What exactly is an Electric Forklift?

If you walk into a modern distribution center today, you might notice something strange: the silence.

Gone is the constant roar of diesel engines and the smell of exhaust fumes. In their place is the faint hum of tires on concrete. This is the era of the electric forklift.

But what is it, really? Is it just a standard forklift with a battery shoved in it, or is it a completely different beast?

An electric forklift is a type of material handling vehicle that runs on a big battery and an electric motor instead of an internal combustion (IC) engine that runs on gasoline, propane, or diesel. That sounds easy, but the technology inside makes it one of the most powerful machines in the world.

This article delves into the inner workings of electric forklifts, the reasons behind their popularity among businesses, and the essential knowledge you should possess before operating one.

The Anatomy: How It Works

To understand the electric forklift, you have to stop thinking about “engines” and start thinking about “energy flow.”

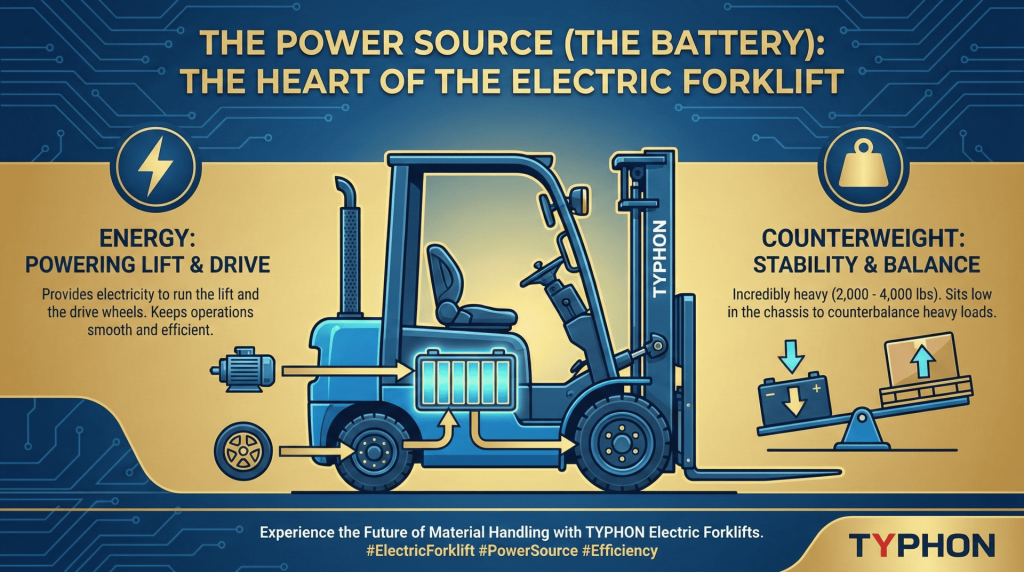

1. The Power Source (The Battery)

In a gas forklift, you have a tank of fuel. In an electric forklift, the battery is the heart of the machine. It serves two massive purposes:

- Energy: It provides the electricity to run the lift and the drive wheels.

- Counterweight: These batteries are incredibly heavy (often weighing 2,000 to 4,000 lbs). They sit low in the chassis to counterbalance the heavy loads you lift on the forks.

