There was a time in the construction world when larger machines were always considered better. If you wanted to move earth, you needed a massive machine that required a flatbed semi-truck to move and a football field to turn around in.

Those days are over.

Enter the mini excavators (often called compact excavators). These machines have completely revolutionized how we build, landscape, and maintain our properties. They are the Swiss Army Knives of the heavy equipment world—small enough to fit through a backyard gate, yet powerful enough to dig a swimming pool or trench a water line in a single afternoon.

Whether you are a seasoned contractor looking to add a versatile tool to your fleet or a homeowner with a serious DIY itch, this guide covers everything you need to know.

What is a Mini Excavator?

At its core, a mini excavator is a tracked or wheeled vehicle with an approximate operating weight from 0.7 to 6 metric tons (though some definitions stretch this up to 10 tons). Like their larger cousins, they feature a boom, dipper (stick), and bucket connected to a cab that sits on a rotating house.

However, the “mini” designation isn’t just about size; it is about accessibility.

The Anatomy of the Compact

What makes these machines distinct is their engineering focus on working in confined spaces.

- The Undercarriage: Most utilize rubber tracks rather than steel (though steel is an option). Rubber tracks reduce damage to paved surfaces and sensitive turf.

- The Blade: Almost every mini excavator comes equipped with a backfill blade (dozer blade). This acts as a stabilizer while digging and a grading tool for pushing soil back into a hole—a feature rarely standard on full-size excavators.

- The Swing: Many minis offer an independent boom swing. This allows the boom to pivot left or right independently of the house rotation, letting you dig a trench right next to a wall without moving the tracks.

Key Takeaway: Consider a mini excavator to be a precision instrument. It lacks the sheer brute force of a 40-ton excavator, but it makes up for it with surgical precision and the ability to go where big machines simply fit.

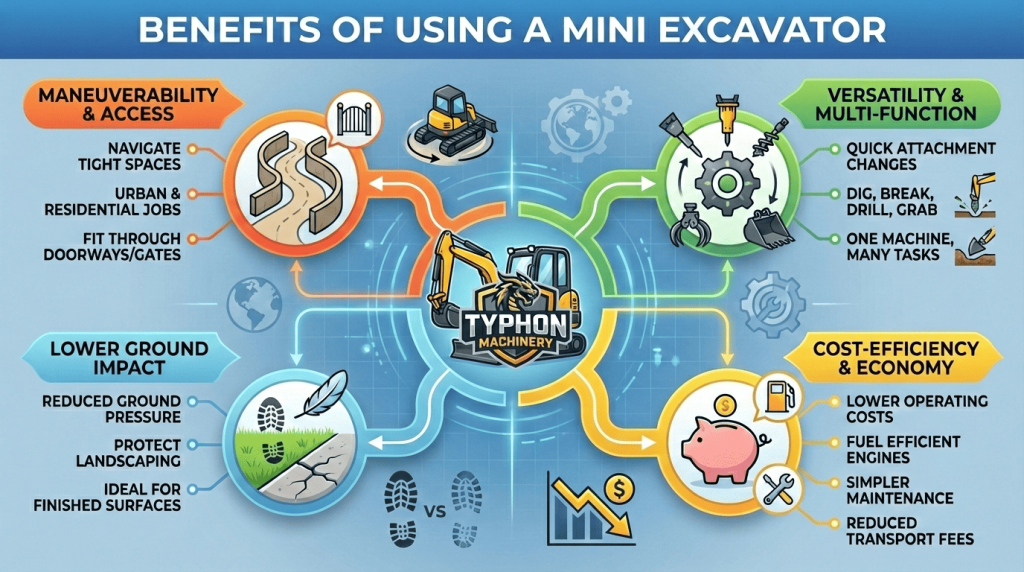

Benefits of Using a Mini Excavator

Why are these machines flying off the dealership lots? The demand for compact equipment has skyrocketed because the nature of construction is changing. Urban density is increasing, and job sites are getting smaller. Here is why the mini excavator is often the MVP (Most Valuable Player) of the fleet.

