with the counterweights. It has infinite rotary motion; thus, the operator can effortlessly change the position of the machine without having to move the tracks.

- Engine compartment: May consist of advanced diesel or electric power sources for clean, quiet, and efficient operation, depending on the model.

- Counterweight: Works against the forces of lifting and digging; it stabilizes the machine during heavy lifts or when the arm is extended far out.

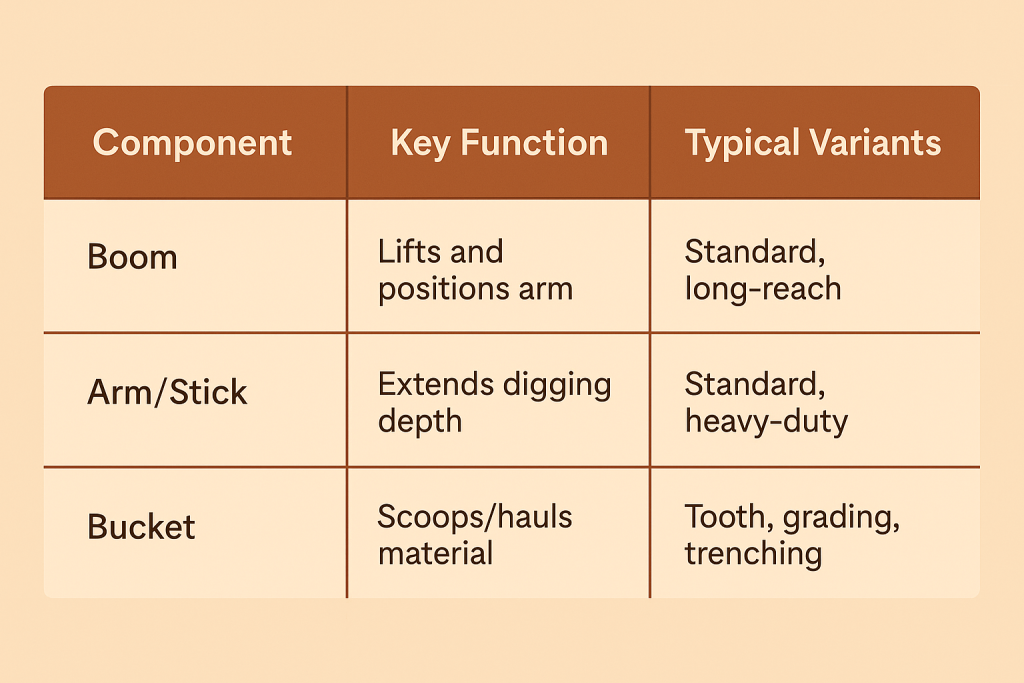

The Boom, Arm (Stick), and Bucket are the core components that provide the mini excavator with its versatility. These parts are what give the mini excavator the core versatility of the machine.

- Boom: The primary load-carrying element goes up and down to locate the stick.

- Arm (stick or dipper): Connects the boom to the bucket; the reach and depth are increased for excavating and trenching.

- Bucket: Can be changed and is optional, thus enabling the performance of a wide range of tasks from earthmoving and grading to demolition and material transport.

Key Workgroup Dimensions and Functions

Hydraulic System: The Force Multiplier

Basically, a perfectly designed hydraulic system is what provides the mobility and versatility of the attachment of a mini excavator. With the help of strong, high-pressure fluid circuits, it is the one that operates the boom, stick, and bucket. Key aspects to understand include

- Accuracy of the control system: The pilot valves enable the operator to carry out smooth, very responsive, and accurate operations.

- External hydraulic connectors: Could be employed as a prop system for a plethora of different attachments—from augers to breakers.

- Upkeep suggestions: Changing the machine’s filters regularly and always using clean oil will make the machine work for a long time.

Dozer Blade: Multi-Purpose Efficiency

The dozer blade is a component that is typically included as standard equipment with mini excavators and is very helpful for stabilizing, backfilling, leveling, and clearing debris. Its robust construction is able to take the most severe field structures—thus, it is the finishing-site-work tool of choice.

- Stabilizer during digging: Gives extra mass to counterbalance the tipping-off dangers.

- Quick grading adjustments: Leveling or filling work areas is done in a very short time and with minimum effort.

- Wear monitoring and replacement: The blade edges should be checked for unevenness, especially after doing abrasive work.

Tracks and Undercarriage Components: Built to Last

The robustness of the tracks (either rubber or steel), track shoes, and other components such as sprockets and rollers that go8 along with the machine is very important for the lifespan of the machine.

- Track tension: Ensuring the correct track tensioning is the main point in the prevention of track derailing and thereby of an excessive wear situation.