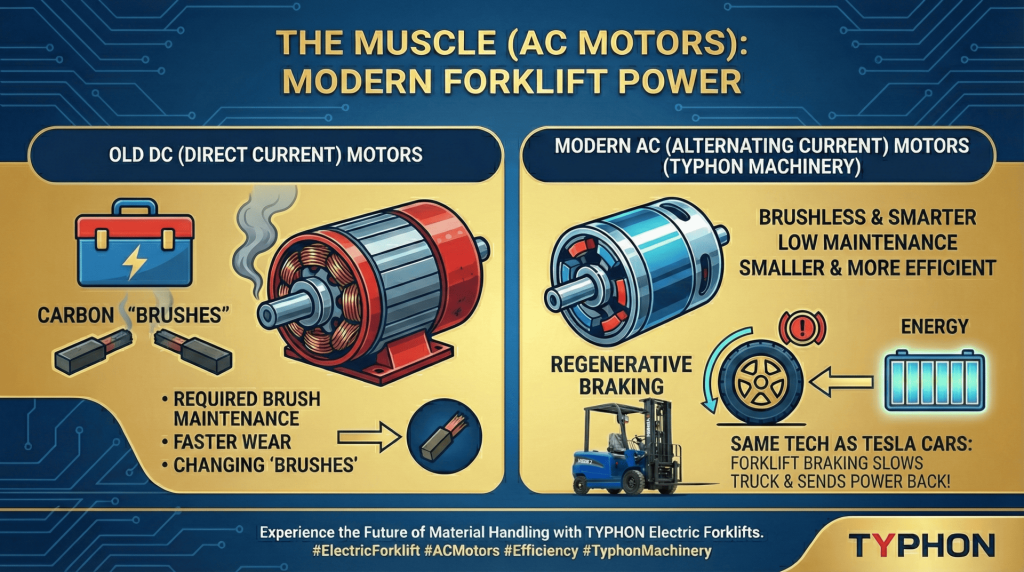

2. The Muscle (AC Motors)

Old electric forklifts used DC (direct current) motors, which were decent but required a lot of maintenance (changing “brushes”).

- Why the change matters: AC motors are brushless. They don’t wear out as fast, they are smaller, and they are smarter. They allow for “regenerative braking”—meaning when you take your foot off the gas, the motor slows the truck down and sends power back into the battery. It’s the same tech used in Tesla cars.

3. The Brain (The Controller)

This is the computer board that manages the heat, the speed, and the power. It ensures that when you press the accelerator, you get smooth acceleration rather than a jerky start that could topple a load.

The Two Big Battery Technologies

If you are looking into what an electric forklift is, you cannot ignore the battery type. This is usually the biggest debate for buyers.

- Lead-Acid (The Old Guard) This is the same tech found in your regular car battery, just scaled up massively.

-

- The Reality: They are cheaper to buy upfront, but they are high-maintenance. Regular watering—that is, pouring distilled water into the cells—is necessary to keep them alive. They also take about 8 hours to charge and another 8 hours to cool down.

- Who is it for? Warehouses that run one shift a day (9-to-5).

- Lithium-Ion (The New Standard) These are sealed batteries, similar to what is in your phone or laptop.

-

- The Reality: They cost more upfront, but they are “maintenance-free.” You can plug them in during a 15-minute lunch break (“opportunity charging”) without damaging them. They last 2–3 times longer than lead-acid batteries.

- Who is it for? They are used in busy 24/7 operations that cannot afford to halt.

Why the Shift? (Electric vs. Propane)

Why are people dumping their reliable propane trucks for electric ones? It usually comes down to three things: money, health, and silence.

- The cost factor sticker shock is real. An electric forklift often costs more to buy than a propane one.

-

- However… electricity is cheap. Propane is expensive.

- An electric forklift has no engine oil, no transmission fluid, no spark plugs, and no radiator. The maintenance expenses are roughly 30–40% lower. Most companies break even in about 18 months; after that, it’s pure savings.

- The Indoor Factor You cannot run a diesel forklift inside a closed warehouse without massive ventilation—the carbon monoxide will kill you. Even propane releases fumes. Electric forklifts produce zero emissions. This makes them mandatory for food handling, pharmaceuticals, and cold storage.

- Operator Fatigue It sounds minor, but the vibration and noise of an engine exhaust an operator over an 8-hour shift. Electric trucks are smooth and silent. A happier, less tired operator is a safer operator.

Common Misconceptions

Let’s clear up a few myths about what an electric forklift is and isn’t.

- Myth: They are weak. Reality: False. Modern electric trucks have incredible torque. Because electric motors provide instant power (no need to rev the engine), they can push and lift just as powerfully as their internal combustion rivals. You can now buy electric forklifts that lift 40,000+ lbs.

- Myth: You can’t use them outside. Reality: It depends. If you have a standard warehouse forklift with “cushion tires” (hard rubber), then no—it will get stuck in the mud. But if you buy an electric forklift with “pneumatic tires” (air-filled) and weather sealing (like the outdoor-rated models from Typhon), they handle the yard just fine.

- Myth: The battery dies halfway through the day. Reality: A properly sized battery will last a full 8-hour shift. If you are running multiple shifts, you simply swap the battery or use a fast-charging lithium-ion setup.