1. Superior Access and Maneuverability

The most obvious benefit is size. A mini excavator can drive through a standard backyard gate or navigate a narrow alleyway. In roadwork scenarios, they can work in a single lane without shutting down traffic in the adjacent lane. This accessibility opens up a massive range of jobs that would otherwise require manual labor (shovels and wheelbarrows).

2. Less Ground Damage

Heavy equipment creates “ground pressure,” which can ruin lawns, crack driveways, and churn up mud. Mini excavators are lighter. When equipped with rubber tracks, they distribute their weight effectively.

- Benefit: You can drive over a client’s finished driveway or established lawn with minimal remediation required afterward. This keeps customers satisfied and reduces your cleanup costs.

3. Ease of Transport

Moving a standard excavator requires a semi-truck, a low-boy trailer, and special permits.

- The Mini Advantage: Most mini excavators can be towed behind a standard heavy-duty pickup truck (like an F-250 or 2500 series) using a common equipment trailer. This allows for “hit-and-run” efficiency—you can tow the machine to a site, do the job, and leave in a single afternoon.

4. Versatility Through Attachments

A mini excavator is not just a digging bucket. It is a hydraulic power source. With the right attachments, it transforms into:

- A demolition hammer.

- An auger for drilling post holes.

- A thumb for grabbing rocks and logs.

- A brush cutter for clearing vegetation.

5. Lower Operational Costs

They sip fuel compared to larger machines. Maintenance is generally easier because components are smaller and more accessible. Furthermore, the purchase price and insurance costs are significantly lower, offering a faster Return on Investment (ROI) for small business owners.

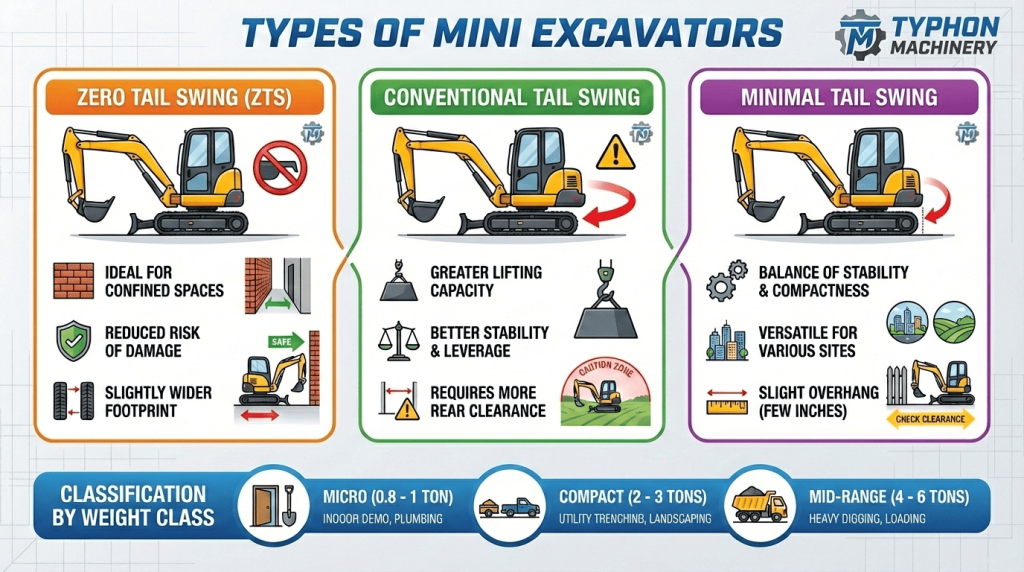

Types of Mini Excavators

Not all mini excavators are created equal. While they may look similar, the differences lie in their tail swing configuration and weight class. Understanding these nuances is critical to picking the right tool.