- Sprocket engagement: The connection between the sprocket and the engine that results in the machine being able to move efficiently.

- Rollers and idlers: These carry the weight, lessen the rattling, and facilitate a smoother ride of the machine over different terrains.

Swing System: Rotates 360 degrees without any gaps

The swing gear, along with the hydraulic motor 10, enables the upper structure to turn 360 degrees, thereby being able to do work like digging, loading, and trenching in a much more efficient way, as the need to reposition the undercarriage is no longer there.

- Swing motor and ring gear: These are the elements that take the energy of the fluid in the hydraulic system and change it into gradual, exact rotational movement.

- Swing lock: Very useful and, most importantly, a safety feature during transport or maintenance, as it keeps the house aligned with the tracks.

- Counterweight integration: It is the main factor that allows for a balanced and smooth operation, as it offsets the weight of the upper structure.

Attachments: Maximizing Versatility

The defining feature of mini excavators is their adaptability, which is facilitated by various attachments that utilize a quick-coupler hydraulic system for support.

- Buckets: The range is from trenching to ditch cleaning.

- Hydraulic breakers, augers, and rippers can be used for demolition, boring, soil loosening, and other such activities.

- Sorting grapples and thumbs: The best choice for material handling or site cleanup.

In addition to these, the regular application of grease and prompt replacement of hydraulic hoses and pins will keep the performance and reliability of your attachment at a high level.

Electrical System: Powering Modern Tech

The present-day mini excavators come with advanced electrical mini excavator parts:

- LED work lights and display monitors help the operator in being more aware and tracking his performance.

- Electronic engine controls: Lead to better fuel efficiency and emission management.

- Telematics: Provide the possibility for troubleshooting from a distance and managing the fleet, especially in the case of TYPHON’s premium products.

Maintenance Points: Keeping Excavators Job-Ready

Regular upkeep will help to keep the downtime minimal and the investment safe:

- Grease all the pivot points and linkage pins regularly to reduce the wear.

- Always monitor the fluid levels (engine oil, hydraulic fluid, and coolant) on a daily basis.

- Examine and clean the air filter, and put a new one when it is time, especially in places where there is a lot of dust.

- After finishing your work, make it a habit to thoroughly check the undercarriage for any possible damage or debris.

Customer Support and After-Sales Service

TYPHON Machinery emphasizes robust after-sales support:

- Wide range of spare parts: Makes the quick replacement of most of the frequently worn parts possible.

- Technical Assistance: Skilled technicians solve problems, reduce downtime, and boost productivity.

- Customizable service intervals: Depend on the intensity of the usage, thereby allowing the user to save money and increase his working time further.

FAQs About Mini Excavator Parts and Functions

What are the main mini excavator parts?

Mini excavator parts are composed of the following main parts: the undercarriage, cab, upper structure, boom, arm, bucket, hydraulic system, electrical system, and auxiliary attachments. Each of these parts has different roles in the operation and versatility of the machine.

How often should parts of a mini excavator be maintained or replaced?

Main components like filters, tracks, and hydraulic hoses should be checked regularly, and the replacement of parts such as track tensioners, pins, and bushings should be done according to the hours of use or visible wear condition.

Is it possible to upgrade my bucket or other attachments?

Certainly, mini excavators are built to be compatible with a wide array of different types of buckets and other hydraulically powered tools through quick-coupler systems.

What are mini excavator tracks designed to last?

Generally, the lifetime of rubber tracks can be from 1,200 up to 2,000 hours, and it is mostly dependent on the terrain as well as the manner of maintenance, whereas steel tracks are usually more durable but suitable for rougher surfaces.

Does operator comfort affect part longevity?

Definitely, a comfortable, well-insulated cab will significantly contribute to the lessening of the exposure to vibrations, thereby, both the machine and the operator will be more protected during longer periods of work.

Which hydraulic components are most susceptible to wear?

The most vulnerable to wear are the seals, hoses, and connectors, and these parts should be checked frequently and for any leaks or cracks.

What changes have been made to mini excavator designs for the year 2025?

Among the reasons for the change in design of new models are electrification, quieter operation, advanced telematics, and easier attachment changes, thus both contractors and rental fleets being better served.

Best Investment Option—Mini Excavator Parts:

Invest in mini excavator parts for excellence. The result of choosing to work with a mini excavator while you have a thorough understanding of the purpose and the upkeep needs of each part is success on the jobsite.

The TYPHON Machinery complete line—customer-inspired upgrades and dedicated service—is the answer to compact performance with durable precision. The mastery of mini excavator anatomy is the key to most efficient use of time, ROI, and operational excellence regardless of whether you are managing large developments, residential landscapes, or municipal infrastructure.