The Shift to Electric Material Handling

The material handling industry is undergoing a massive transformation. Ten years ago, if you needed to move heavy pallets in a foundry or a lumberyard, you bought a diesel or propane lift truck. Electric trucks were considered light-duty machines restricted to clean, indoor warehouses.

This narrative has entirely changed. Today, high-voltage electric forklift machines are matching internal combustion (IC) engines in torque and lifting capacity while offering a lower Total Cost of Ownership (TCO). For warehouse managers and manufacturing owners, the question is no longer “Should we go electric?” but rather: “Which electric technology fits our operation?”

This guide explores the engineering, the economics, and the practical realities of deploying electric material handling equipment in modern facilities.

Electric Forklifts in USA

Electric forklifts are powered by an electric motor and are used to handle, transport and lift materials. VIGOR electric forklifts by TYPHON Machinery are often used for indoor operations in warehouses, refrigerated store rooms and airport terminals. Electric forklifts have several advantages over diesel and gas forklifts, including:

- Lower costs of operations: Electric forklifts can result in 80% savings when compared to diesel trucks.

- Environmentally friendly: Electric forklifts have zero emissions and result in a smaller environmental footprint than other forklifts.

- Greater maneuverability: Electric forklifts have a smaller turning radius and can respond accurately to operator commands.

- Better visibility: The battery is positioned beneath the operator's seat, which improves visibility and safety.

- Quieter: Electric forklifts create less noises than other types of forklifts.

- Less maintenance required: Electric forklifts require less maintenance than other types of forklifts.

How Modern Electric Forklifts Work

Unlike the internal combustion engines that rely on exploding fuel to drive pistons, an electric lift truck relies on a much simpler, more efficient drivetrain.

The Power Source

The heart of the machine is the battery. It acts as both the fuel tank and the counterweight. This heavy battery sits low in the chassis, giving electric forklifts a lower center of gravity than their propane counterparts, which improves stability during high lifts.

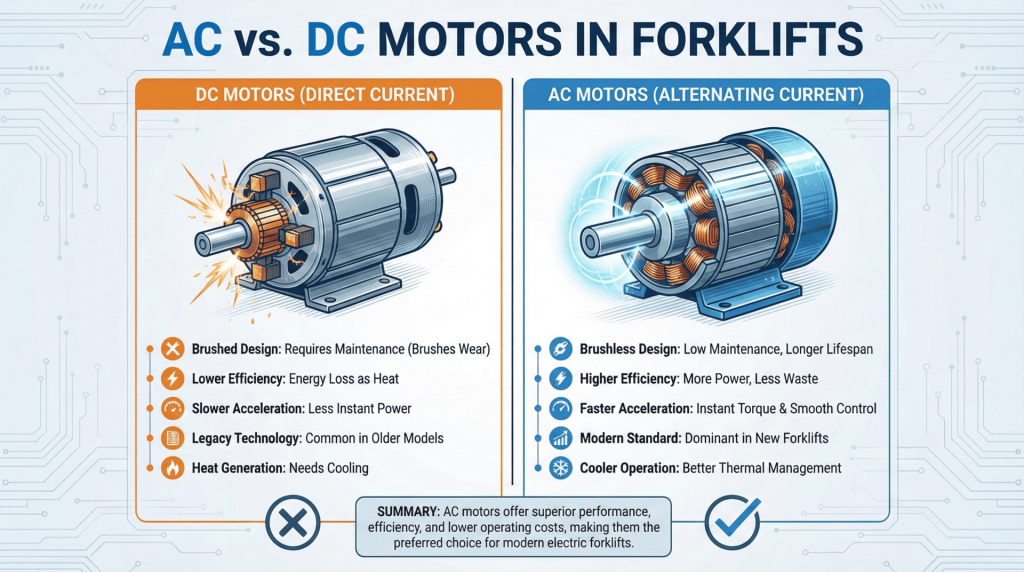

AC vs. DC Motors

Direct Current (DC) motors were used in older electric trucks. They were reliable, but they tended to overheat and needed new brushes often. Many modern industrial electric forklifts, including those made by Typhon Machinery, use alternating current (AC) motors.

AC motors are brushless, meaning less friction and less wear. They provide:

- Regenerative Braking: When the operator lets off the accelerator, the motor reverses to slow the truck down, sending energy back into the battery.

- Precise Control: Better handling at low speeds, which is critical for placing expensive inventory in high racks.