By Tail Swing Configuration

The “tail swing” refers to how much the rear counterweight overhangs the tracks when the house rotates.

1. Zero Tail Swing (ZTS)

In a ZTS machine, the house rotates within the width of the tracks. The counterweight does not stick out.

- Best For: Working tight against walls, fences, or obstacles. You don’t have to worry about the rear of the machine swinging out and hitting a building.

- Trade-off: This machine generally has a slightly wider footprint to maintain stability, which results in a more cramped cab.

2. Conventional Tail Swing

The rear of the machine extends beyond the tracks during rotation.

- Best For: Open spaces where maneuverability is not the limiting factor.

- Advantage: These machines usually offer greater lifting capacity and stability because the counterweight is further back, providing more leverage. They are also often more comfortable (larger cabs).

3. Minimal Tail Swing

This is a hybrid of the two. The tail protrudes only slightly (usually a few inches). This design attempts to balance the stability of a conventional machine with the compactness of a ZTS.

By Weight Class

- Micro (0.8 – 1 Ton): These often feature retractable tracks to fit through standard doorways. They are essentially powered shovels, perfect for indoor demolition or plumbing retrofits.

- Compact (2 – 3 Tons): The most popular “weekend warrior” size. Many SUVs and light trucks can tow these shovels, which are capable of digging utility trenches and footings.

- Mid-Range (4 – 6 Tons): These bridge the gap. They have a significant breakout force and can load dump trucks, yet they remain relatively compact.

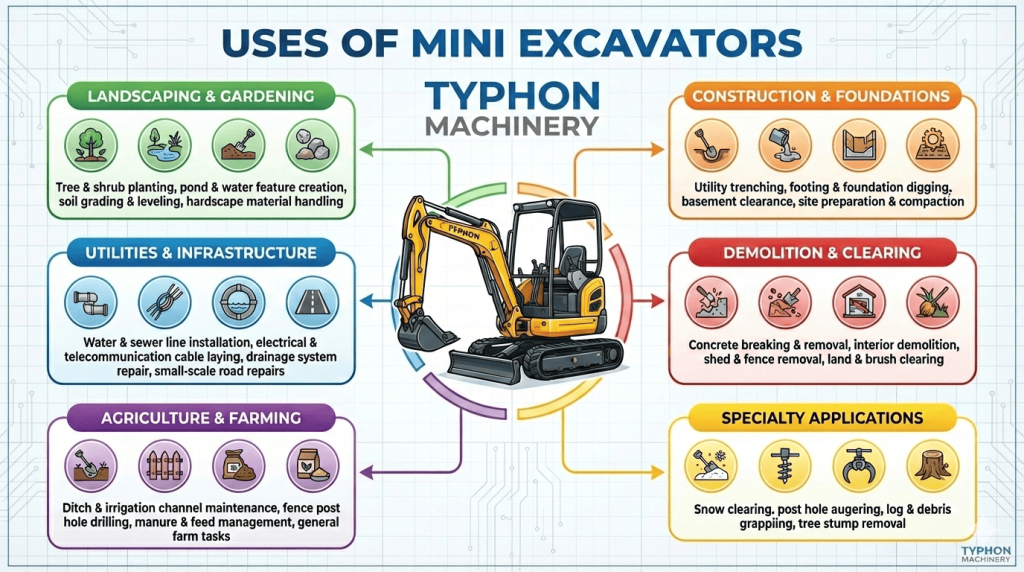

Uses of Mini Excavators

The versatility of these machines is what makes them so attractive. Here is how different industries utilize them.

1. Residential Construction and Landscaping

This is the mini excavator’s natural habitat.

- Digging Footings: For decks, sunrooms, or small additions.

- Pool Installation: While large pools need big excavators, minis are perfect for hot tubs, plunge pools, or tight-access backyard pools.

- Hardscaping: Moving heavy retaining wall blocks and grading soil for paver patios.

- Stump Removal: Using a bucket and a “thumb” attachment to dig around and rip out tree stumps.

2. Utility Installation

Electricians and plumbers love mini excavators.

- Trenching: Digging narrow trenches for water lines, gas pipes, or electrical conduits. Because the bucket can be as small as 12 inches, you don’t excavate more earth than necessary.

- Septic Repair: Accessing septic tanks in established yards without destroying the entire landscape.

3. Demolition

When you equip a mini excavator with a hydraulic hammer (breaker), it transforms into a formidable demolition tool.

- Interior Demo: Micro-excavators can drive inside buildings to break up concrete floors for renovation.

- Concrete Removal: Breaking up old driveways or sidewalks.

4. Agriculture and Farming

Farmers use them for:

- Drilling holes for fencing (using an auger).

- They also clear ditches and drainage channels.

- Moving hay bales or feed bags.

5. Snow Removal

In northern climates, the mini excavator doesn’t hibernate. With a blade or a broom attachment, they are excellent for clearing snow from sidewalks and tight parking lots where plows can’t fit.

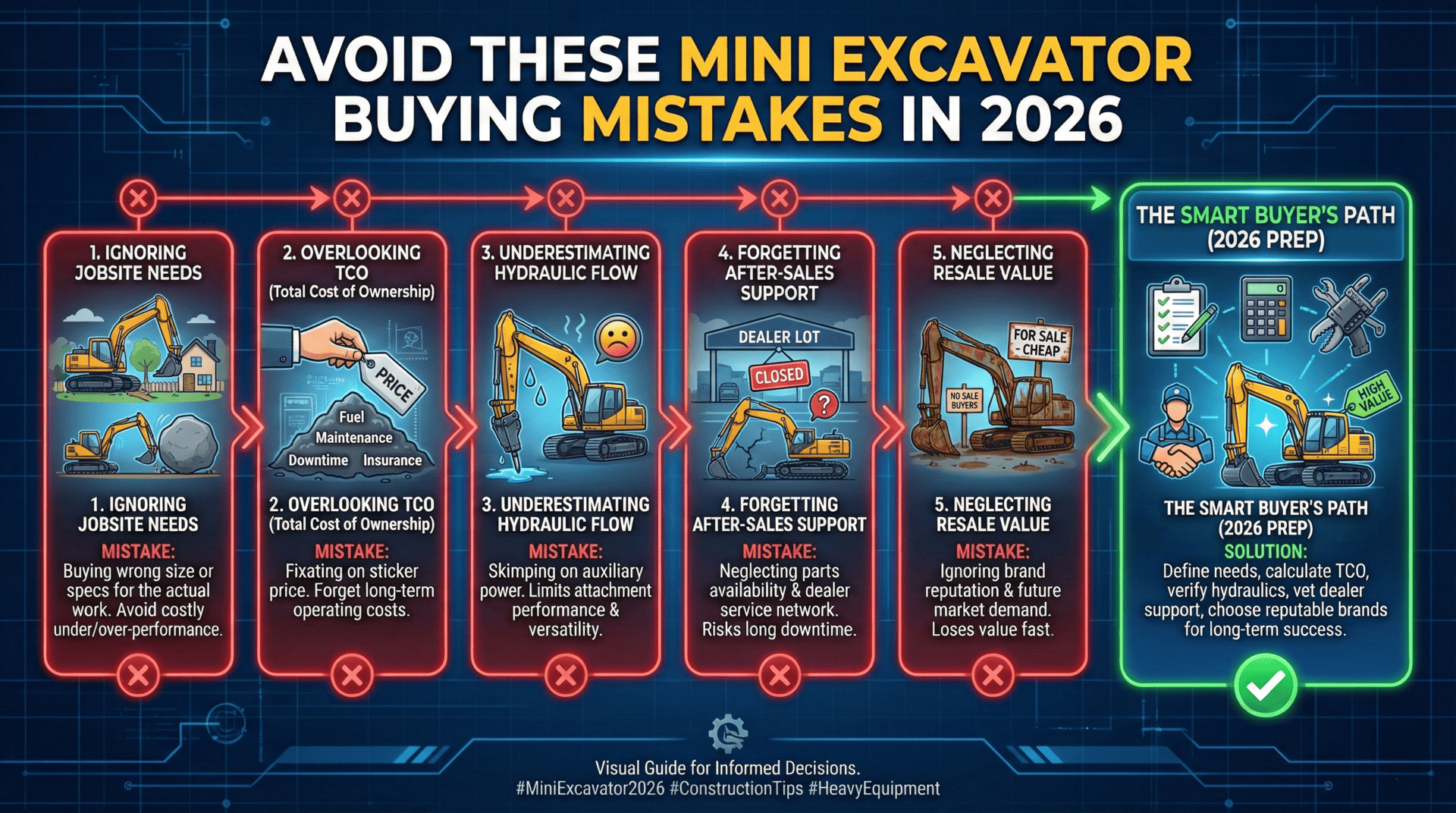

Factors to Consider When Buying a Mini Excavator

Buying a mini excavator is a significant investment, often ranging from $10,000 to over $100,000 depending on the size and brand. To ensure you don’t buy too much machine or, worse, not enough machine, consider these factors.

1. Digging Depth and Reach

Do not guess this number.

- If you install septic systems, you might need a digging depth of 10–12 feet.

- If you only do shallow landscaping, 6–8 feet is enough.

- Tip: Always buy a machine that can dig slightly deeper than your typical requirement. Operating a machine at its absolute maximum limit wears it out faster.

2. Operating Weight and Transport

Can you move it?

- Check the towing capacity of your current truck. If your truck is rated for 7,000 lbs, you cannot buy a 7,000 lb excavator because you must also account for the weight of the trailer (which can be 2,000+ lbs).