- Higher Torque: Immediate power delivery without needing to “rev up” the engine.

Battery Technology: Lead-Acid vs. Lithium-Ion

When you shop for an electric forklift price, you aren’t just buying the truck; you are buying the power system. This is the most critical decision you will make.

1. Traditional Lead-Acid Batteries

This is the technology that has been around for decades. It is heavy, reliable, and inexpensive upfront.

- Pros: It costs less to buy at first, and the heavy weight is a useful counterbalance.

- Disadvantages: needs a lot of care (needs to be watered); takes a long time to charge (8 hours to charge and 8 hours to cool down); and lasts for a shorter time (about 1,500 cycles).

- Best For: Single-shift operations where the truck sits idle overnight.

2. Lithium-Ion (Li-Ion) Batteries

This is the modern standard for high-throughput warehouses.

- Pros: Zero maintenance (sealed units); allows for “opportunity charging” (plug it in during a 15-minute coffee break); consistent power output until the battery is dead; longer lifespan (3,000+ cycles).

- Cons: Higher upfront cost.

- Best For: Multi-shift operations (24/7 warehouses) where swapping batteries out is a waste of time.

If you are running a Typhon electric forklift in a busy distribution center, upgrading to a Li-Ion setup often pays for itself within two years by eliminating the labor cost of battery maintenance and swapping.

The Economic Case: ROI and Total Cost of Ownership

Many small and medium business (SME) owners get sticker shock when they see the initial cost of an electric unit compared to a propane one. An electric truck might cost $10,000 to $15,000 more upfront than a comparable IC truck.

However, the electric warehouse forklift wins on operational expenses (OpEx).

Fuel Savings

Electricity is cheaper and more price-stable than propane. Charging a standard battery might cost $2–$4 per shift in electricity. A tank of propane can cost $20–$35 per shift. Over five years, this difference alone can amount to $20,000 in savings per truck.

Maintenance Savings

An IC engine has hundreds of moving parts. It needs oil changes, filter changes, coolant flushes, and transmission service. An electric forklift machine has no crankcase oil, no radiator, and no spark plugs. The primary maintenance involves greasing fittings and checking hydraulic fluid.

The ROI Horizon

For a facility running trucks 6 hours a day, the break-even point—where the electric savings overtake the higher upfront cost—is usually between 18 and 24 months. Thereafter, the electric truck is significantly more profitable to run.

Brand Spotlight: Typhon Machinery Electric Forklift

In the US market, buyers often feel trapped between ultra-expensive premium brands and cheap, unreliable imports. This is where Typhon Machinery has carved out a niche.

The Typhon electric forklift series is designed for the practical user—construction sites, equipment rental companies, and heavy-material warehouses.

Why Typhon Works for SMEs:

- Simplicity: They avoid over-engineering. The controls are intuitive, meaning temporary operators or rental customers can jump in and work safely without a week of training.

- Durability: Coming from a lineage of heavy excavators and skid steers, Typhon builds their forklift chassis to take a beating. They are robust enough for light outdoor work on improved surfaces.

- Value: They offer competitive specs (lift height and capacity) at a price point that makes sense for businesses that cannot afford to spend $60,000 on a single lift truck.

If you are looking for a zero-emission forklift that retains the rugged feel of construction equipment, Typhon is a strong contender.

Critical Application: Indoor vs. Outdoor Use

Can you use an electric forklift outside? This is a common point of confusion.

The Indoor Advantage

For food processing, pharmaceuticals, and tight warehousing, electric is mandatory. You cannot have carbon monoxide fumes in these environments. The indoor electric forklift is also quiet, which reduces noise pollution—a major fatigue factor for workers.

The Outdoor Reality

Historically, electric trucks couldn’t handle rain or rough terrain. However, newer models with higher IP (Ingress Protection) ratings can handle light rain.

- Tires Matter: If you plan to go outside on asphalt, you need pneumatic (air-filled) or solid pneumatic tires. Standard “cushion” tires are for smooth concrete only. If you take cushion tires on gravel, you will chip them apart in weeks.

- Ground Clearance: Electric forklifts typically have lower ground clearance to protect the battery. If your yard has deep potholes or mud, you might still need a specialized rough-terrain electric model or stick to diesel.

Operational Safety and OSHA Compliance

Switching to electric introduces new safety protocols that managers must enforce.