- Buying a bigger excavator might force you to buy a bigger truck, doubling your investment cost.

3. Hydraulic Capacity (Auxiliary Hydraulics)

If you plan to use attachments (augers, hammers, mulchers), the hydraulic flow (Gallons Per Minute or GPM) matters.

- Standard Flow: Good for thumbs and buckets.

- High Flow: Required for intense attachments like brush mulchers.

- Ensure the machine has auxiliary hydraulic lines that run to the boom. Most modern machines are equipped with this feature, but it is important to double-check the used inventory.

4. Comfort and Cab Configuration

Are you operating this for 1 hour a week or 8 hours a day?

- Open Canopy (ROPS): Cheaper, easier to hop in and out of, and better visibility. Ideal for mild climates.

- Enclosed Cab (HVAC): Essential for rain, snow, or extreme heat. Includes A/C and heat. It keeps the operator cleaner and reduces noise fatigue.

5. Tracks: Rubber vs. Steel

- Rubber: Standard for minis. Rubber provides excellent traction, a smooth ride, and does not damage the pavement.

- Steel: Essential for jagged rocks, demolition debris, or very aggressive terrain that shreds rubber.

- Hybrid (Roadliner): Steel pads with rubber inserts.

6. Dealer Support and Brand

Machines break. This is an inescapable reality.

- Do not just buy the cheapest import brand. Buy the brand that has a dealership 20 minutes from your house.

- When a hydraulic hose bursts on a Tuesday morning, the difference between a 2-hour fix (local dealer) and a 2-week wait for parts (obscure brand) is money lost.

7. New vs. Used

- New: Warranties (often 2-3 years), the latest technology (telematics, fuel efficiency), and 0% financing offers.

- Used: Lower upfront cost. However, verify the condition of the pins and bushings (is the bucket wobbly?) and the tracks (are they cracked?).

Market Spotlight: Typhon Machinery

The market has traditionally been dominated by giants like Caterpillar, Kubota, and Bobcat. However, these premium brands come with premium price tags that are often out of reach for homeowners or startup contractors.