Battery Safety

If using lead-acid batteries, charging areas must be well-ventilated. Even though the truck emits no fumes, a charging lead-acid battery emits hydrogen gas, which is explosive. You need an eyewash station nearby in case of acid spills.

- Note: Lithium-ion batteries do not gas, so they don’t require special ventilation rooms.

Pedestrian Awareness

The greatest safety benefit of an industrial electric forklift (silence) is also a hazard. Pedestrians cannot hear the truck coming around a blind corner.

- Best Practice: Install blue light spotters on the front and rear of the truck. These project a blue dot on the floor about 10–15 feet ahead of the machine, visually warning pedestrians of an approaching vehicle.

Maintenance Checklist for Long Life

To enjoy 10 years out of your investment, follow this simple maintenance schedule.

Daily:

- Visual Inspection: Check for hydraulic leaks on the floor.

- Tires: Check for “chunking” or embedded debris (wire, plastic wrap).

- Brakes: Test braking distance at low speed before starting work.

Weekly (For Lead-Acid Batteries):

- Water Levels: Verify water levels after the battery is fully charged. Add distilled water only.

- Cables: Inspect battery cables for fraying or corrosion.

Monthly:

- Chain Tension: Check the mast chains. If they are loose or uneven, the load will be unstable.

- Greasing: Apply grease to the mast channels and carriage bearings to ensure smooth lifting.

Conclusion: Is It Time to Switch?

The data is clear. Unless you are working in deep mud or require 24-hour continuous operation without the budget for lithium batteries, the electric forklift is the superior choice for modern business.

It offers a cleaner workplace, lower monthly bills, and precise handling. For businesses ready to modernize, looking into reliable options like the Typhon electric forklift can provide the perfect balance of performance and budget control.

Actionable Takeaway:

Audit your current fleet. Calculate your monthly fuel spend on propane. If you are spending more than $500/month per truck on fuel, an electric lease or purchase will likely lower your monthly cash flow immediately.

Comparison: Electric vs. Internal Combustion (IC)

| Feature | Electric Forklift | Internal Combustion (Propane/Diesel) |

| Emissions | Zero (Indoor Safe) | High (Requires Ventilation) |

| Fuel Cost | Low (Electricity) | High (Market Dependent) |

| Maintenance Cost | Low (Few moving parts) | High (Engine, Transmission, Cooling) |

| Lifespan | 10,000 – 12,000 hours | 8,000 – 10,000 hours |

| Refueling | Charging (hrs) or Swap (min) | Tank Swap (5 mins) |

| Noise | Silent | Loud (>85 dB) |

| Best Application | Warehouse, food, and cold storage | Outdoor, Lumber, and construction |

Frequently Asked Questions (FAQ)

What is the average electric forklift price?

A new electric forklift typically ranges from $10,000 to $45,000 depending on capacity (3,000 lbs vs. 6,000 lbs) and battery technology. Used models can be found for $10,000 to $20,000. While the upfront cost is higher than propane trucks, the lower operating costs usually offset this expense within 2 years.

How long does a forklift battery last on a single charge?

A standard battery usually lasts for one standard 8-hour shift. However, lifting heavy loads constantly or using attachments (like clamps) will drain the battery faster. 11 lithium-ion batteries can be “opportunity charged” during breaks to extend run time beyond a single shift.

Is the Typhon electric forklift compatible with standard chargers?

Yes, most Typhon Machinery electric forklifts are designed to work with standard industrial 3-phase chargers.

Can electric forklifts lift as much as diesel ones?

Yes. Modern 80-volt electric systems can lift 10,000 lbs or more, matching the performance of diesel trucks for most general warehousing and manufacturing tasks.

Do I need a special room to charge electric forklifts?

If you use lead-acid batteries, OSHA recommends a designated area with ventilation due to hydrogen off-gassing. If you use sealed lithium-ion batteries, you generally do not need a special charging room, allowing for more flexible floor plans.

So, what is an electric forklift?

It is the evolution of material handling. It is a machine that trades the complexity of an engine for the efficiency of a motor.

For a long time, they were considered the expensive, fancy option. Today, with fuel prices rising and environmental regulations tightening, they are simply the smart option. Whether you are running a small back-of-house retail storage or a massive logistics hub, the electric forklift is likely the workhorse you need.