This gap in the market has been filled by disruptors like Typhon Machinery. Typhon has gained massive popularity for offering affordable, reliable, and “complete” packages.

Who is Typhon For?

Typhon focuses on the value segment. They are designed for the homesteader, the DIY renovator, the farmer, and the small contractor who needs a reliable machine but doesn’t want to spend $60,000.

Notable Typhon Models

Typhon Terror X & XI Storm (1-Ton Class):

- The Engine: Often powered by Briggs & Stratton gas engines. This is a brilliant move for DIYers because any small-engine mechanic can fix them, and parts are available at local hardware stores.

- The Use Case: Perfect for backyard trenching, planting trees, and laying electrical conduit. They fit through gates and are easy to tow.

Typhon Terror XIII Pro (1.3-Ton Class):

- The Upgrade: Usually features a Honda engine (legendary reliability) and often includes joystick controls and an articulating boom for better precision.

Typhon Terror XXV (2.5-Ton Class):

- The Pro Machine: This steps up to a Kubota diesel engine. Kubota is the gold standard for small diesel engines. This machine offers the torque and longevity needed for daily commercial use.

- Comfort: Available with a fully enclosed cab (Typhon Prestige models) with heat and A/C.

The Typhon Advantage

Most big brands sell you the bare machine. You have to pay extra for a bucket, extra for a roof, and extra for a thumb. Typically, Typhon offers complete packages. When you buy a Typhon, it usually comes standard with:

- A digging bucket.

- A hydraulic thumb, which is crucial for retrieving debris, is also included.

- A canopy or cab.

- A basic tool kit.

Frequently Asked Questions (FAQ)

Here are the most common questions people ask before buying or renting.

Q: Do I need a license to operate a mini excavator?

A: Generally, no, provided you are operating it on private property. You do not need a license to dig a pond in your backyard. However, if you are using it for commercial work, or if you ever drive it on a public road, you may need a hoisting license or specific DOT certifications depending on your state/country.

Q: Can a mini excavator dig through rock?

A: A bucket alone cannot dig through solid bedrock. However, if you equip the excavator with a hydraulic breaker (hammer) attachment, it can chip away at rock and concrete. It takes time, but it works.

Q: Which is better: gas or diesel? A:

- Diesel (e.g., Kubota, Yanmar): The professional choice. Offers higher torque, better fuel efficiency, and engines that can last 5,000+ hours. However, they are louder and more expensive to repair.

- Gas (e.g., Briggs, Honda): The DIY choice. Gas engines, such as Briggs and Honda, are easier to start in cold weather, require no glow plugs, are cheaper to purchase, and are simpler to find a mechanic for. Great for intermittent use.

Q: What is a thumb, and is it necessary?

A: A thumb is a hinged metal claw that opposes the bucket. Yes, it is necessary. Without a thumb, you can only dig. With a thumb, you can grab. You can pick up a specific rock, pull a fence post out of the ground, or carry a log. It doubles the machine’s usefulness.

Q: How do I transport it? A: You need a trailer rated for the payload.

- Example: If your excavator weighs 4,000 lbs, do not use a “3,500 lb axle” utility trailer. You need a trailer with at least two 3,500 lb axles (7,000 lb GVWR) to handle the weight of the machine plus the trailer itself safely.

Q: Can I use a mini excavator to push snow?

A: Yes! Many people attach a straight blade or a snow pusher box to the front. The tracks provide excellent traction in snow.

Conclusion

The mini excavator is more than just a piece of equipment; it is an enabler. It allows a single person to perform the work of ten. It simplifies laborious manual tasks into simple lever operations.

Whether you choose a premium conventional machine or a high-value option like the Typhon Terror series, the key is to match the specs to your specific needs. By understanding the weight classes, attachments, and capabilities outlined in this guide, you are now ready to make an informed decision and dig in.